Production-increasing device for ultrasonic treatment on plant seeds

A plant seed and ultrasonic treatment technology, applied in the fields of seed and rhizome treatment, application, agriculture, etc., can solve the problems of inability to meet the needs of large-scale production in agriculture and forestry, simplicity, and inability to continuously automate operation, and achieve large-scale continuous Agricultural production, simple operation, convenient application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

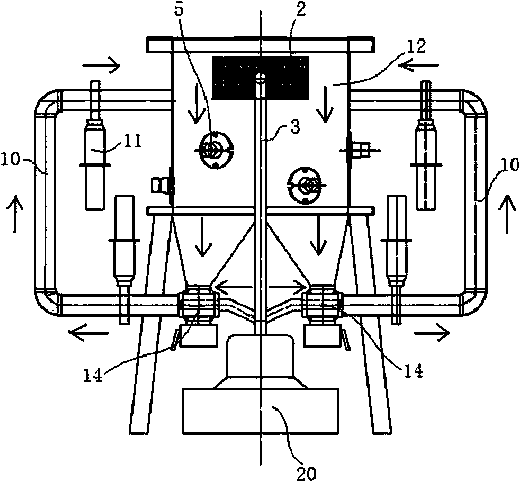

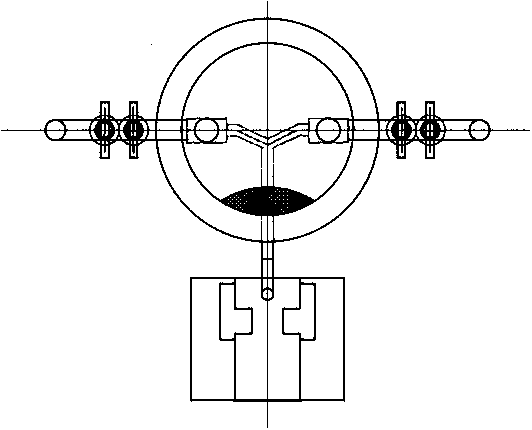

[0037] Sonic treatment of plant seed production devices, such as figure 1 and figure 2As shown, at least one ultrasonic processing container 12 is included, and several ultrasonic transducer devices 5 for ultrasonic irradiation are installed on the side wall of the ultrasonic processing container 12, and at least one valley liquid outlet is provided at the bottom of the ultrasonic processing container 12 , the lower part of the valley liquid outlet is connected to the valley liquid confluence driving pressure circulation function device 14, the valley liquid confluence driving pressure circulation function device 14 is connected to the lower end of the ultrasonic functional circulation pipe 10, and the upper end of the ultrasonic functional circulation pipe 10 is connected to the ultrasonic functional circulation pipe 10. The upper and side walls of the processing container 12 are connected to each other, and the ultrasonic functional circulation pipe 10 is provided with seve...

