Cushioning type ball winding rod device

A ball bat and stick body technology, applied in the direction of processing textile material rollers and textile material carriers, etc., can solve problems such as damage to the ground and cushioning pads, pits on the ground, and damage to the bat wrapped around the ball. Buffering effect, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

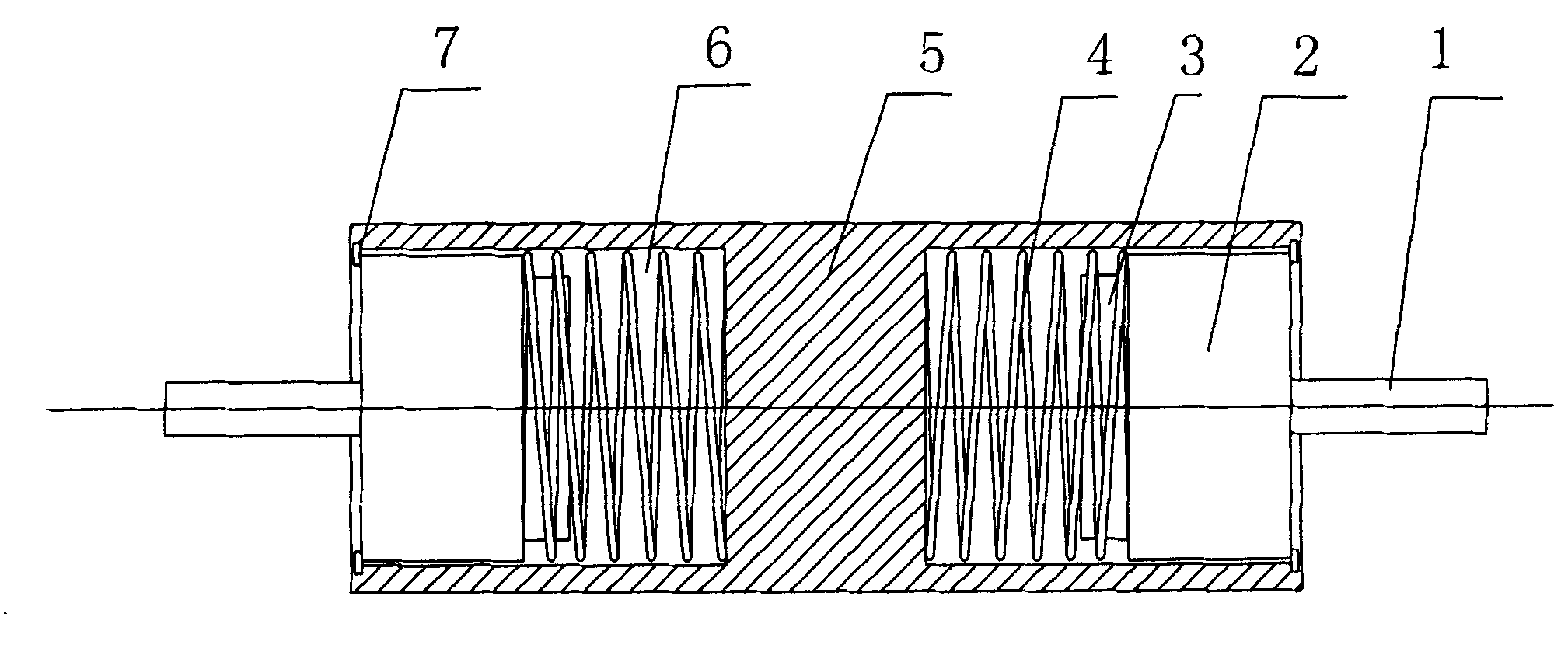

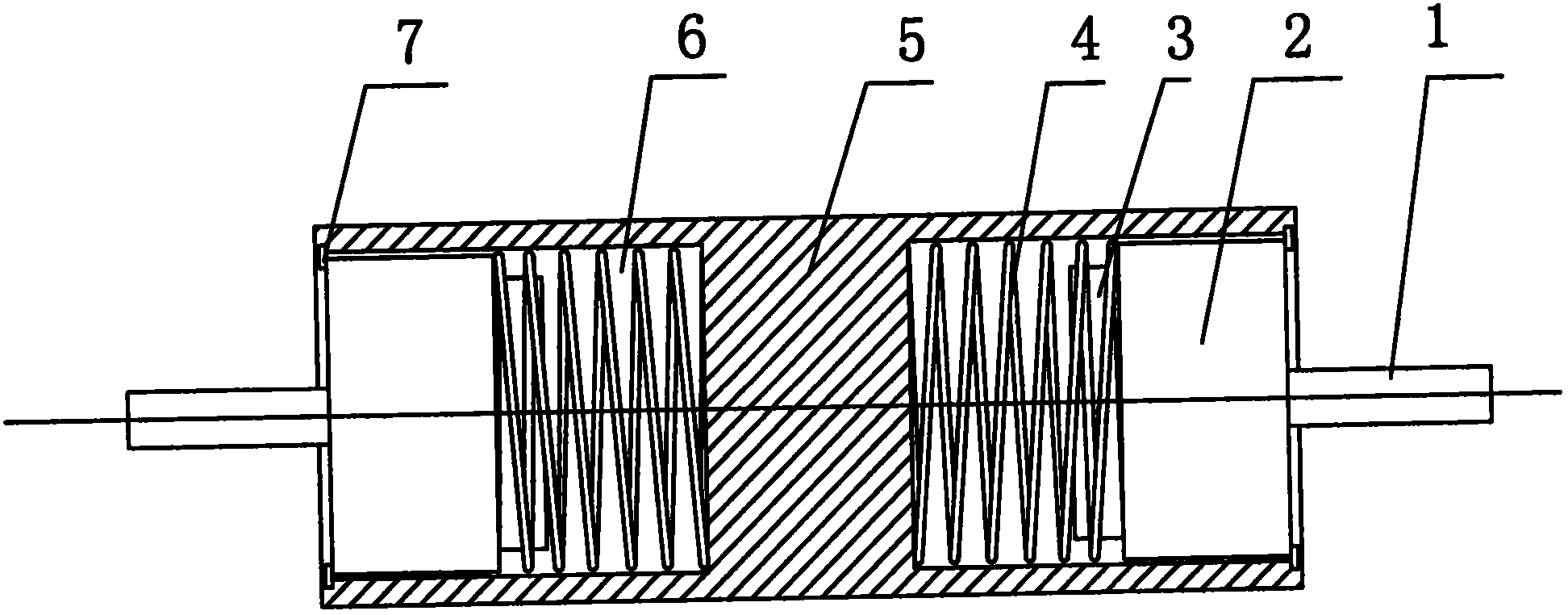

[0015] like figure 2 As shown, the processing process is as follows:

[0016] 1) Processing of the ball-wound bat body: processing an iron cylinder with a height of 50 cm and a diameter of 16 cm, and hollowing out a cylindrical blind hole with a diameter of 8 cm and a depth of 15 cm at both ends;

[0017] 2) Machining the spring slot: at 3 cm of the inner circle of the blind hole port, machine a ring spring slot with a depth of 0.5-0.7 cm

[0018] 3) Processing of the piston: the middle diameter of the piston is 15.7 cm, the diameter of the boss is 10 cm, the diameter of the shaft head is 6 cm, and the spring is installed at one end of the boss;

[0019] 4) Install the end of the piston connected to the spring into the cylindrical blind holes at both ends of the rod body, and use a spring clip to fix the shaft head. The diameter of the spring clip should be larger than the inner diameter of the cylindrical groove to achieve a better fixing effect. Install Then there is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com