In-mold injection molding method and in-mold injection molding mold

A technology of forming molds and in-mold injection molding, applied in coating and other directions, can solve problems such as poor hemming effect and complicated procedures, and achieve the effect of improving production efficiency and shortening production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

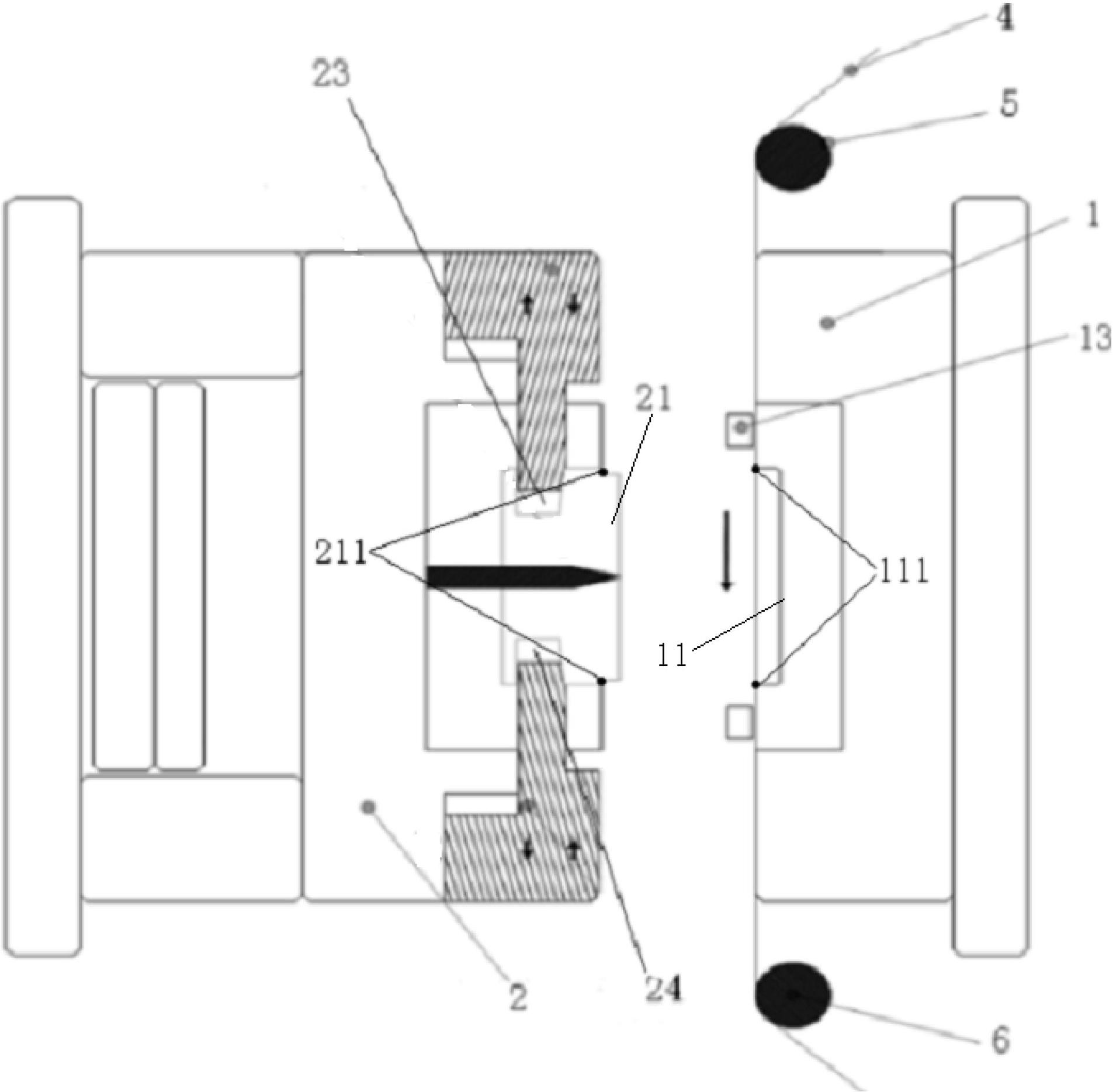

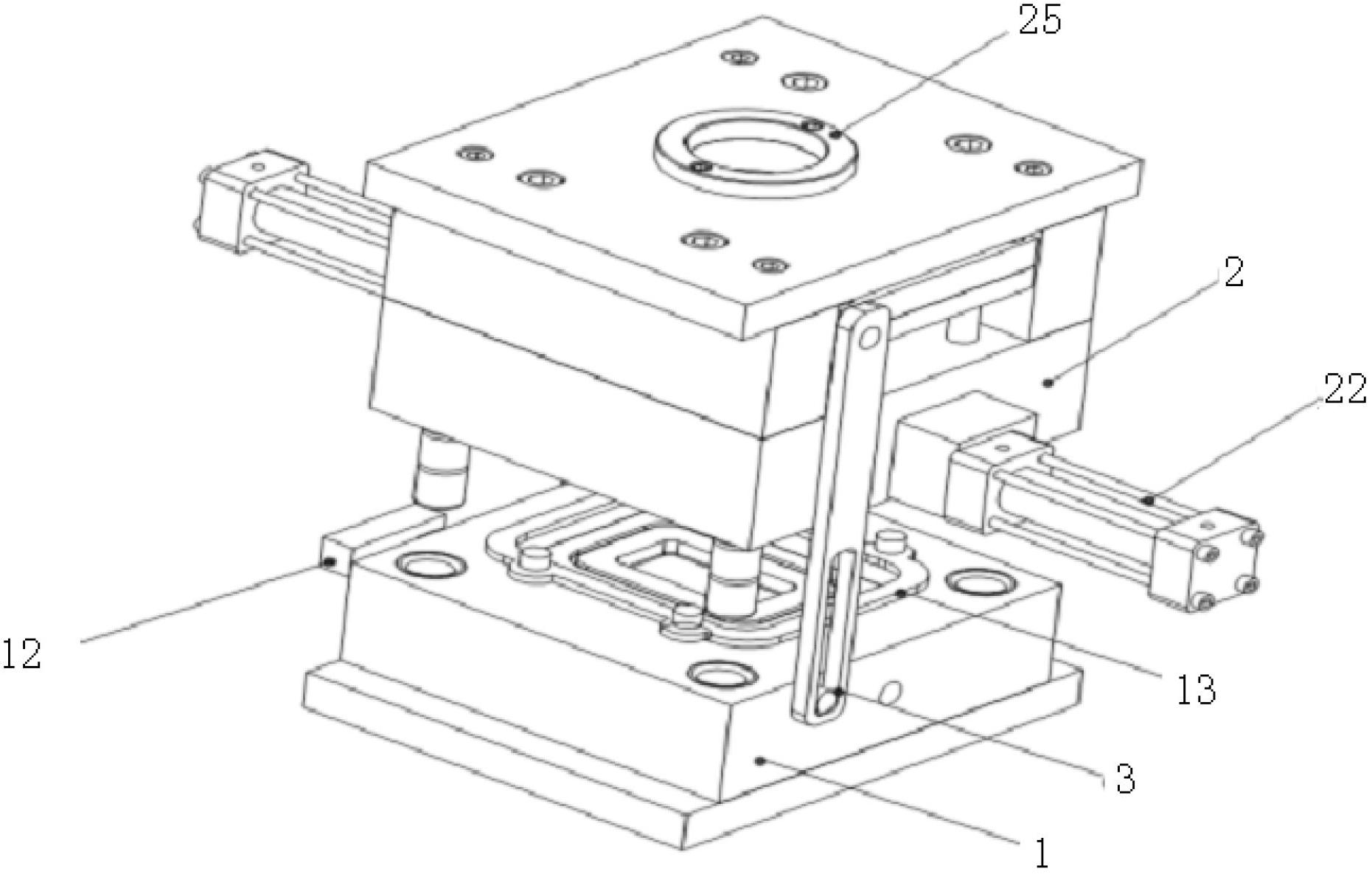

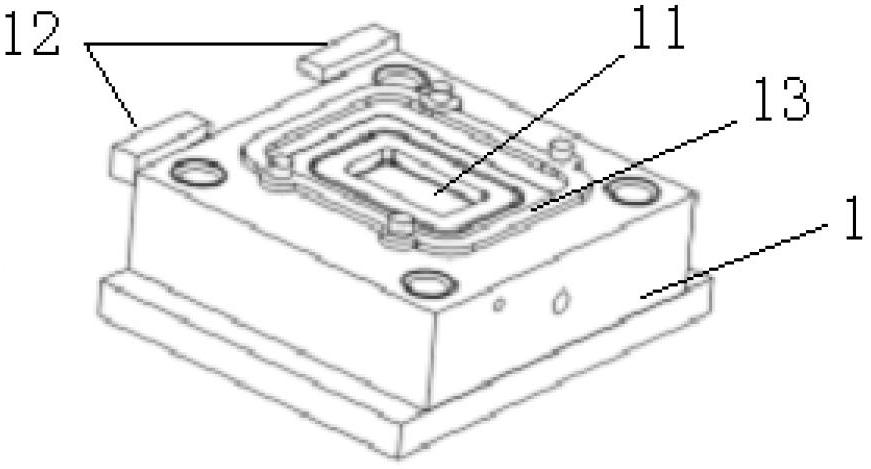

[0034] Such as Figures 1 to 7 Shown: the in-mold injection molding mold comprises a movable mold 1, a fixed mold 2, a concave mold cavity 11 arranged on the movable mold 1 and a punch 21 arranged on the fixed mold 2, and the fixed mold 2 is also provided with The first slide block 23 and the second slide block 24 that advance and retreat are controlled by the oil cylinder 22, and the first slide block 23 and the second slide block 24 are fixedly connected to the two ends of the punch 21 respectively; The corresponding position of the edge of concave mold cavity 11 is provided with the first knife-edge 211 along the periphery; The second knife-edge 111 corresponding to the first knife-edge 211 is also provided on the described concave m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com