Embodiment 2

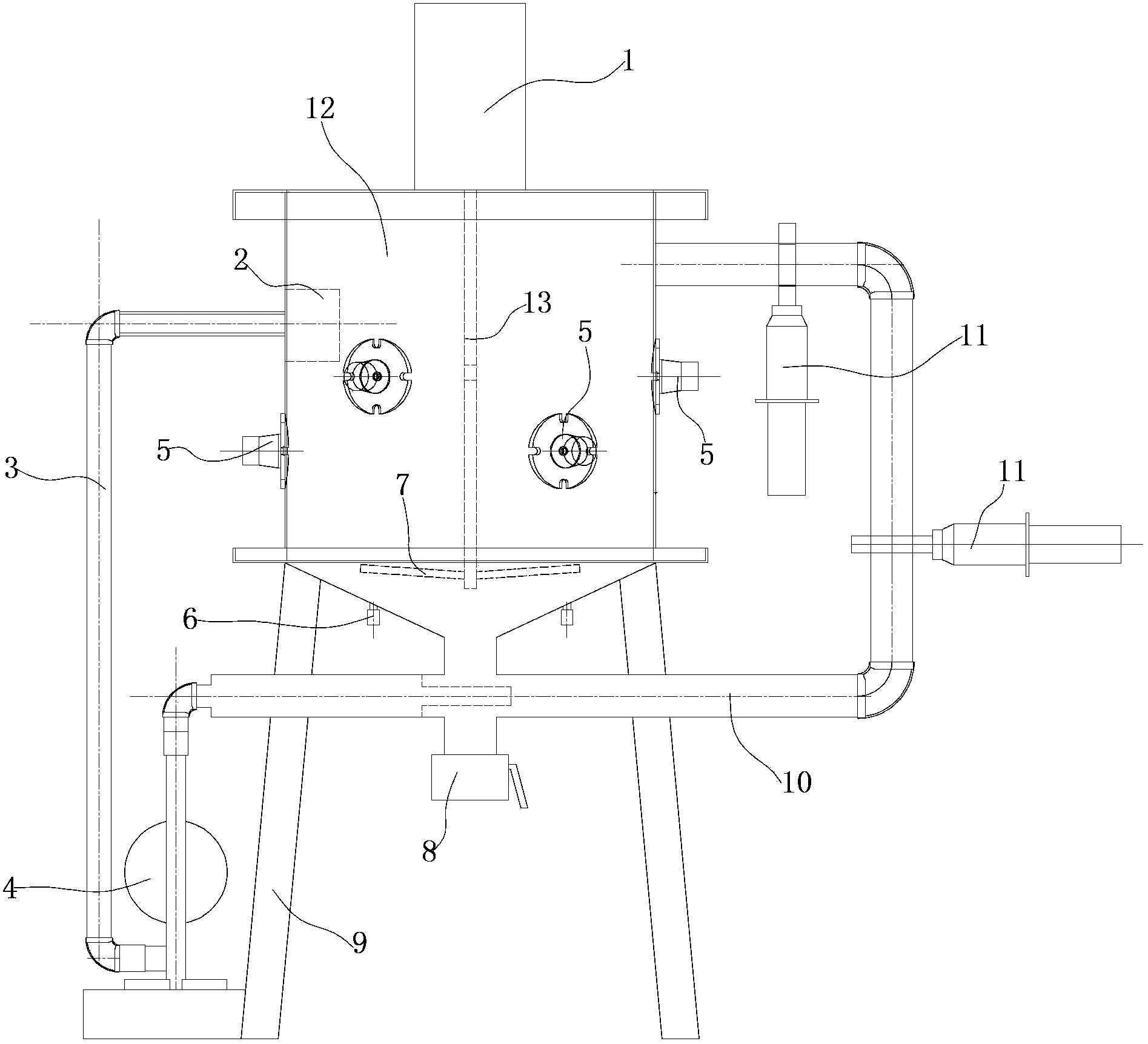

[0040] Such as image 3 and Figure 4 As shown, on the basis of Example 1, the bottom of the ultrasonic treatment container 12 is provided with two funnel parts, and below the outlet of the valley liquid under the funnel parts, a functional device 14 for converging and driving pressure circulation of the grain liquid is respectively provided. The valley fluid confluence drive pressure circulation function device 14 is connected with the ultrasonic function circulation pipe 10 and the lower end of the circulation drive pipe 3 . The upper end of the ultrasonic function circulation tube 10 is connected to the upper side wall of the ultrasonic treatment container 12, and the ultrasonic function circulation tube 10 is provided with several clamp-type ultrasonic transducer devices 11; the lower end of the circulation drive tube 3 is respectively connected to The valley liquid confluence drive pressure circulation function device 14 is connected to the connection of the ultrasonic f...

Embodiment 3

[0042] Such as Figure 7 and Figure 8 As shown, the bottom of the ultrasonic treatment container 12 is provided with three funnel parts, and the bottom of the funnel parts is respectively provided with a valley liquid confluence, pressure displacement and circulation function device 14. Circulation pipe 10 is connected under, the upper end of described ultrasonic function circulation pipe 10 is connected with the upper end side wall of ultrasonic treatment container 12, and described ultrasonic function circulation pipe 10 is provided with several clamp type ultrasonic transducer devices 11; The lower ends of the tubes 3 are respectively connected to the joints of the valley fluid confluence drive pressure circulation function device 14 and the ultrasonic function circulation tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com