Pump-free lithium ion flow battery and preparation method of electrode suspension solution

A liquid flow battery and lithium-ion technology, applied in fuel cells, fuel cell additives, regenerative fuel cells, etc., can solve problems such as electrode suspension leakage, potential safety hazards, water-oxygen gas contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

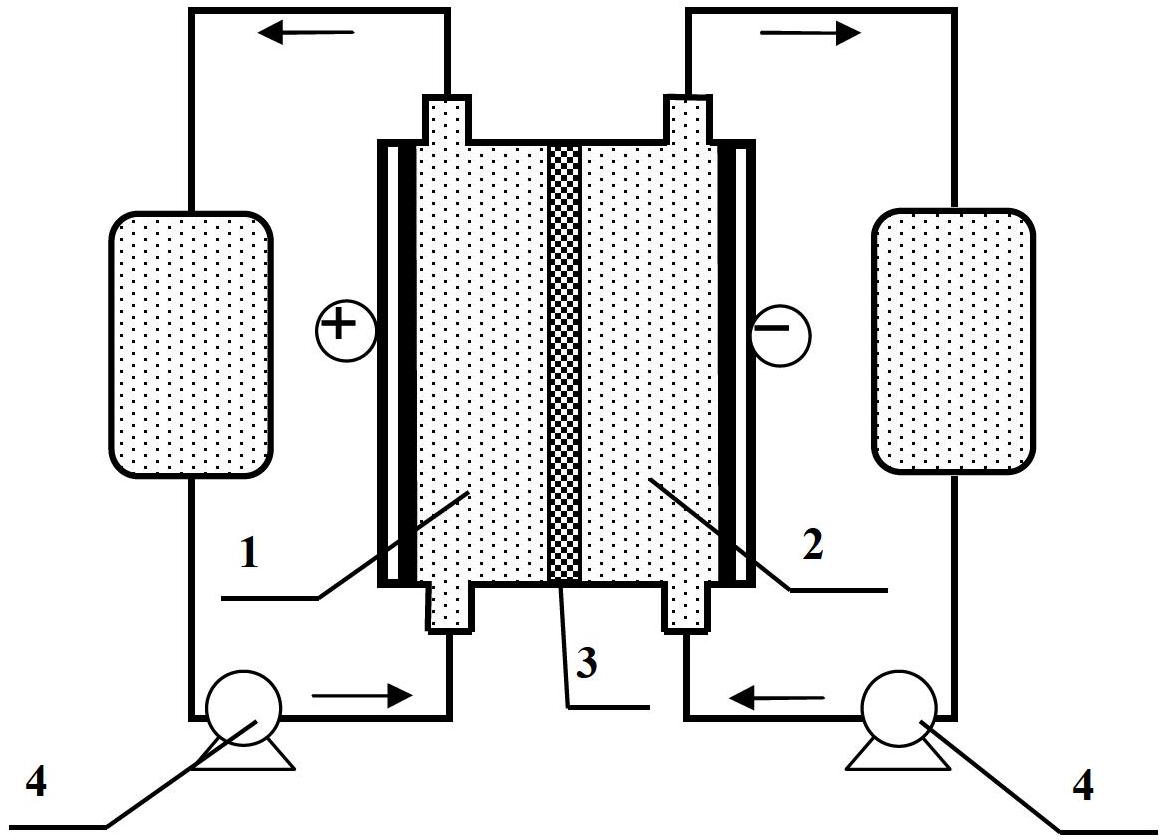

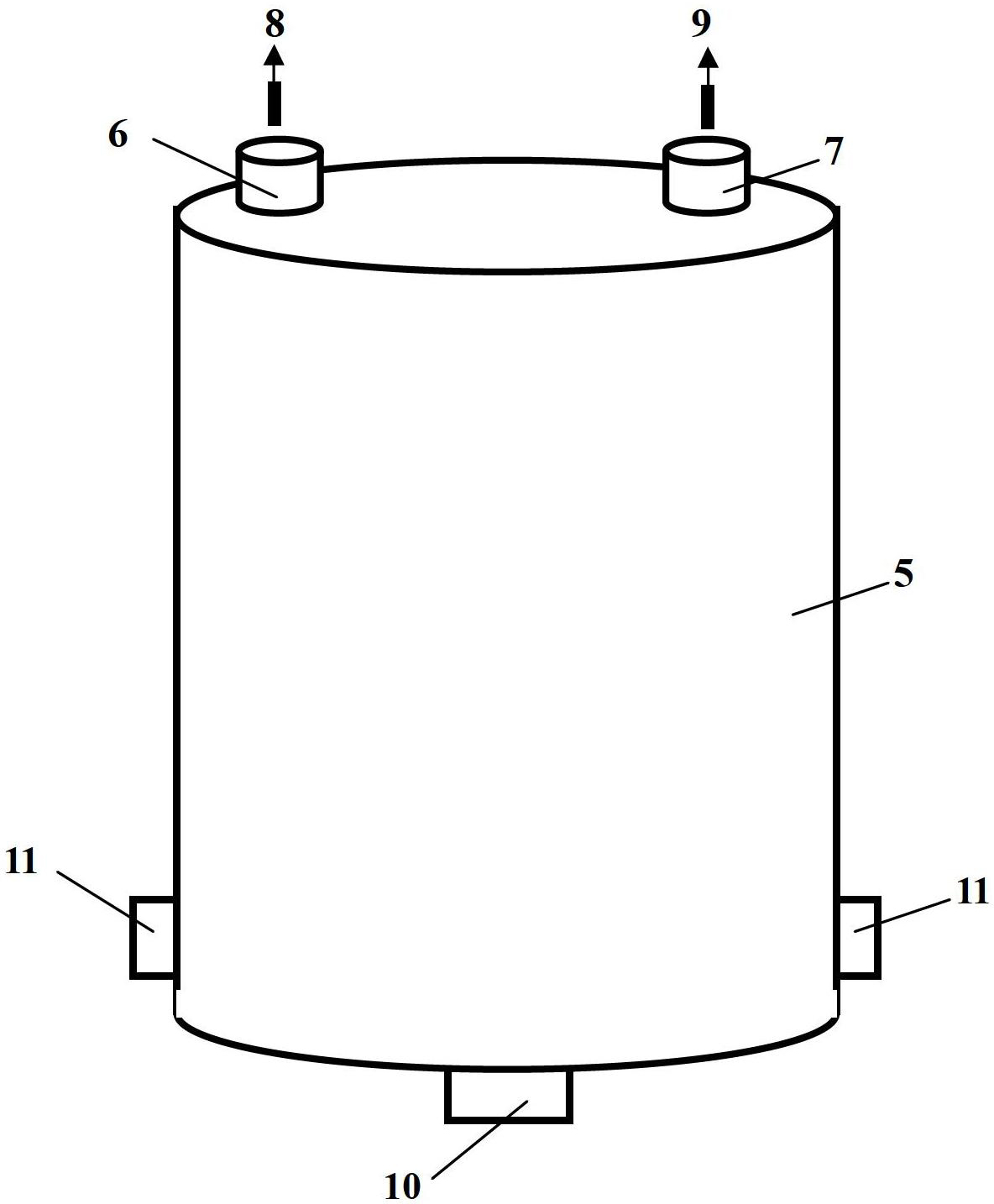

[0050] This embodiment provides a pumpless lithium ion flow battery subsystem.

