Load remote automatic control power supply device

A power supply device and remote start-up technology, applied in the direction of circuit devices, electrical components, etc., can solve problems such as power consumption, potential safety hazards, and lack of automatic cut-off function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

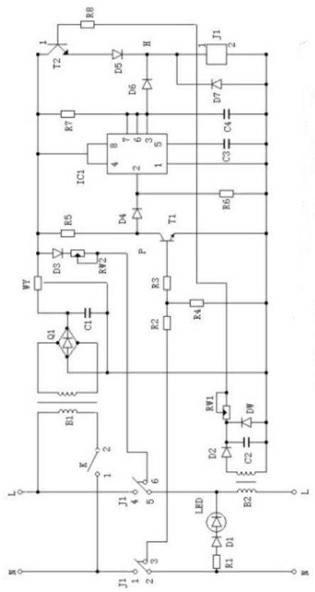

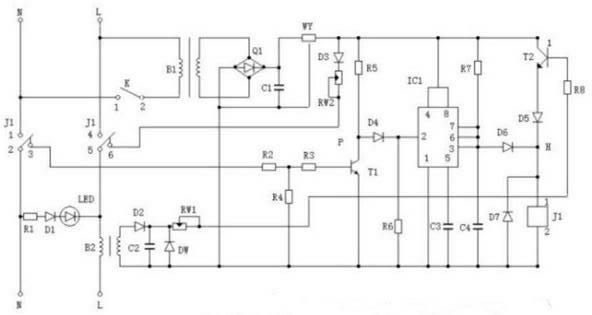

[0016] like figure 1 As shown: the single-phase electric load remote automatic control power supply device described in this embodiment is composed of a complete machine working power supply circuit, a remote start command recognition circuit, a power supply, power-off execution control circuit and an on-load continuous power supply recognition control circuit. The external line (DC impedance) in this embodiment refers to the loop line between the front end of the power control switch and the load terminal, and the power control switch refers to the switch blade.

[0017] The working power circuit of the complete machine is composed of a switch K, a transformer B, a bridge rectifier stack Q1, a filter capacitor C1, and a three-terminal voltage stabilizing circuit WY. The working process is: the AC power is sent to the primary of the transformer B1 through the switch K, and after being stepped down by the transformer, it is sent to the bridge pile Q1 for rectification, and t...

Embodiment 2

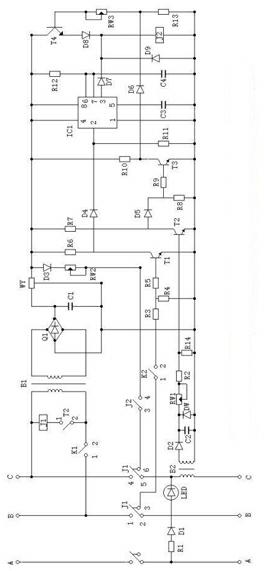

[0026] like figure 2 As shown: the configuration of the three-phase electric load remote automatic control power supply device described in this embodiment is basically the same as that of the single-phase electric load remote automatic control power supply device described in Embodiment 1. The identification circuit is composed of a power supply, power-off execution control circuit and an on-load continuous power supply identification control circuit. The external line also refers to the line between the front end of the power control switch and the load terminal, and the power control switch refers to the switch knife. The main difference is: in the working power circuit of the whole machine, the AC power is sent to the primary of the transformer B1 through the switch K, and after the voltage is stepped down by the transformer, it is sent to the bridge stack Q1 for rectification to obtain a pulsed DC voltage, which is passed through the filter capacitor C1 After filtering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com