Wire stroking device for repairing broken strands of extra-high-voltage (EHV) transmission lines

A technology for power transmission lines and repair operations, which is applied to equipment for connecting/terminating cables, etc., can solve the problems of low efficiency, high labor intensity and high risk of manual line drawing, and achieves light weight, reduced labor intensity, and the process of drawing lines. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

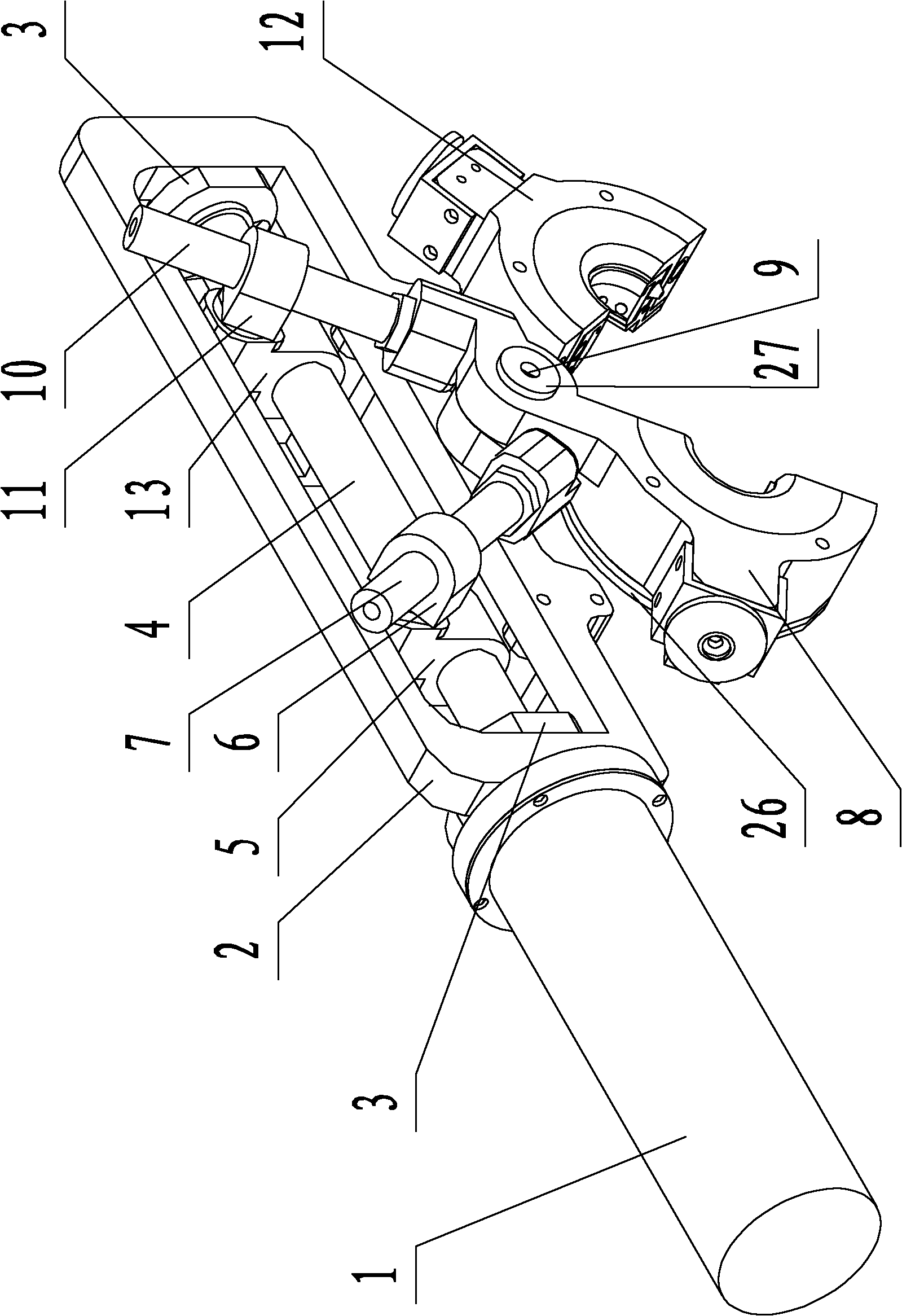

