Mobile waste cigarette treating machine

A technology of waste cigarette sticks and processing machines, which is applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve the problems of cigarette production cycle impact, investment, large structure, inconvenient, and flexible, and achieve automatic, parameterized, and convenient processing The effect of classification unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

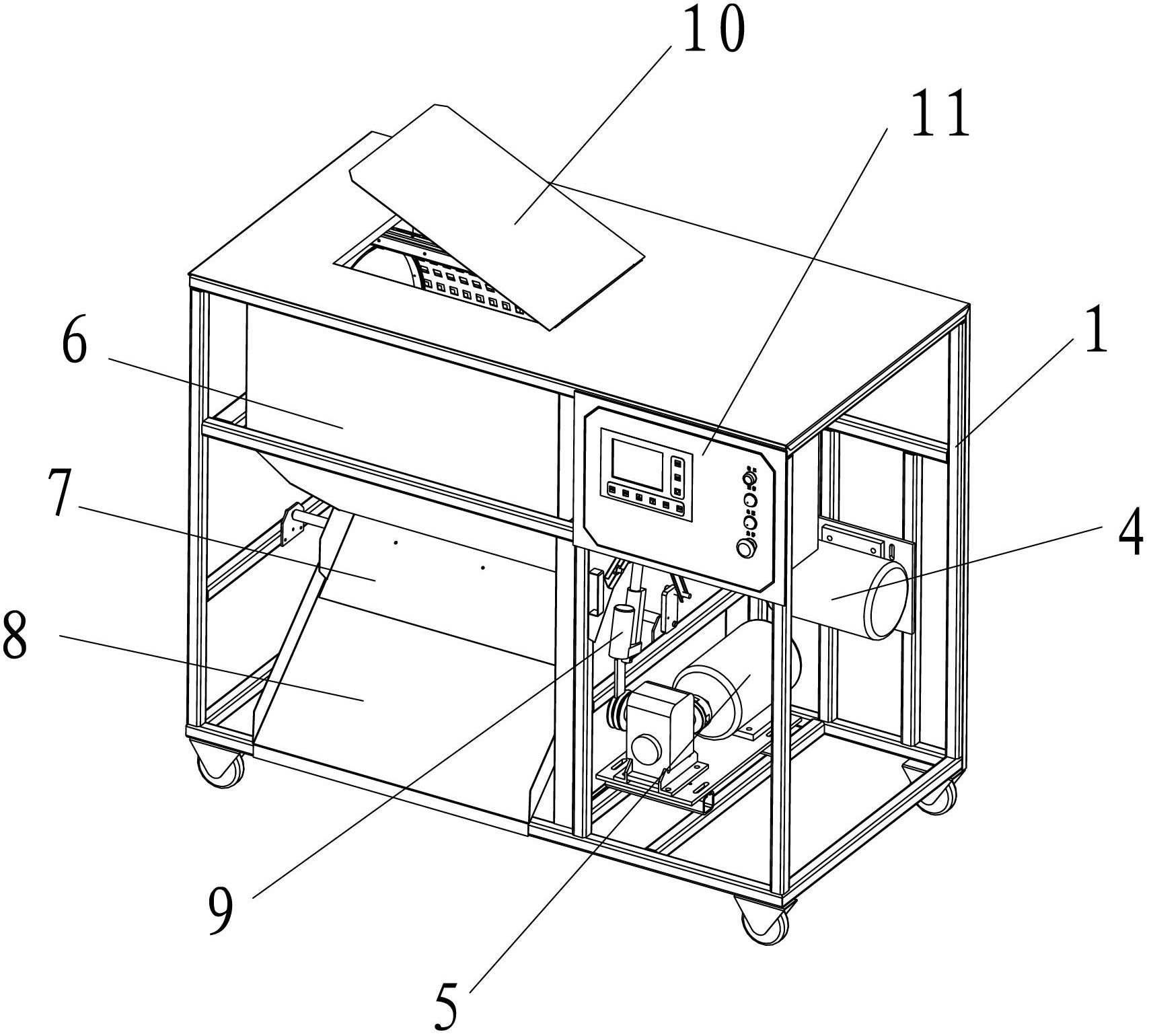

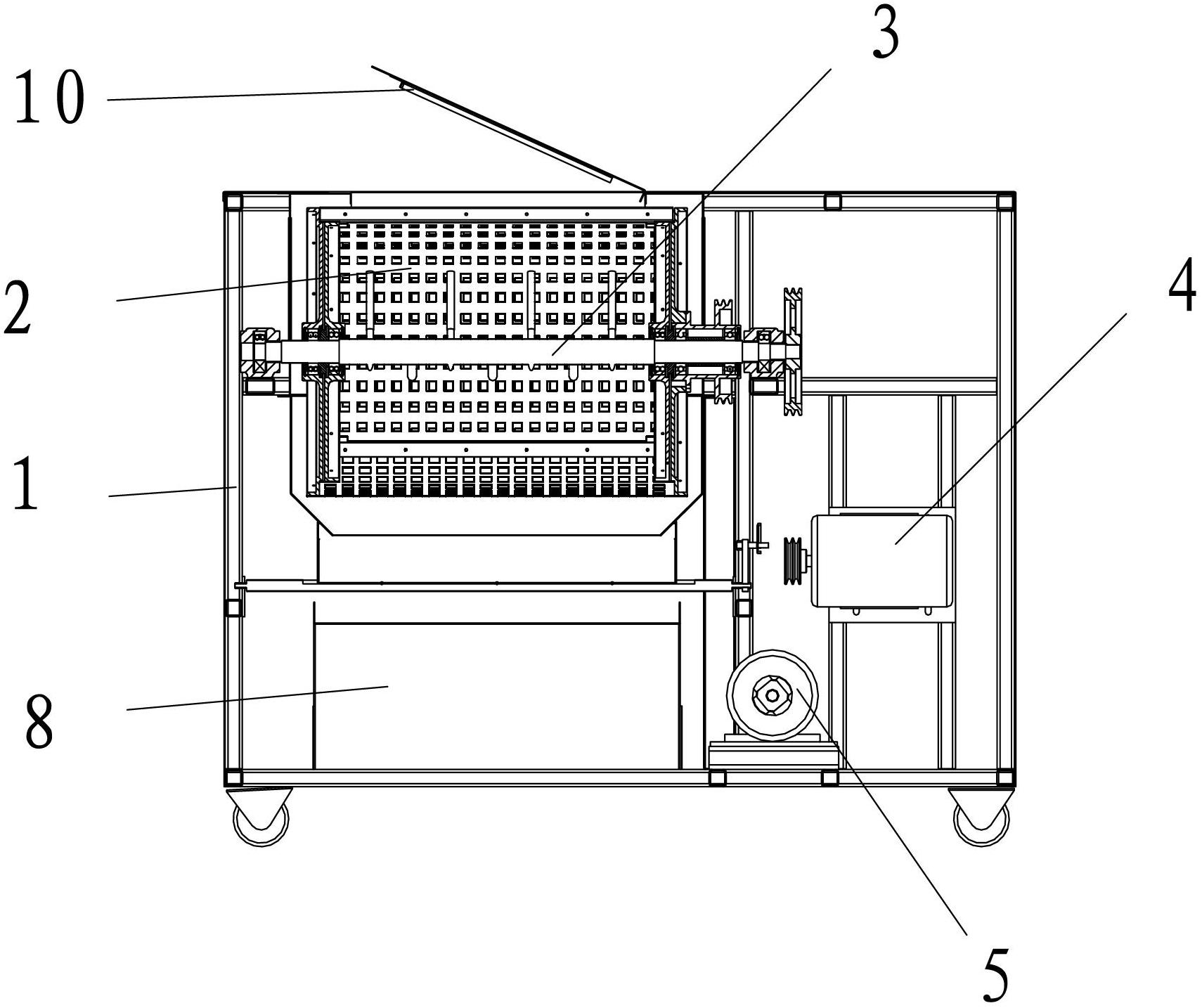

