Component having at least one MEMS element and method for the manufacture thereof

A component and component technology, which is applied in the components of TV systems, semiconductor/solid-state device components, and manufacturing microstructure devices, etc., can solve the problems of increased manufacturing costs, expensive microphone packaging, and increased packaging area, and can eliminate The effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 50

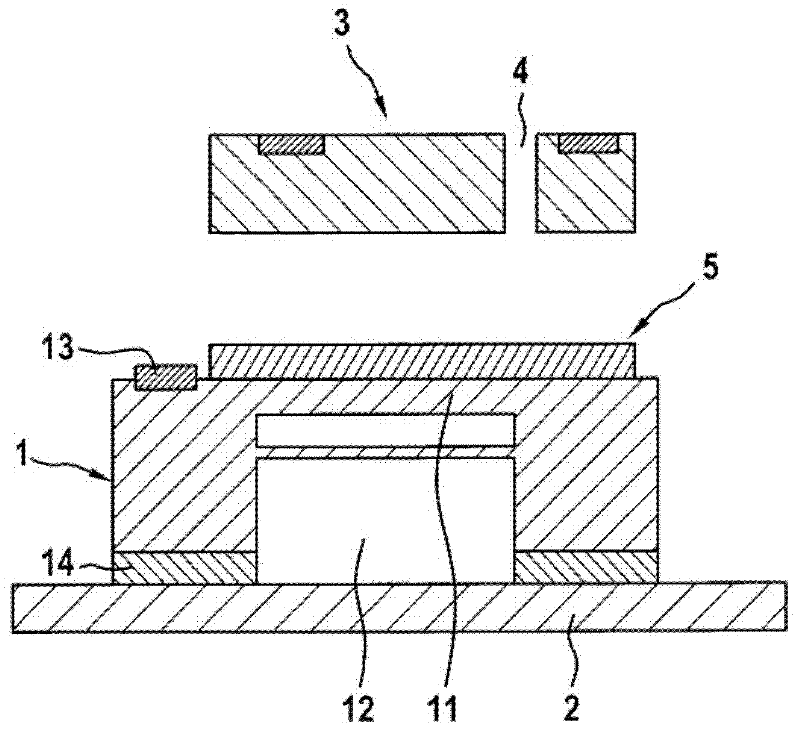

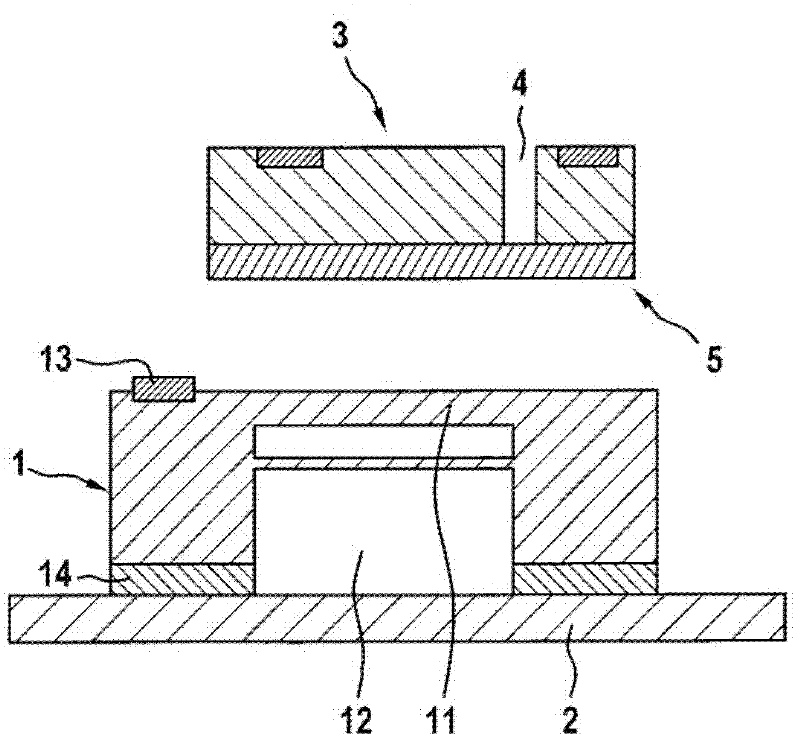

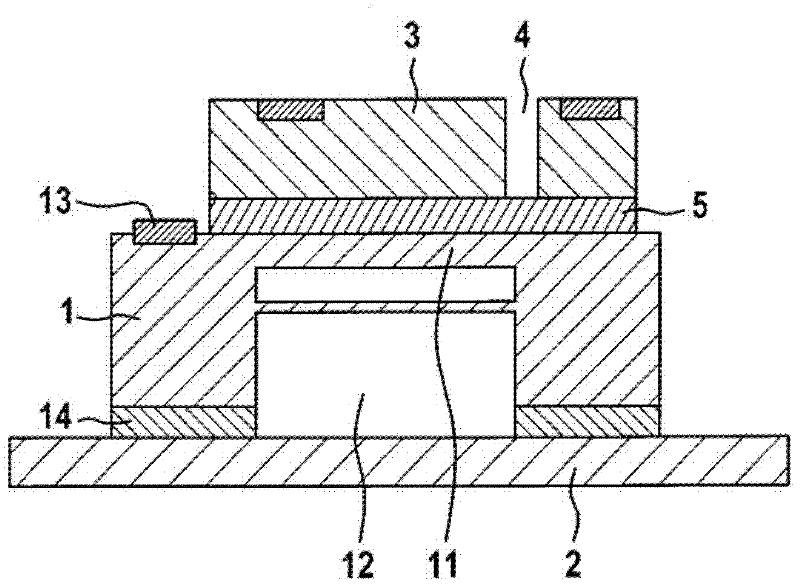

[0044] Figure 5 A further embodiment 50 of a microphone package according to the invention is shown, which has a MEMS microphone assembly 1 which is mounted with the back side of the assembly on a flat support 2, so that below the diaphragm structure 11 The cavity 12 forms together with the support 2 the rear volume of the microphone assembly 1 . In the exemplary embodiment shown here, the microphone assembly 1 is not connected by means of wire bonding, but via connection terminals 53 on the rear side of the assembly. Furthermore, the microphone package 50 comprises an ASIC 3 with a through-hole 4 , which is arranged in flip-chip technology, ie facing downwards, on the microphone assembly 1 and is spaced apart from the diaphragm structure 11 . In the exemplary embodiment shown here, the ASIC 3 is connected to the microphone assembly 1 via a structured adhesive layer 25 which remains permanently in the microphone package 50 and extends only over the frame area of the diaphr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com