Base component of bladeless fan

A bladeless fan and component technology, applied in the direction of machines/engines, non-volume pumps, mechanical equipment, etc., can solve the problems of complex structure of the fan base, and achieve the effect of simple structure, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

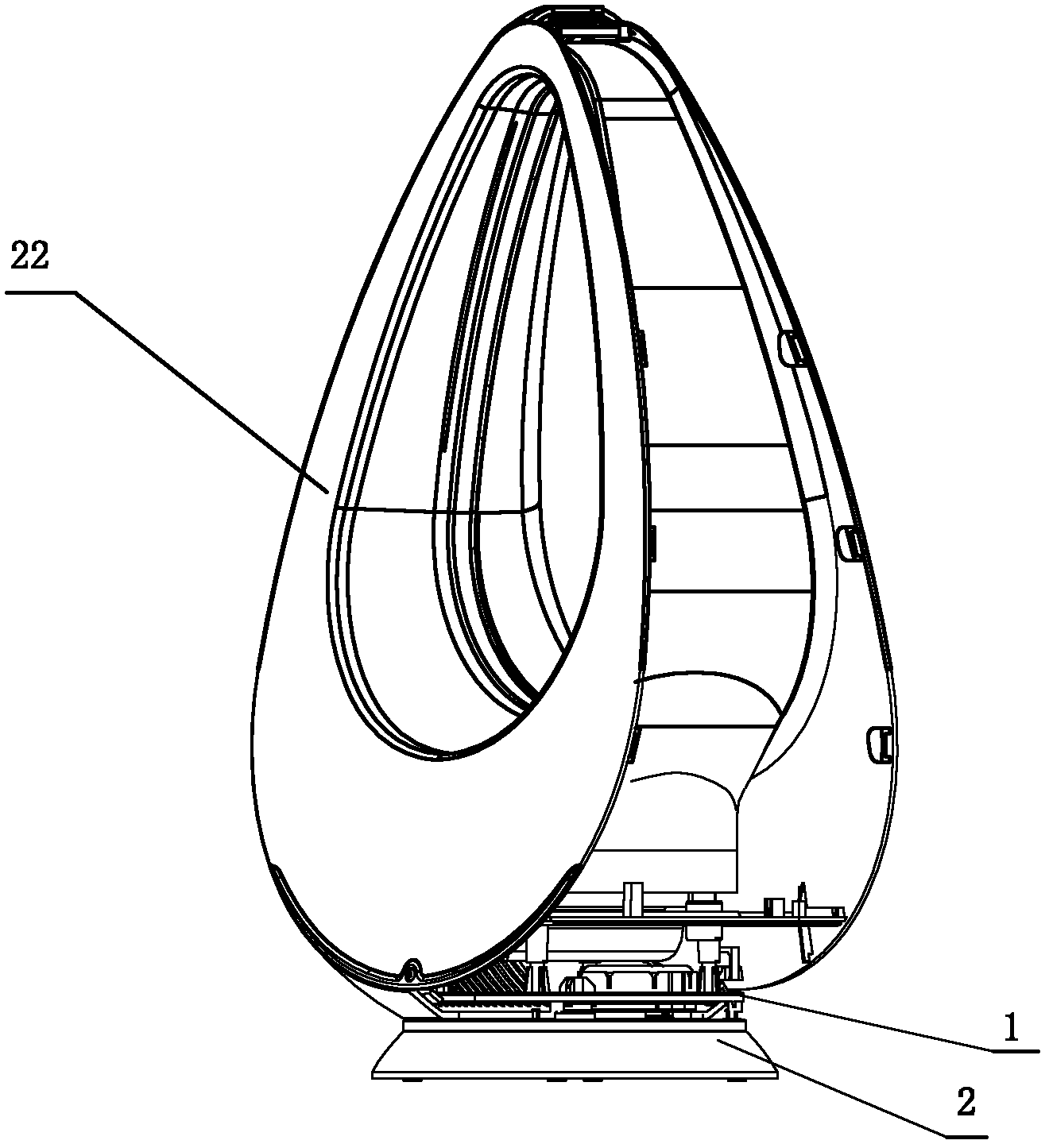

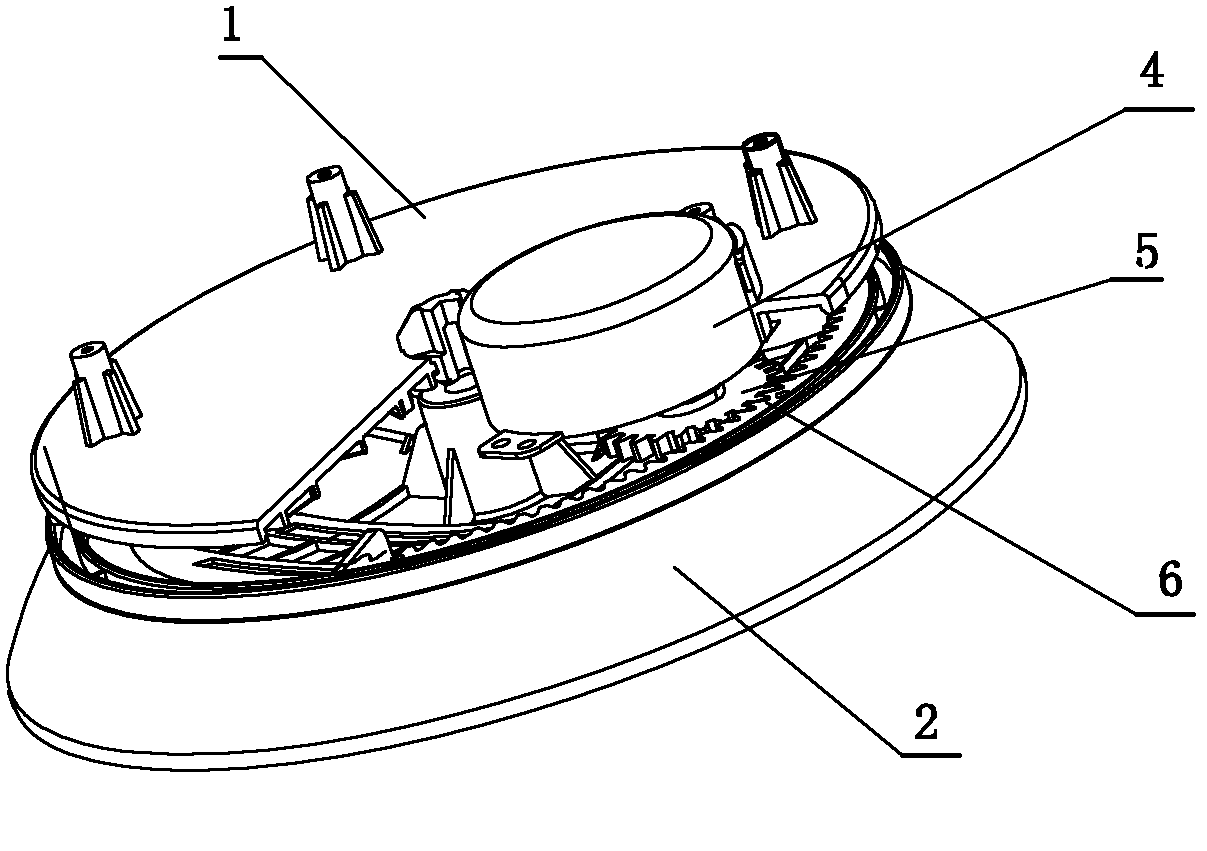

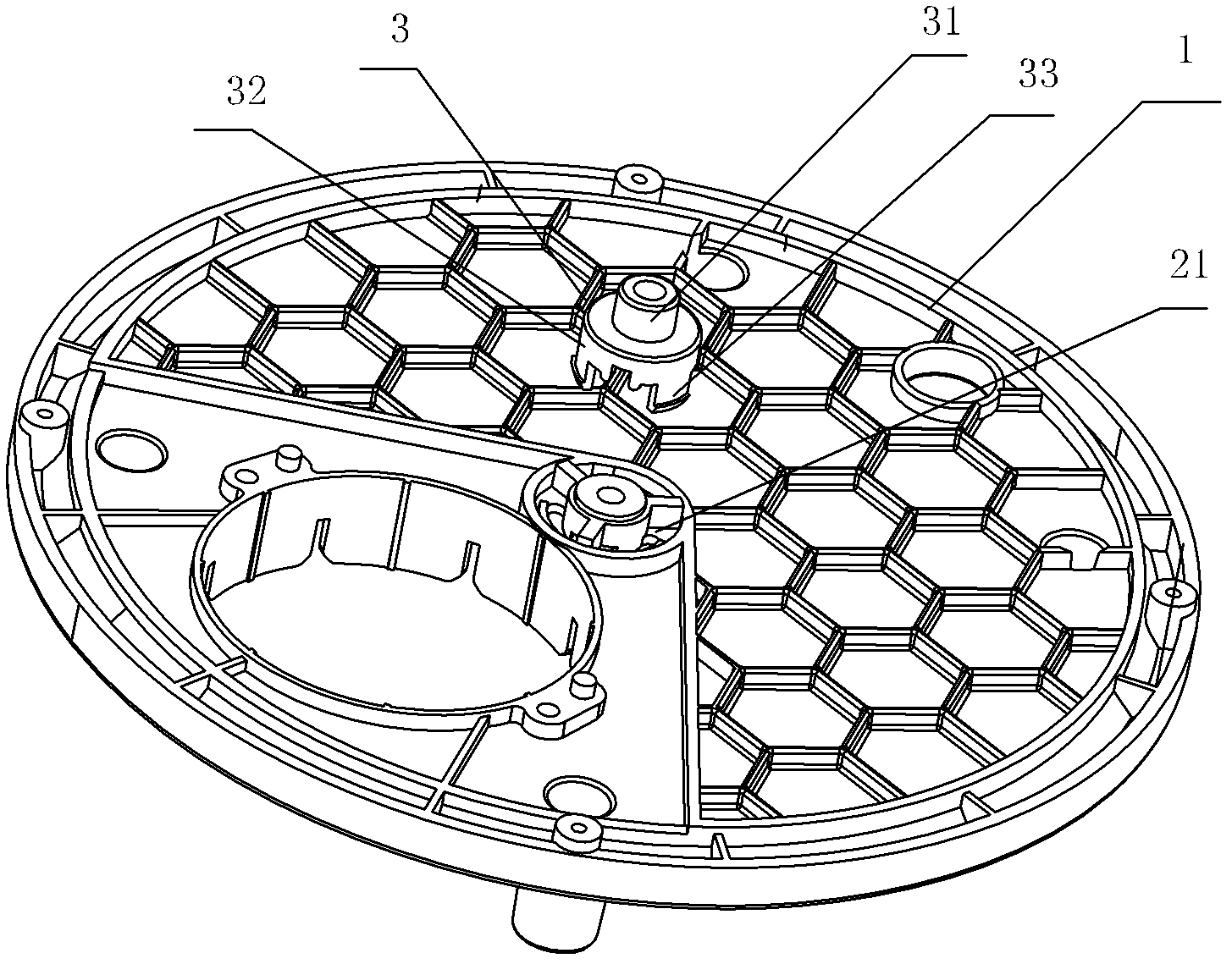

[0024] A bladeless fan base assembly includes a rotating disc 1 for supporting a fan assembly 22 and a chassis assembly 2. The center of the rotating disc 1 is axially connected to the center of the chassis assembly 2 through a rotating shaft assembly 3, and the rotating disc 1 is located at the center of the chassis assembly 2. Above, the rotating disk 1 is provided with a motor 4, and a rotating mechanism is provided between the rotating disk 1 and the chassis assembly 2. The motor 4 drives the rotating mechanism to rotate the rotating disk 1. The chassis assembly includes a fixed base 7 and a movable plate 8, and a fixed base 7 The upper surface is a concave spherical surface, the lower surface of the movable plate 8 is a convex spherical surface, the upper surface of the fixed base 7 and the lower surface of the movable plate 8 cooperate with each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com