Compressor type chip temperature reducing system

A technology of refrigeration compressors and chips, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of high-power chips with small area and high heat generation that cannot be effectively cooled, and achieve the effect of improving refrigeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

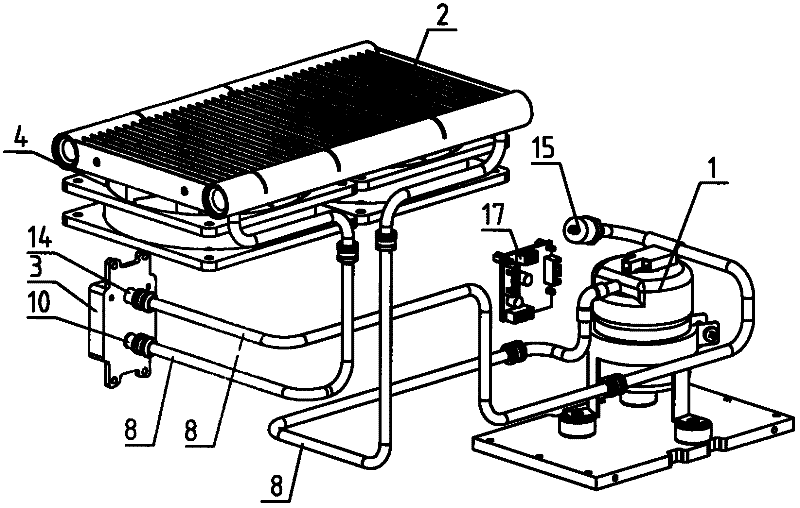

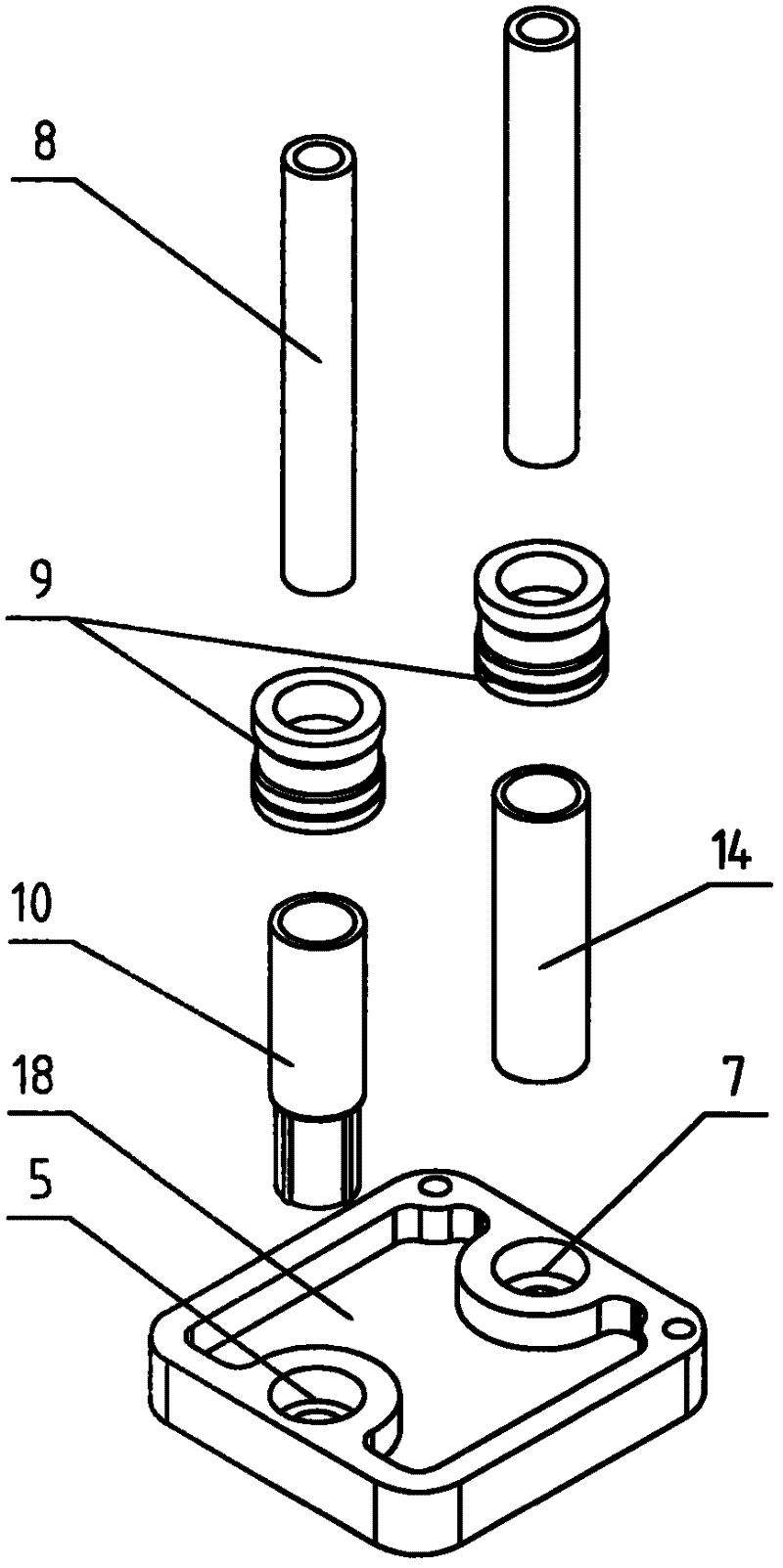

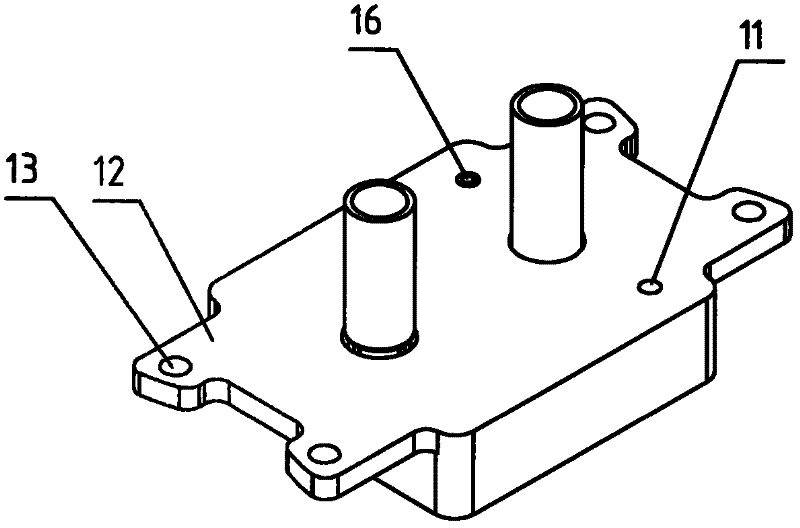

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the micro-refrigeration compressor type chip cooling system of the present invention includes a micro-refrigeration compressor 1, a condenser 2 and a microchannel evaporative cold head 3; The channel evaporative cold head 3 has a sealed installation cavity 18 for filling thermal insulation materials, and the thermal insulation material is filled in the installation cavity 18 according to actual needs. Next to the installation cavity 18, there are micro-channel evaporative cold head inlets 5 and micro-channel evaporative cold head Outlet 7, on the back of the installation cavity 18, there are micro-channel evaporative cold head internal flow channels 6 that communicate with the micro-channel evaporative cold head inlet 5 and the micro-channel evaporative cold head outlet 7 respectively, and a refrigerant is fixedly installed on the micro-refrigeration compressor 1 Filling pipe 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com