Axial double-floating structure of scroll compressor

A scroll compressor and floating structure technology, applied in the field of compressors, can solve the problems of increased scroll leakage, increased internal leakage of the compressor, poor processing economy, etc., to reduce clearance, reduce matching accuracy, improve The effect of processing economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

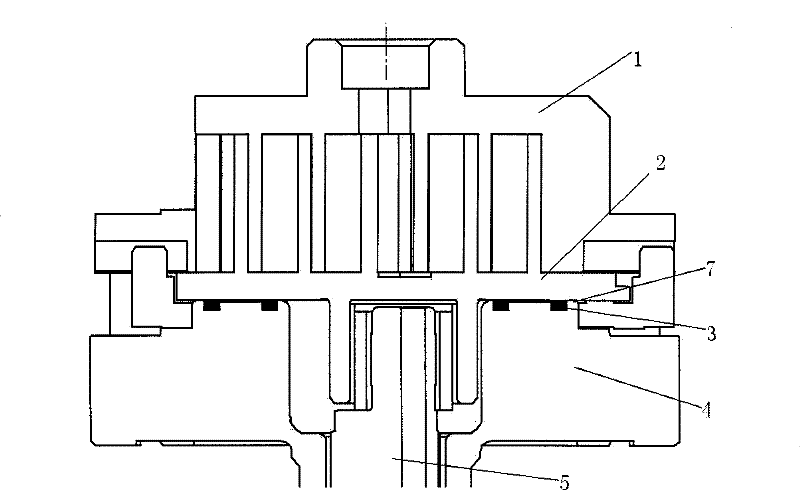

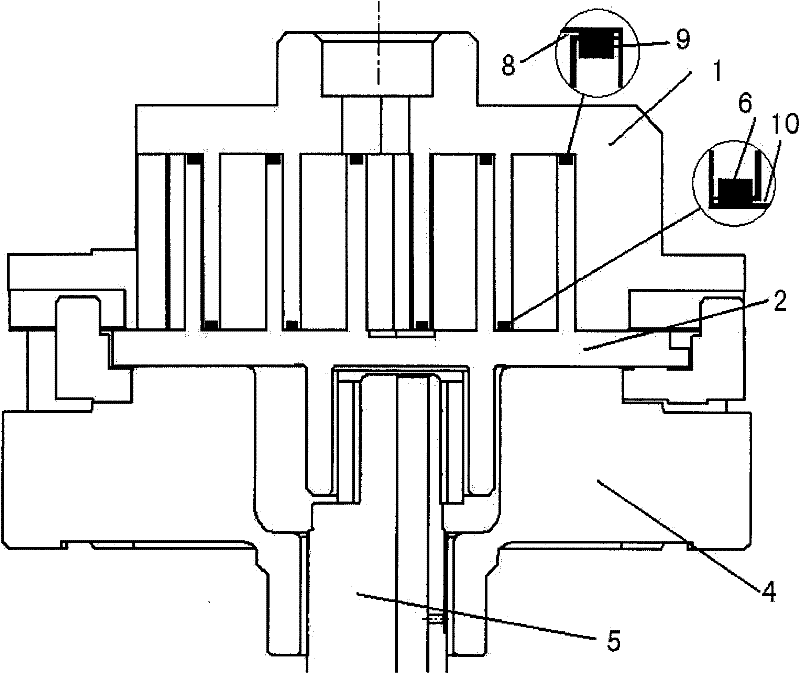

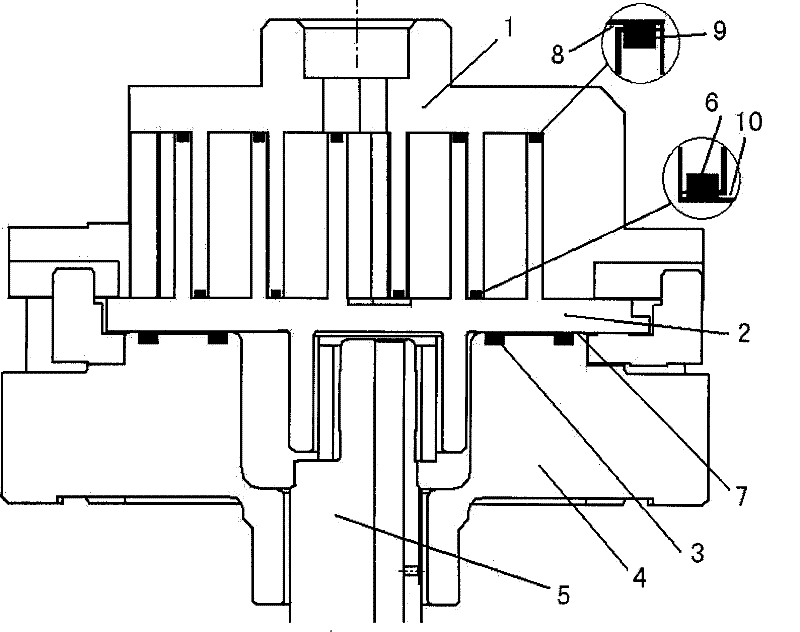

[0014] Such as image 3 As shown, a scroll compressor has an axial double-floating structure, including a fixed scroll 1, a movable scroll 2, a back pressure chamber seal ring 3, a bracket 4, a crankshaft 5, an addendum seal ring 6, and an addendum seal ring 9 , the fixed scroll 1 and the movable scroll 2 are set on the bracket 4, the fixed scroll 1 is located above the movable scroll 2, the teeth of the fixed scroll 1 face down and the teeth of the movable scroll 2 face upward, and the static scroll 1 The tooth top of the scroll 1 is provided with a tooth top seal ring 6, the tooth top of the movable scroll 2 is provided with a tooth top seal ring 9, and there is a small gap between the tooth top of the movable scroll 2 and the tooth bottom of the fixed scroll 1. Gap 8; There is a small gap 10 between the tooth top of the fixed scroll 1 and the tooth bottom of the movable scroll 2. The movable scroll 2 is arranged on the support 4 , a floating gap 7 is formed between the mov...

Embodiment 2

[0018] see image 3 , a scroll compressor with an axial double floating structure, the scroll compressor adopts the axial floating structure of the fixed scroll, and at the same time, seal grooves are set on the tooth tops of the movable and fixed scrolls, and the sealing rings are put in, and the fixed and movable scrolls The two fits of the tooth top and the bottom of the tooth are clearance fits, and the clearance is greater than the elongation of the thermal expansion of the scroll teeth, and smaller than that of the non-floating, movable scroll and fixed scroll tooth top sealing ring structure. The fit clearance of the bottom of the tooth, the elongation of the thermal expansion of the scroll tooth is 30 microns, the non-floating, the top of the movable scroll and the bottom of the fixed scroll with the structure of the tooth top seal ring of the movable scroll and the fixed scroll The fit clearance is 150 microns, that is, the fit clearance is greater than 30 microns and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com