Split welding type car door anti-collision beam

A technology of anti-collision beams and car doors, applied in the field of automotive parts, can solve the problems of not fully utilizing the potential of materials, waste, and increased quality of anti-collision beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

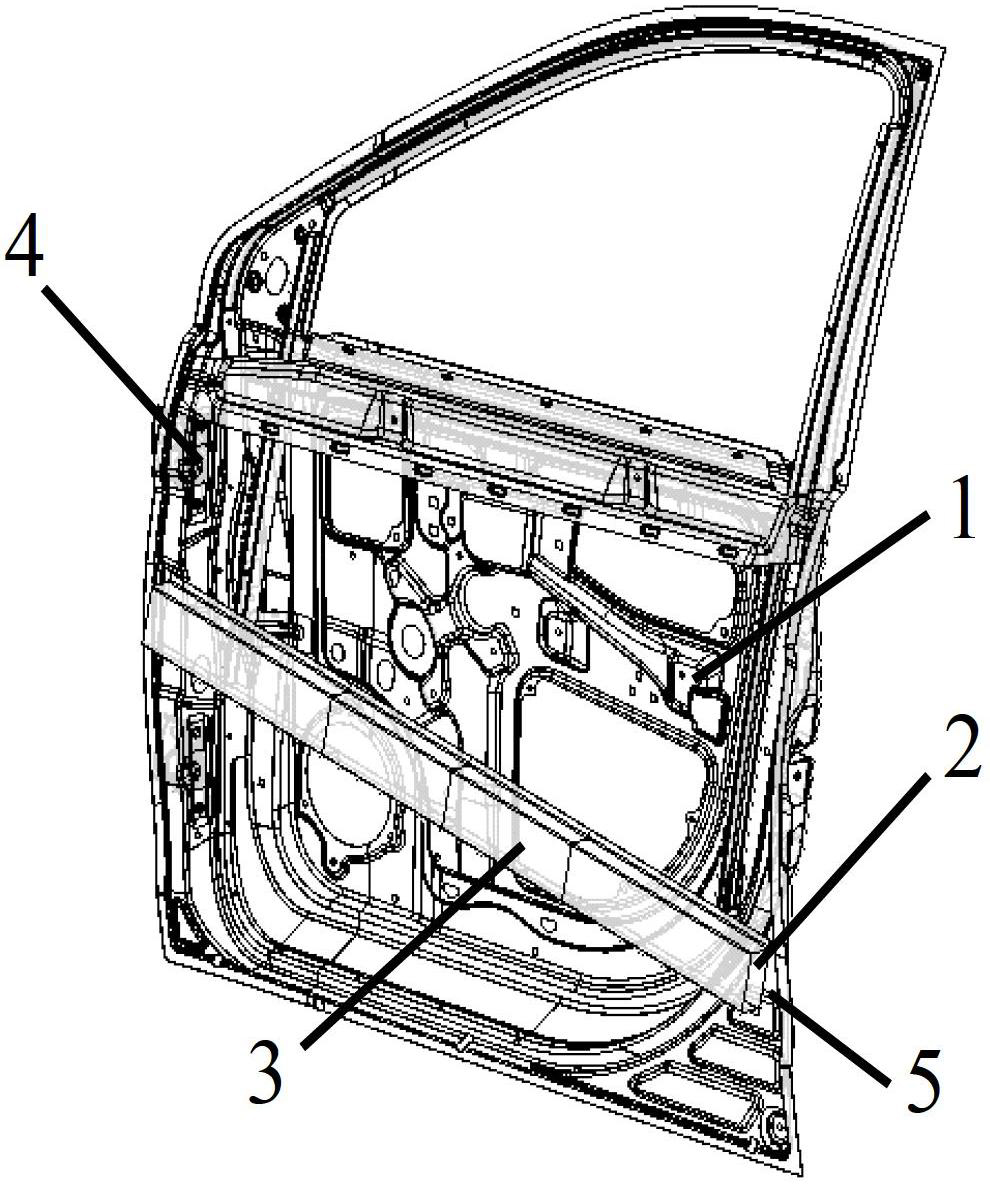

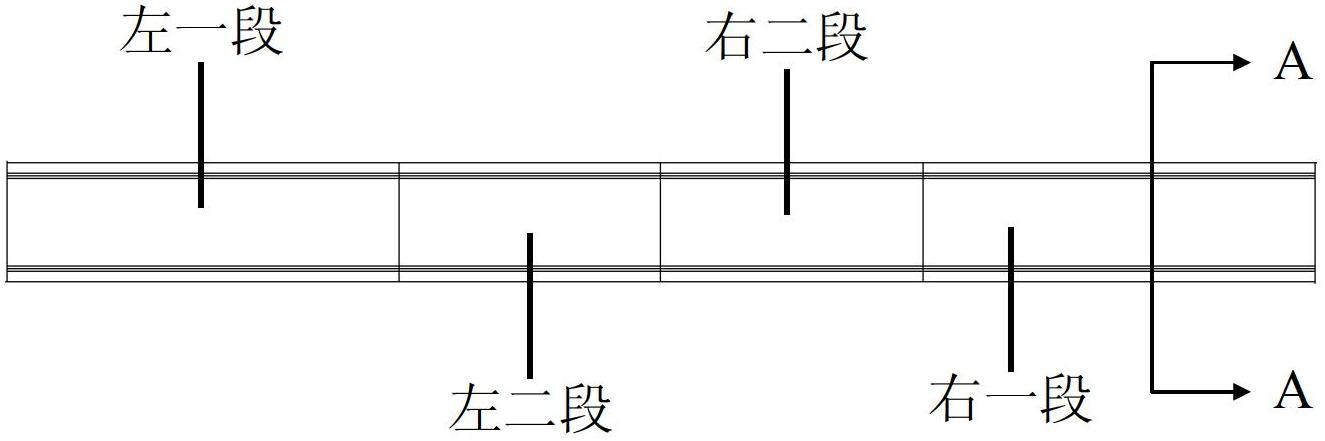

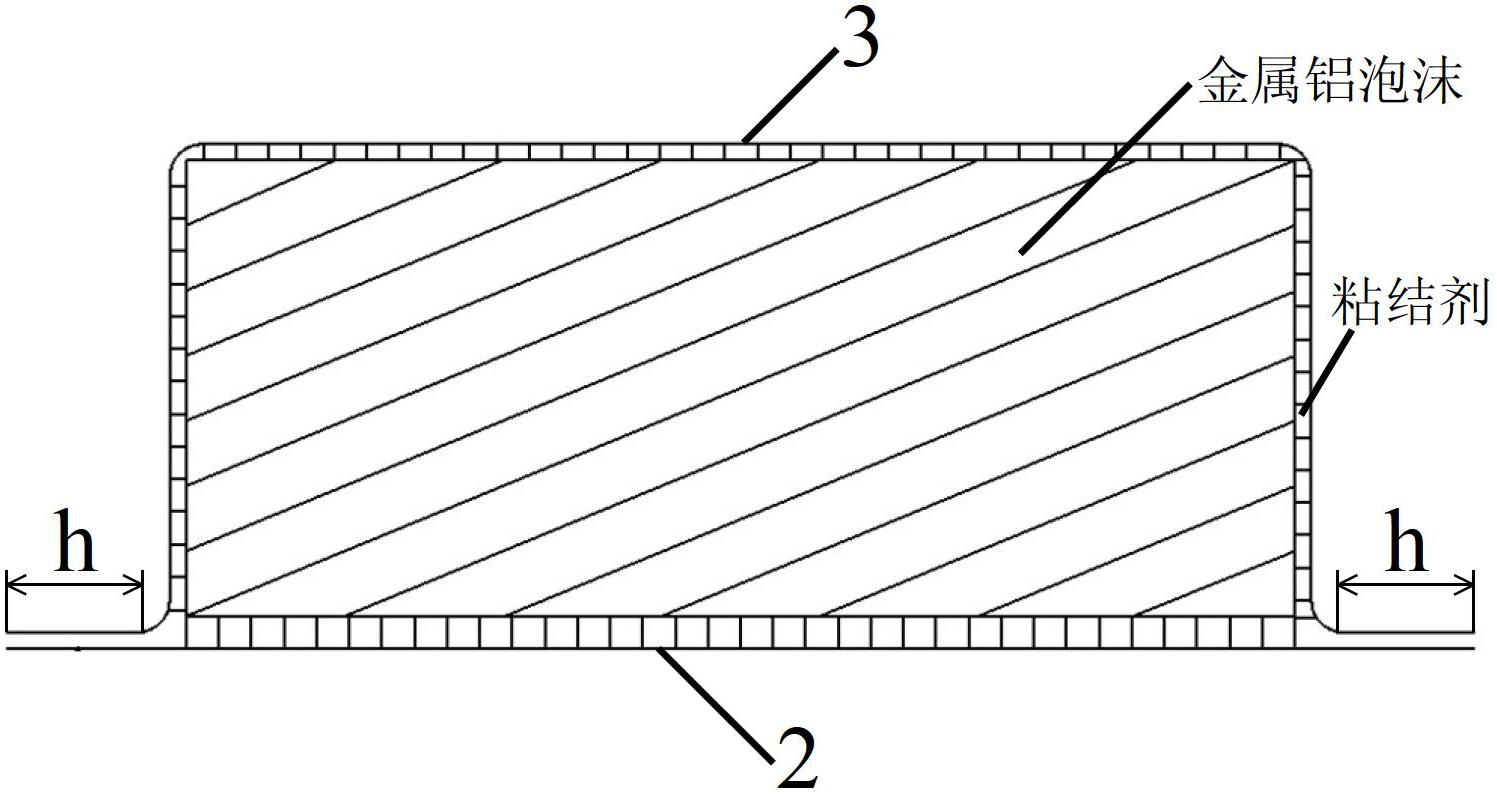

[0013] Such as figure 1 As shown, a tailor-welded door anti-collision beam with a closed-loop cross section and a through-hole inner cavity is arranged on the inner panel 1 of the vehicle door, and the anti-collision beam is firmly connected with the inner panel 1 of the vehicle door. The anti-collision beam is composed of the anti-collision outer panel 3 and the anti-collision cover plate 2, and the anti-collision cover plate 2 is fixedly connected with the door inner panel 1. The anti-collision cover plate 2 of the anti-collision beam is a long rectangular plate, the outer plate 3 of the anti-collision beam is U-shaped, and the outer plate 3 of the anti-collision beam is welded into a long rectangular plate by four rectangular flat plates. The outer panel 3 of the impact beam is divided into the left section, the second section from the left, the section from the right and the second section from the right, and then the tailor-welded rectangular plate is bent to form a U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com