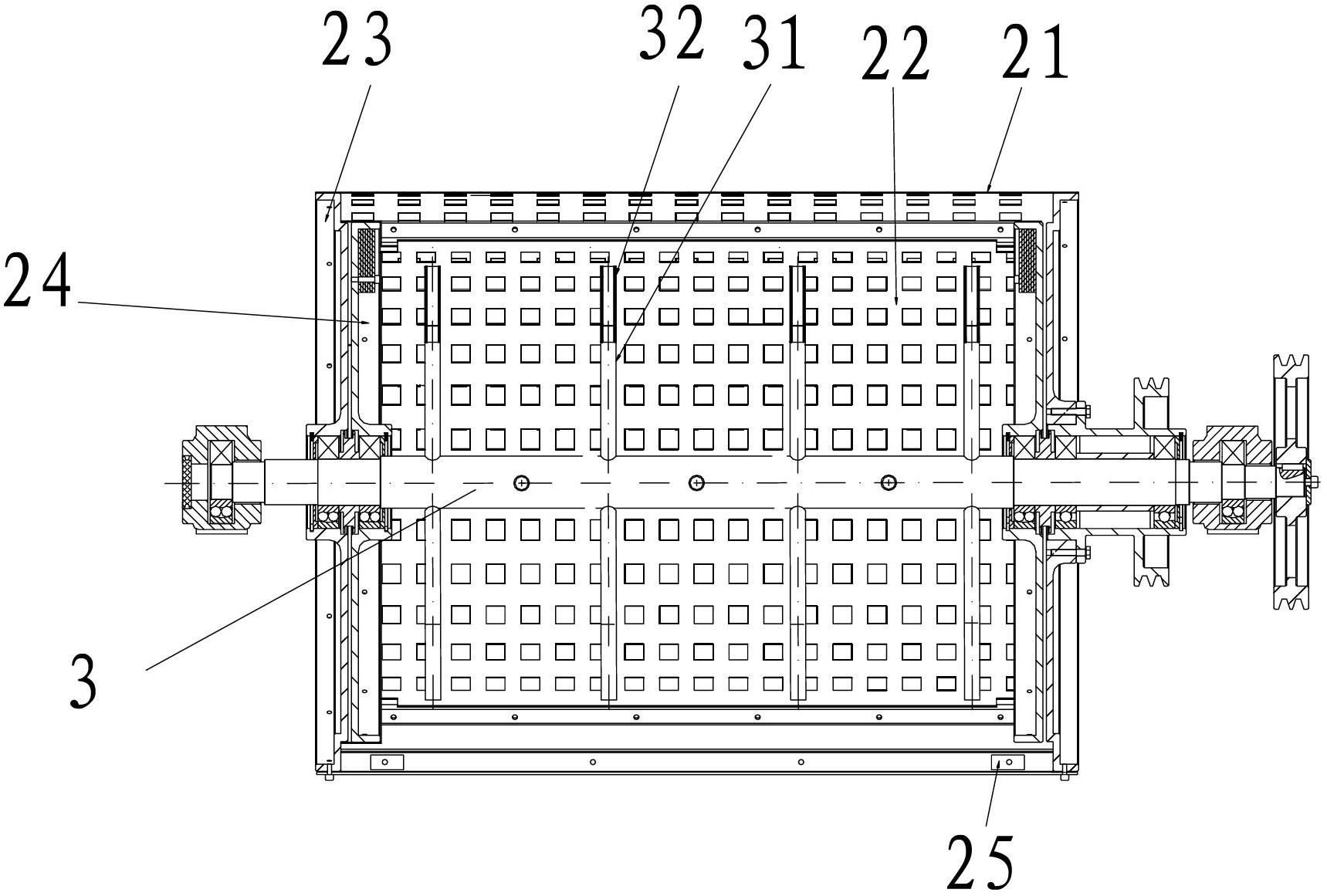

[0030] A mobile waste cigarette processing machine includes a frame 1, a sieve cylinder 2, a silo 6, a discharge plate 7, a diversion slope 8, an electric push rod 9, a central stirring roller shaft 3, a stirring roller shaft motor 4, and a sieve cylinder The motor 5, a belt wheel, a frequency converter, and a single-chip microcomputer program control board are composed. The upper end of the frame 1 is provided with a feed inlet. Outer sieve cylinder 21, inner sieve cylinder 22, outer cylinder end plate 23, inner cylinder end plate 24, central stirring roller shaft 3, and stirring rod form the core of processing and screening---the sieve cylinder assembly. The sieve hole diameter of the sieve cylinder is 6-7mm, and the outer sieve cylinder 21 and the inner sieve cylinder 22 are incomplete (the outer sieve cylinder 21 has a 3 / 4 circumference of the cylinder wall, and the inner sieve cylinder 22 has a 1 / 4 circumference of the cylinder wall, The missing 1 / 4 wall of the outer scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com