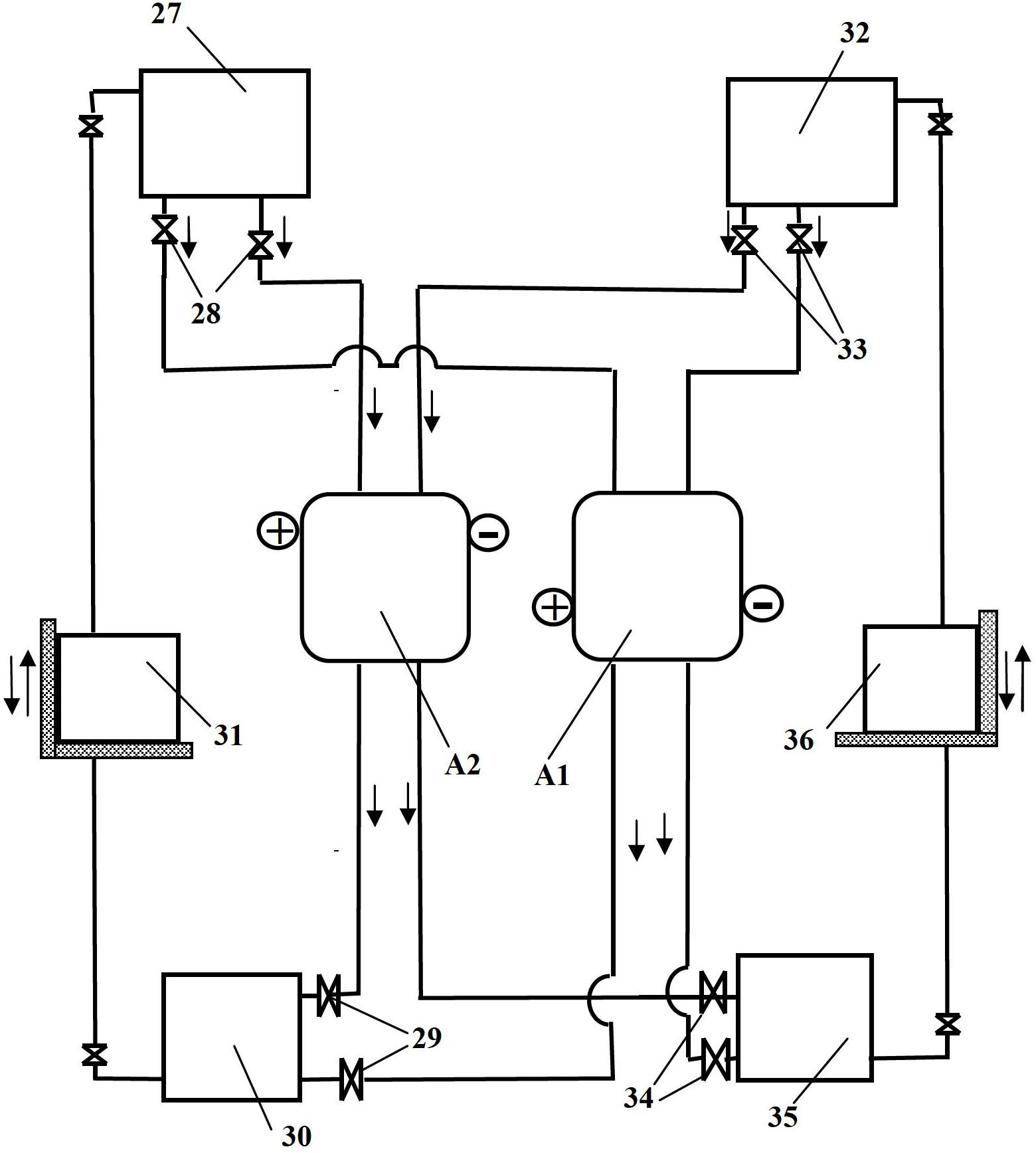

[0051]A pumpless lithium ion flow battery subsystem, the battery subsystem includes 3 battery reactors (18), 1 positive electrode liquid inlet tank (16), 1 positive electrode liquid outlet tank (20), 1 negative electrode liquid inlet tank Liquid tank (21), a negative electrode liquid outlet tank (24). The circuit connection mode among the three battery reactors (18) is parallel connection. The positions of the positive electrode liquid inlet tank (16), the positive electrode reaction chamber (1), and the positive electrode liquid outlet tank (20) are arranged in order from high to low; the negative electrode liquid inlet tank (21), the negative electrode reaction chamber (2), and the negative electrode liquid outlet tank The positions of (24) are arranged in order from high to low. Among them, the positive electrode reaction chambers (1) of the three battery reactors (18) are respectively connec...

Embodiment 2

[0053] This embodiment provides a pumpless lithium ion flow battery subsystem.

[0054] A pumpless lithium ion flow battery subsystem, the battery subsystem includes 3 battery reactors (18), 1 positive electrode liquid inlet tank (16), 1 positive electrode liquid outlet tank (20), 1 negative electrode liquid inlet tank Liquid tank (21), a negative electrode liquid outlet tank (24). The circuit connection mode among the three battery reactors (18) is parallel connection. The positions of the positive electrode liquid inlet tank (16), the positive electrode reaction chamber (1), and the positive electrode liquid outlet tank (20) are arranged in order from high to low; the negative electrode liquid inlet tank (21), the negative electrode reaction chamber (2), and the negative electrode liquid outlet tank The positions of (24) are arranged in order from high to low. Among them, the positions of the three battery reactors (18) are arranged from high to low, the three positive ele...

Embodiment 3

[0056] This embodiment provides a pumpless lithium ion flow battery subsystem.

[0057] A pumpless lithium ion flow battery subsystem, the battery unit includes 9 battery reactors (18), 1 positive electrode liquid inlet tank (16), 1 positive electrode liquid outlet tank (20), 1 negative electrode liquid inlet tank (21), 1 negative electrode liquid outlet tank (24). Among them, 3 battery reactors (18) are a group, and the 3 battery reactors (18) in each group are connected by pipes according to the method in Example 2, and the 3 sets of battery reactors (18) are connected according to Example 1. Connect the pipes in the same way.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com