Composite axle box positioning device and processing and assembling method thereof

A technology of positioning device and assembly method, which is applied in axle box installation, metal processing, metal processing equipment, etc., can solve the problems of tight space under the vehicle, poor access to maintenance and inspection, etc., and achieves increased space under the vehicle, easy installation and The effect of disassembly and reduction of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

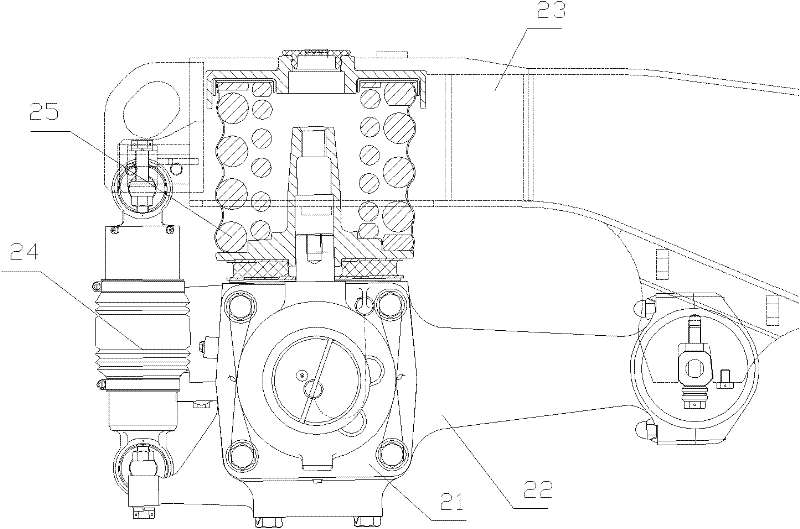

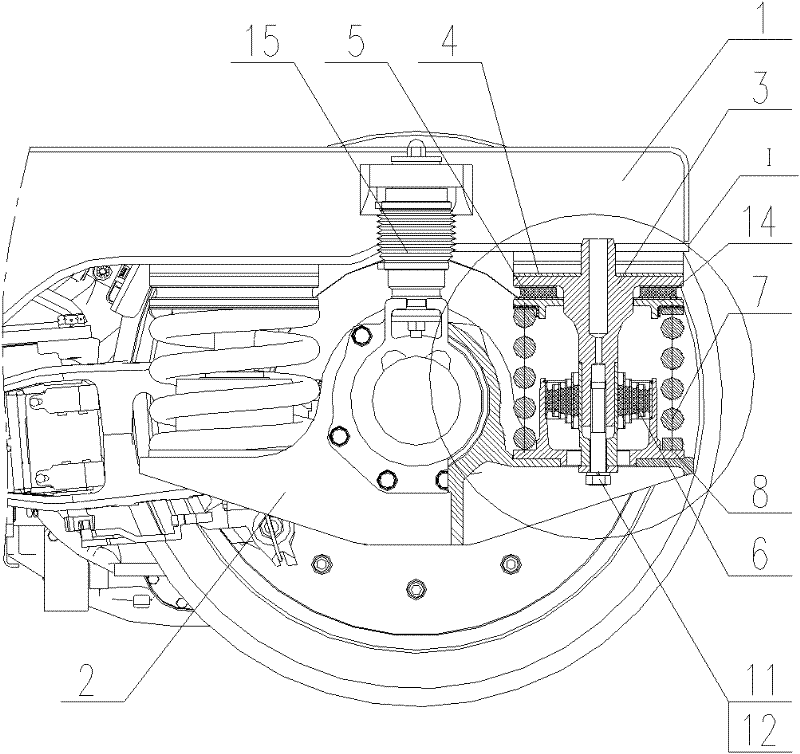

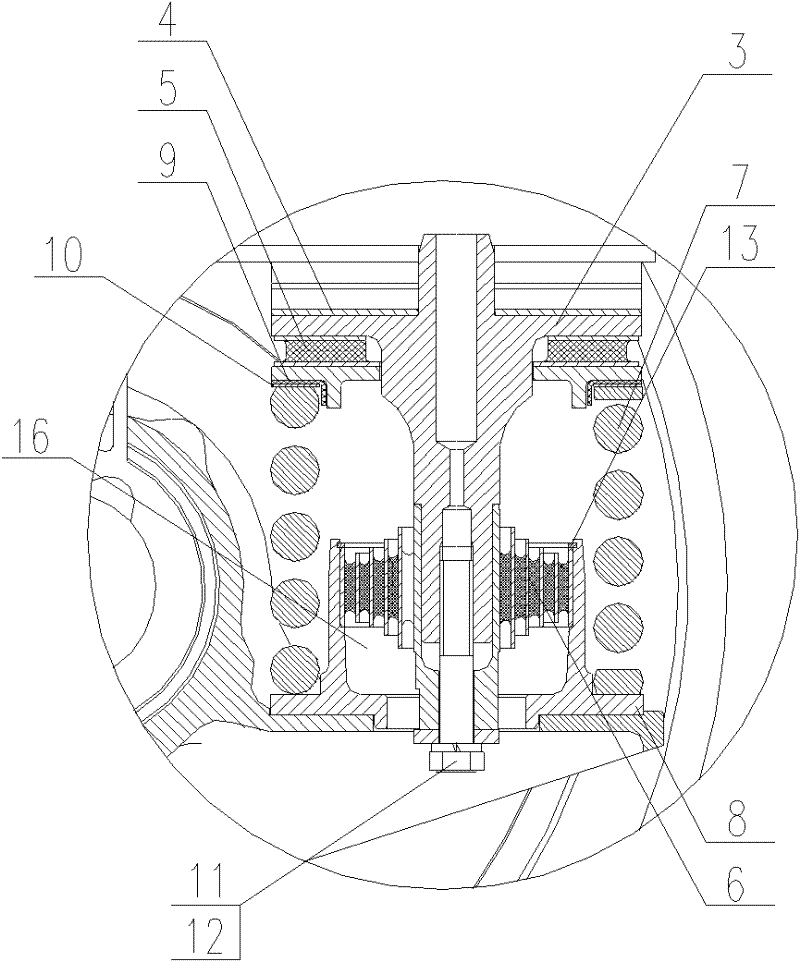

[0043] Example 1, such as figure 2 with image 3 As shown, the described composite axle box positioning device mainly includes:

[0044] Vertically connected to the positioning guide post 3 of the frame 1 through the positioning bolt 11, and an adjustment pad 4 is lined between the positioning guide post 3 and the frame 1;

[0045] The lower splint 8 and the upper splint 14 arranged on the mounting seat of the axle box body 2;

[0046] A steel spring 7 is clamped between the lower splint 8 and the upper splint 14, and an insulating backing plate 9 and a spacer 10 are lined between the upper splint 14 and the steel spring 7;

[0047] The lower splint 8 is provided with a groove 16 surrounding the positioning guide post 3, and a rubber spring 6 is set on the positioning guide post 3 inside the groove 16;

[0048] At the upper end of the groove 16, a snap ring 13 for limiting the rubber spring 6 is press-fitted.

[0049] An anti-vibration rubber 5 is lined between the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com