Microelectrode array architecture

A micro-electrode array and micro-electrode technology, applied in electrical digital data processing, laboratory containers, instruments, etc., can solve the problems of difficulty in implementing and lacking hierarchical design methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

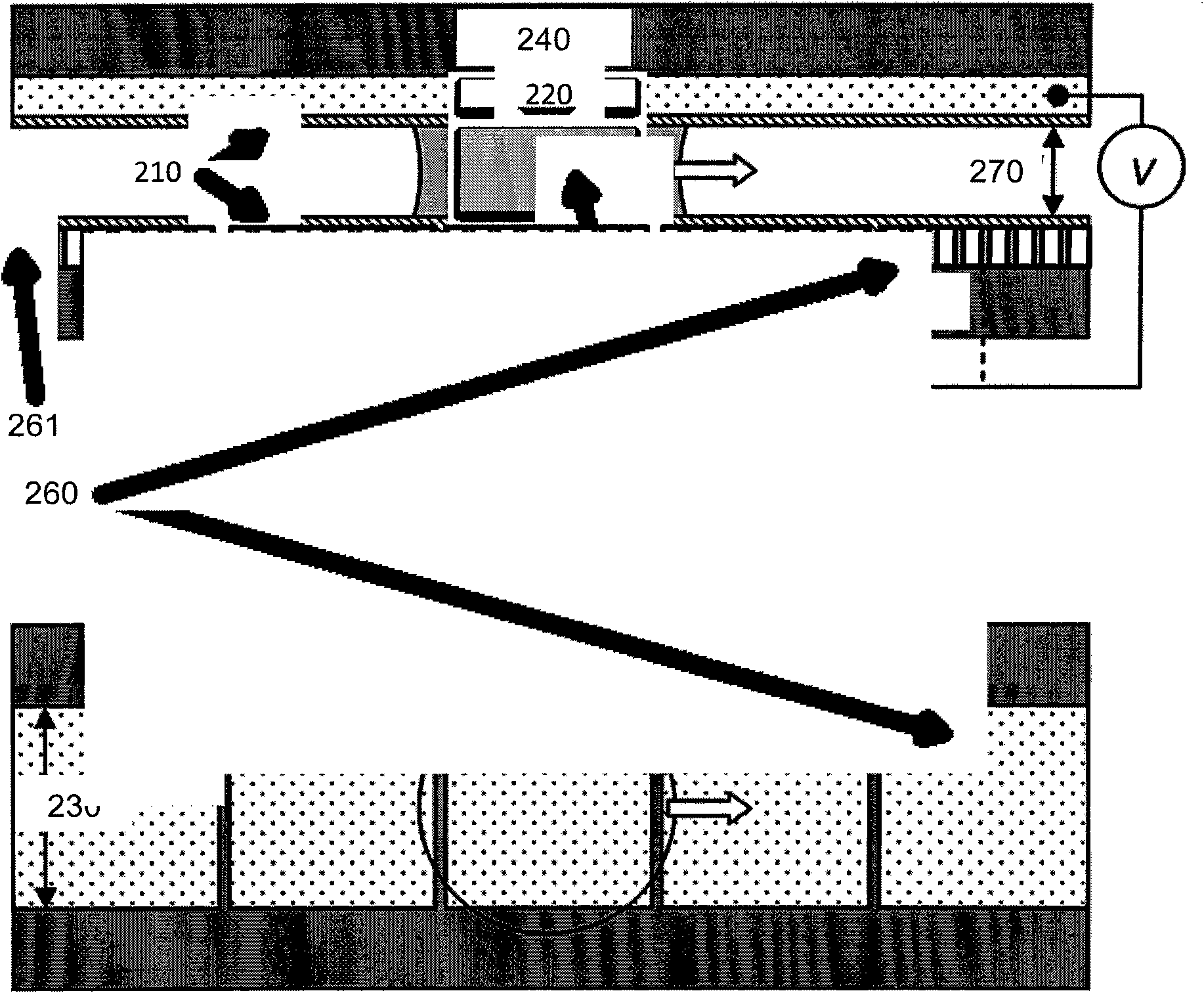

[0096] The microelectrode array structure is applicable to other digital microfluidics technologies such as dielectrophoresis (DEP) based technologies, but for discussion purposes below, various embodiments of the invention will be described using EWOD technology.