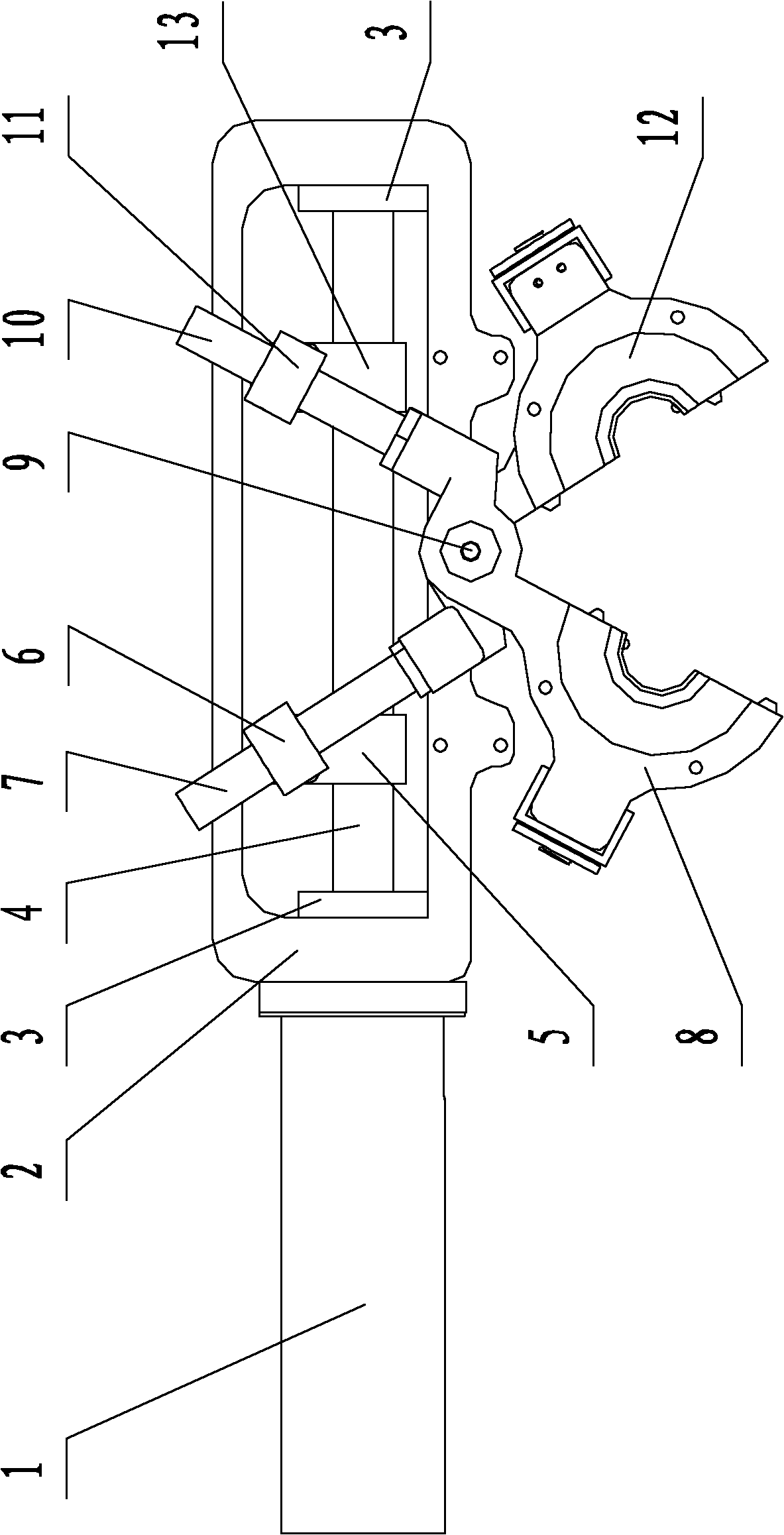

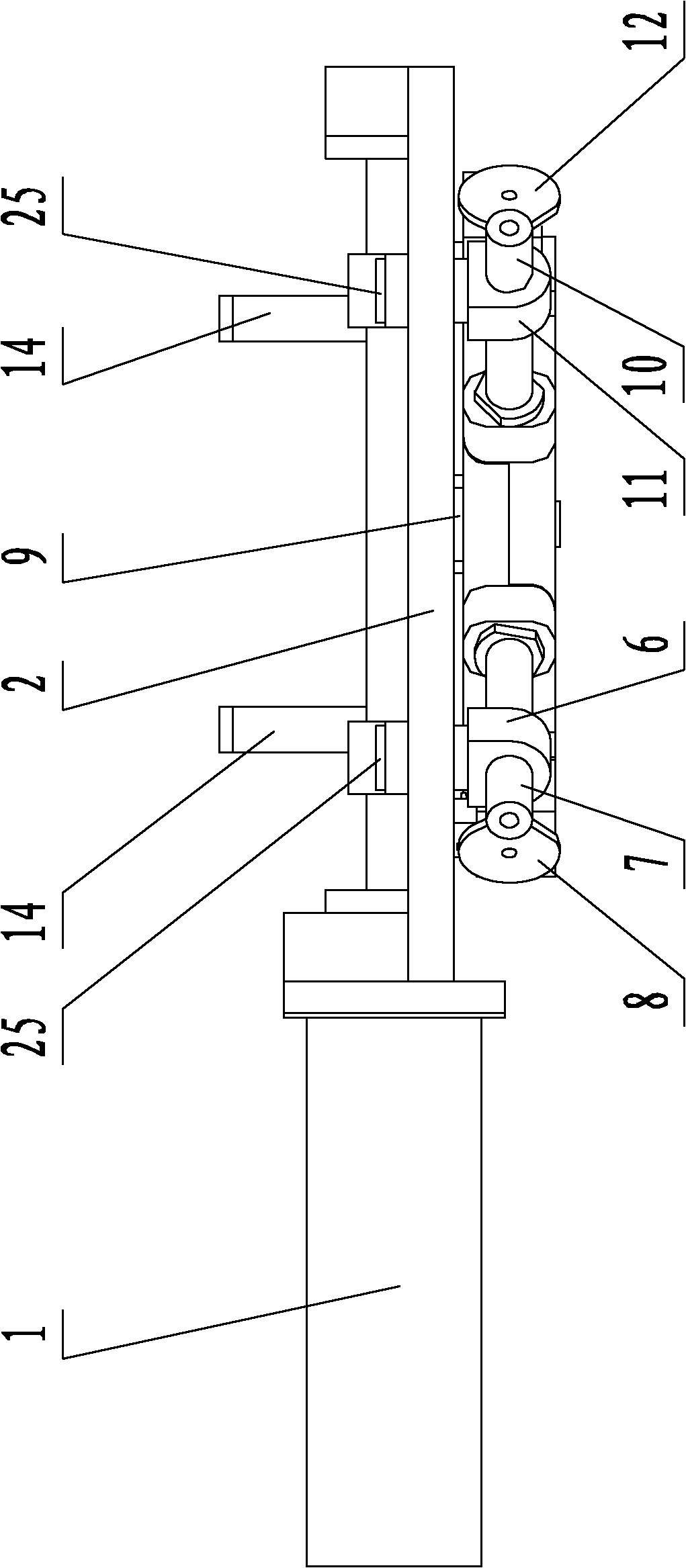

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] Such as Figure 1~5 As shown, the present invention includes opening and closing motor 1, fixed plate 2, copper sleeve 3, lead screw 4, left nut 5, left guide sleeve 6, left guide rod 7, left threader 8, rotating shaft 9, right guide Rod 10, right guide sleeve 11, right threader 12, right nut 13 and bracket 14, wherein the fixed plate 2 is a rectangular frame structure, and the two inner walls in the height direction of the fixed plate 2 are fixedly connected with copper sleeves 3, screw The two ends of 4 are supported by two copper sleeves 3, one end of which is pierced by the fixed plate 2, connected with the output shaft of the opening and closing motor 1 fixed on the fixing plate 2, driven by the opening and closing motor 1, with the opening and closing The output shaft of motor 1 rotates. On the lead screw 4, there are left screw nut 5 and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com