Lead bar production equipment

A technology for producing equipment and lead bars, which is applied in the field of environment-friendly lead bar production equipment, and can solve problems such as environmental damage, failure to meet energy conservation and environmental protection, and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

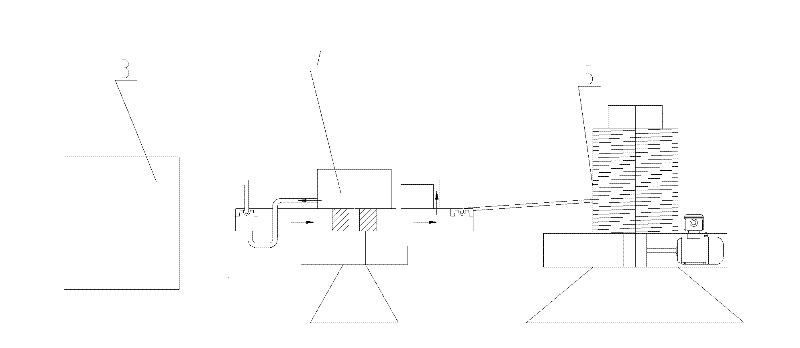

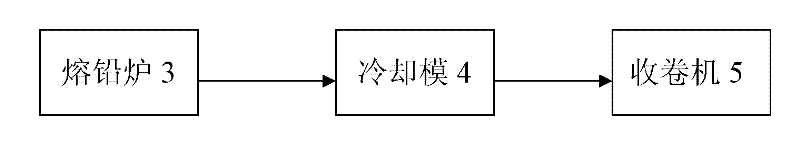

[0023] Such as figure 1 , 2 Shown, a kind of lead bar production equipment, it comprises cooling mold 4 and winding machine 5, described cooling mold 4 is provided with lead liquid inlet 9 and lead bar outlet 10, and the lead liquid inlet 9 of cooling mold 4 is positioned at molten lead Below the lead liquid outlet of the furnace 3, the lead strip outlet 10 of the cooling mold 4 outputs the lead strip to the winder 5 for winding; the section of the lead strip is circular, rectangular, triangular or other irregular shapes.

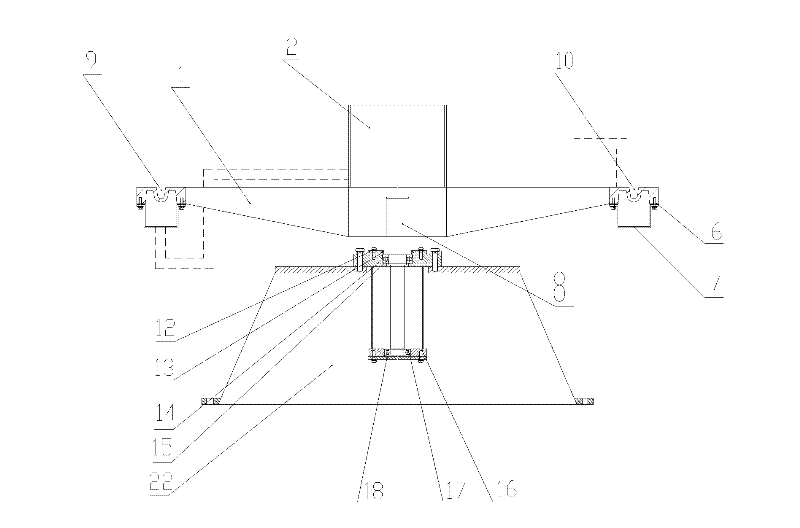

[0024] Such as image 3 , 4 As shown, the cooling mold 4 includes a turntable type cooling tank 1, a water storage bucket 2, a water jacket 7, a main shaft 8, a warping knife 11 and a base 22; the base 22 is equipped with a rotatable main shaft 8, and on the other end of the main shaft The turntable type cooling tank 1 is set, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com