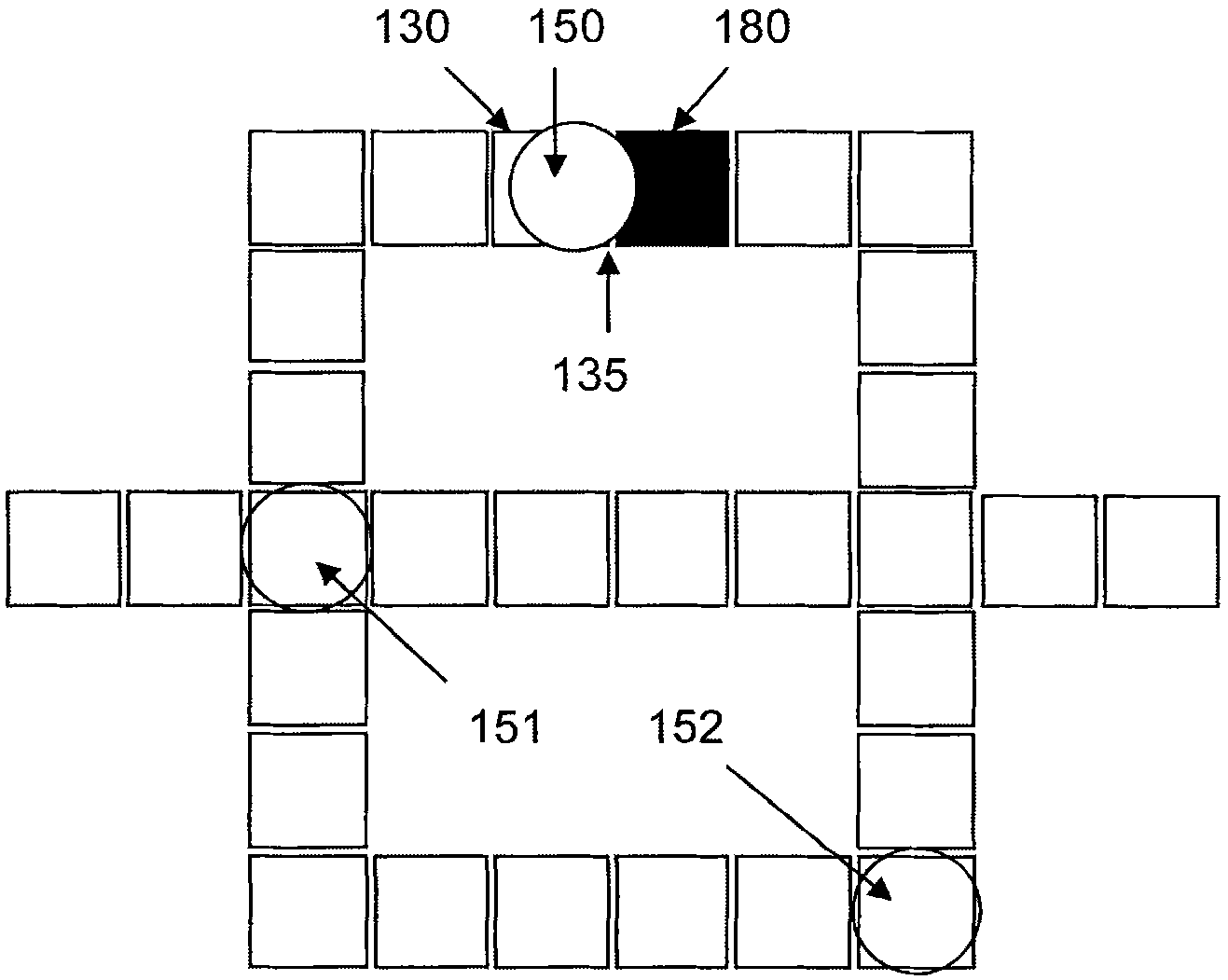

[0097] EWOD-based devices are commonly used to manipulate droplets by exciting them with interfacial tension gradients across the gap between adjacent electrodes. The design of the electrodes includes the desired shape, size of each electrode and the gap between each two electrodes. In droplet manipulation based on EWOD-based LOC layout design, the droplet path is usually constructed by multiple electrodes connecting different regions of the design.

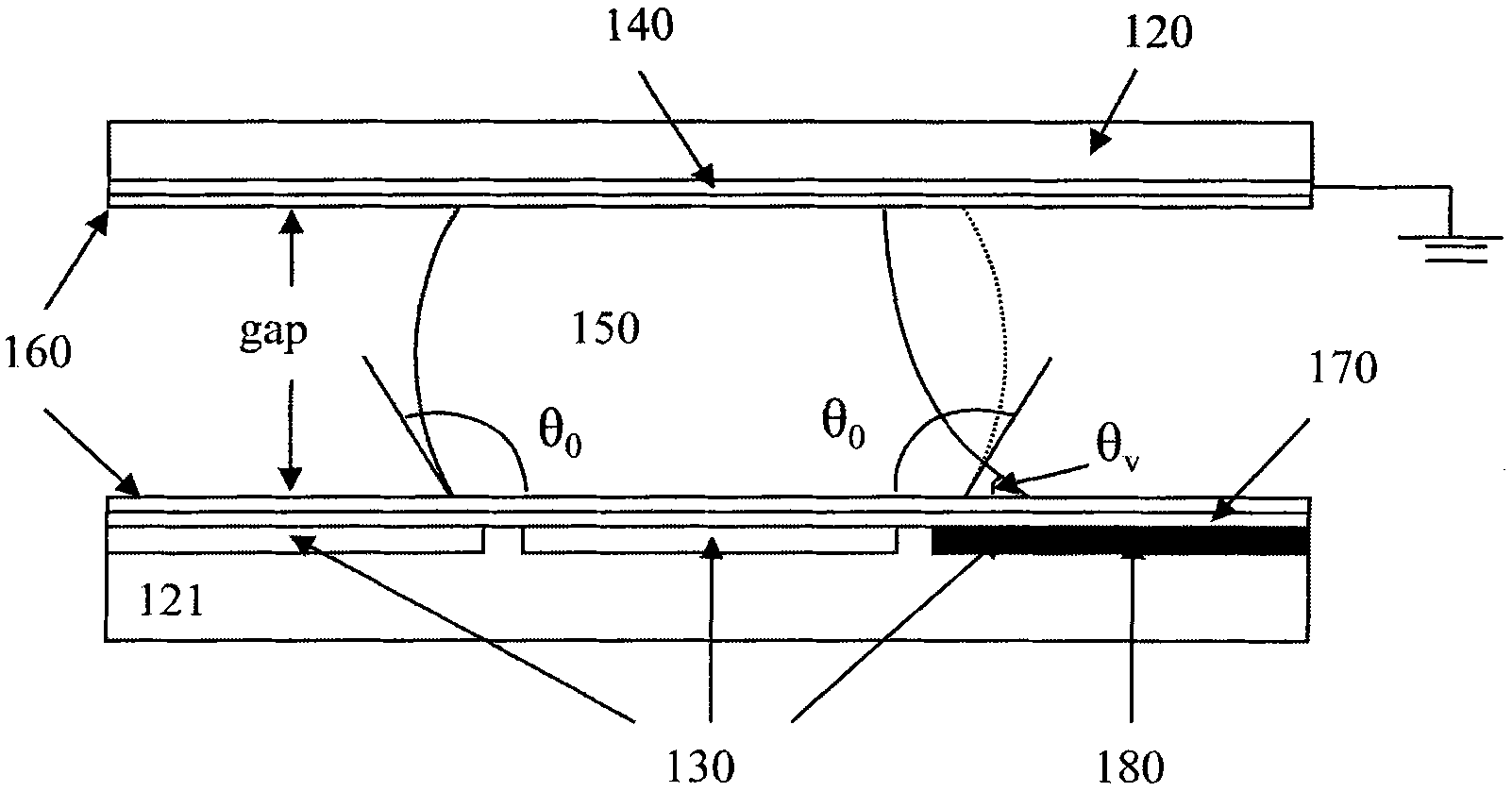

[0098] exist Figure 1AA conventional electrowetting microactuator structure is shown in (shown on a smaller scale for illustrative purposes only). The EWOD-based digital microfluidic device includes two glass plates 120 and 121 parallel to each other. The bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com