Device for manufacturing plating layer of metal multilayer film

A multi-layer film and coating technology, applied in the direction of electrolysis process and electrolysis components, can solve the problems of difficult operation and complex structure, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

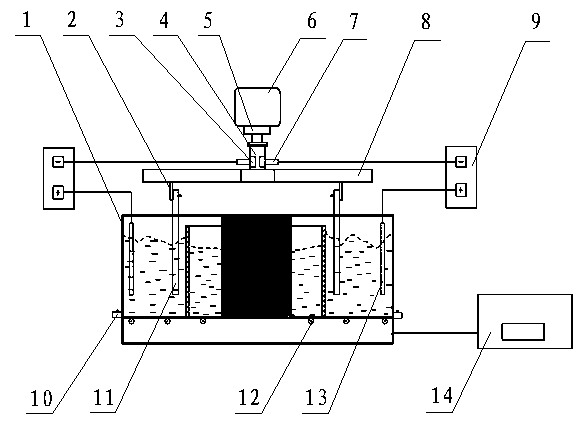

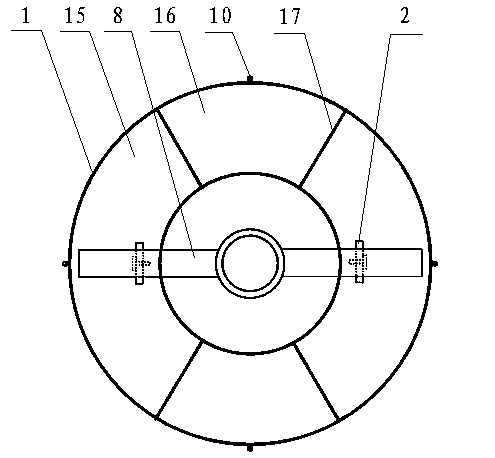

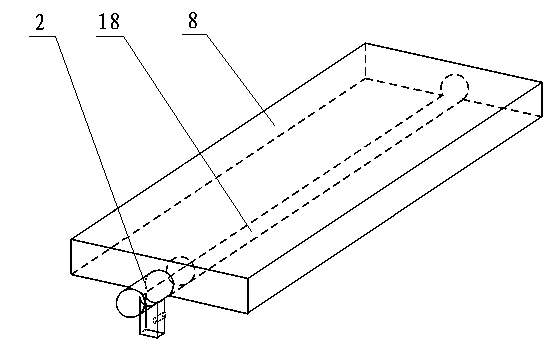

[0023] The present invention prepares the embodiment of the device of metal multilayer coating: as Figure 1-3 As shown, it includes a ring groove 1, a rotating mechanism, and two power sources 9. The device uses electrodeposition to prepare metal multilayer films. The two power sources 9 are used to provide currents of different sizes. Of course, different types of power sources can also be used according to actual needs. Current, such as direct current and pulse current. The material of the annular groove 1 is insulating materials such as glass and plastics, and four partitions 17 arranged at intervals in the circumferential direction are connected between the inner and outer groove walls of the annular groove 1, so that the annular groove 1 is divided into four fan-shaped grooves, The size of the two relative fan-shaped tanks is the same. When in use, different electrolytes are respectively filled in the two relative fan-shaped tanks. Distilled water is filled respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com