Nanometer hemostatic material product and preparation method thereof

A hemostatic material and nanotechnology, applied in textiles and papermaking, medical science, fiber processing, etc., can solve the problems of unsatisfactory production or use process, tissue damage, slow hemostasis, etc., to promote normal growth, promote repair, promote effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

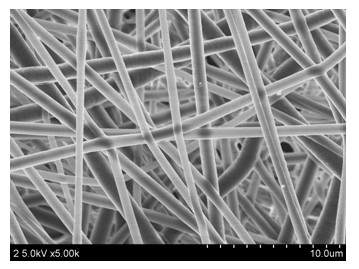

[0022] Example 1: Prepare a nanofiber membrane with a blood carbon content of 5 wt%, and the corresponding proportions of the polymer solution to be prepared: blood carbon content is 0.25 wt%, polylactic acid is 4.75%, and organic solvent is 95 wt%. The specific operation is: weigh 0.627g polylactic acid PLLA and 0.033g blood residue carbon with a balance, dissolve them in 7ml chloroform and 3.5ml acetone, and seal the bottle mouth to prevent solvent volatilization. Stir on a magnetic stirrer for 5 hours until completely dissolved to obtain an electrospinning polymer solution. Electrospinning was performed on the obtained solution, the applied voltage was 20KV, the receiving distance was 12cm, the spinning speed was 0.7ml / h, and the diameter of the spinneret was 0.8mm. The diameter of the obtained nanofiber is between 300nm and 900nm, and the filaments are relatively uniform.

Embodiment 2

[0023] Example 2: Preparation of a nanofiber membrane with a blood carbon content of 10 wt%, corresponding to the proportion of the polymer solution to be prepared: blood carbon content is 0.5 wt%, polylactic acid is 4.5%, and organic solvent is 95 wt%. The specific operation is as follows: weigh 0.594g polylactic acid PLLA and 0.066g blood residue charcoal with a balance, dissolve them in 7ml chloroform and 3.5ml acetone, and seal the bottle mouth to prevent solvent volatilization. Stir on a magnetic stirrer for 5 hours until complete dissolution. That is, the electrospinning polymer solution is obtained. Electrospinning was performed on the obtained solution, the applied voltage was 20KV, the receiving distance was 12cm, the spinning speed was 0.7ml / h, and the diameter of the spinneret was 0.8mm. The diameter of the obtained nanofiber is between 350nm and 1000nm, and the filament formation is relatively uniform.

Embodiment 3

[0024]Example 3: Prepare a nanofiber membrane with a blood carbon content of 15 wt%, and the corresponding ratio of the polymer solution to be prepared: blood carbon is 0.75 wt%, polylactic acid is 4.25 wt%, and organic solvent is 95 wt% . The specific operation is: weigh 0.561g polylactic acid PLLA and 0.099g blood residue carbon with a balance, dissolve them in 7ml chloroform and 3.5ml acetone, and seal the bottle mouth to prevent solvent volatilization. Stir on a magnetic stirrer for 5 hours until complete dissolution. That is, the electrospinning polymer solution is obtained. Electrospinning was performed on the obtained solution, the applied voltage was 20KV, the receiving distance was 12cm, the spinning speed was 0.7ml / h, and the diameter of the spinneret was 0.8mm. The diameter of the obtained nanofiber is between 500nm and 1100nm, which is increased compared with the above two implementations.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap