New Structure of Mechanical Seal for Diesel Locomotive Cooling Water Pump

A technology for cooling water pumps and mechanical seals, applied in engine cooling, mechanical equipment, machines/engines, etc., can solve the problems of high-power diesel locomotives without major breakthroughs, water pump leakage problems not effectively solved, and locomotive outages, etc. Achieve the effects of simple structure, reduced water leakage frequency and high sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

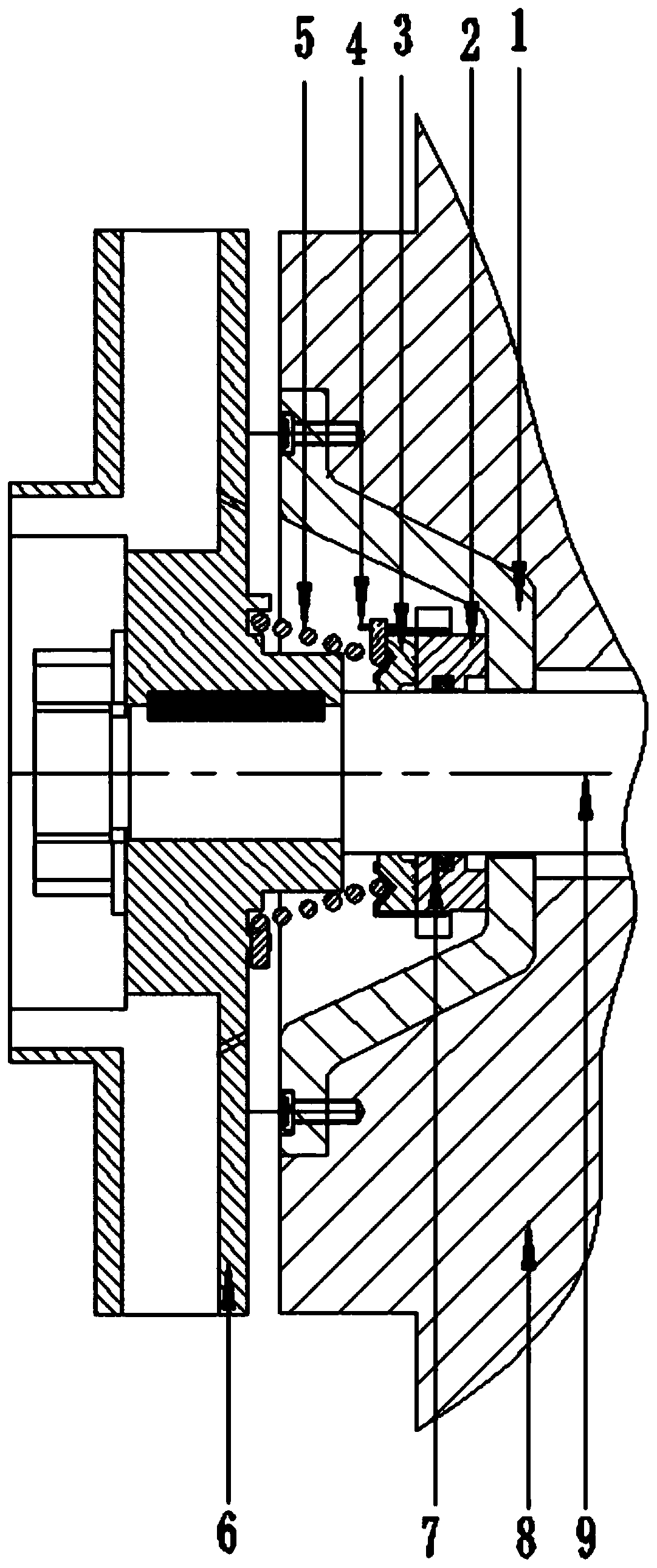

[0015] Attached below Figure 1-4 The specific embodiment of the present invention will be further described.

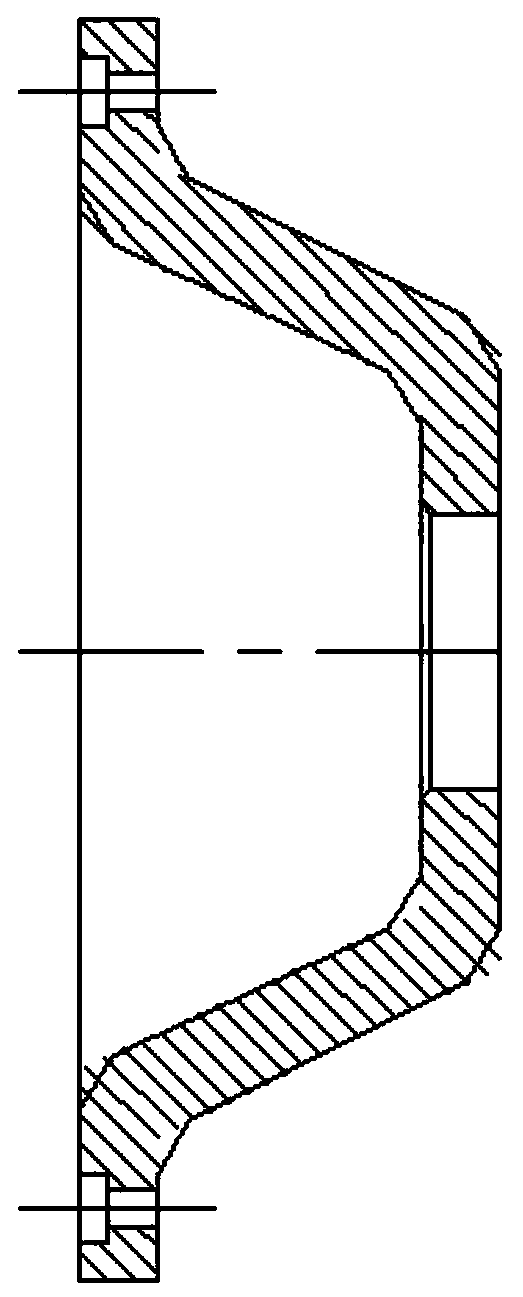

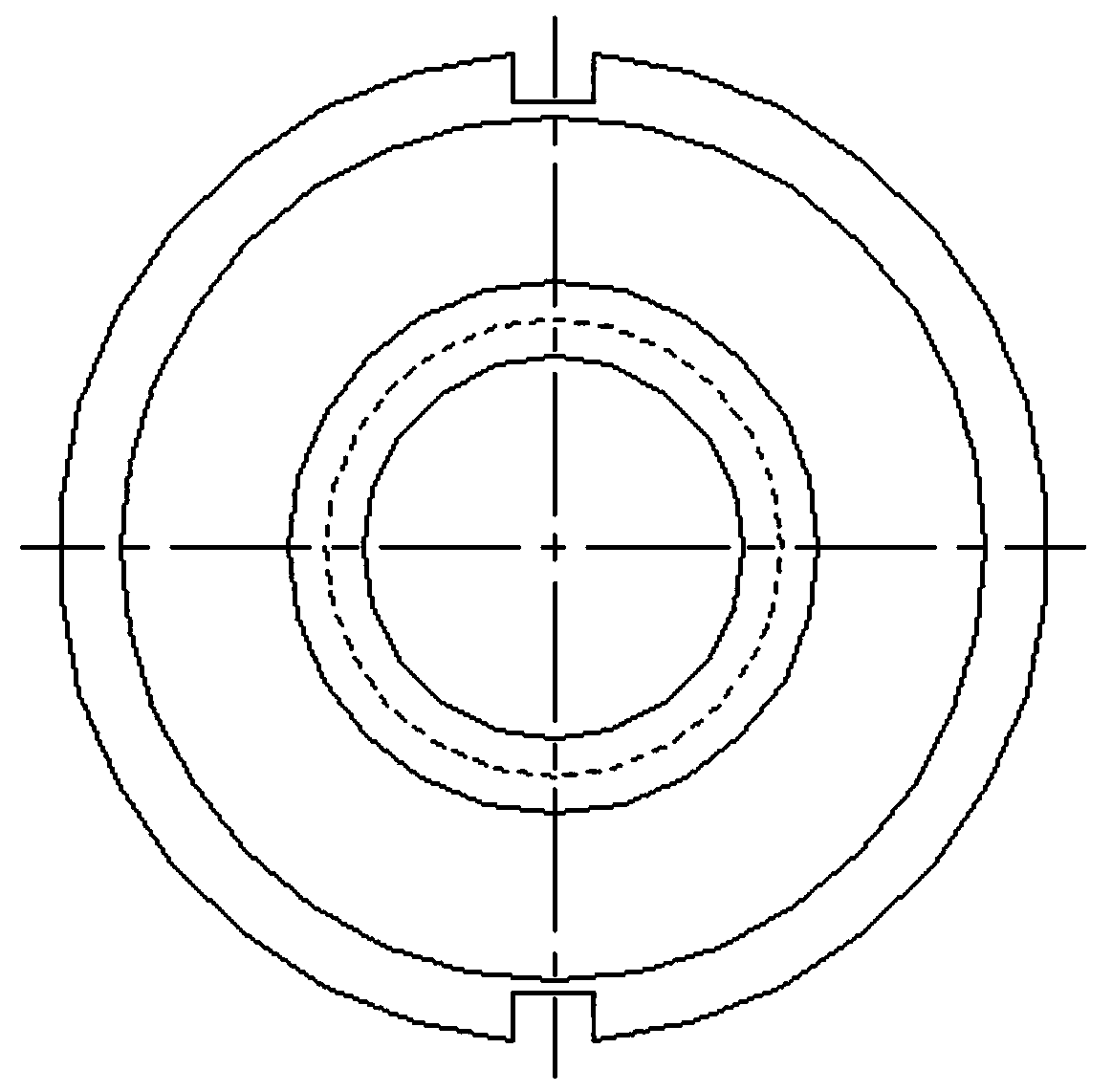

[0016] The new mechanical seal structure of the diesel locomotive cooling water pump includes the impeller 6, the pump body 8 and the shaft 9. The shaft 9 is installed in the pump body 8, and the impeller 6 is installed at the end of the shaft 9. Due to the good stability of the tower spring, we adopt The tower spring, the inner straight platform of the impeller 6 is fixedly connected with the large end of the tower spring 5, the small end of the tower spring 5 is fixedly connected with one side of the convex push frame 4, and the other side of the convex push frame 4 is There are two bosses in the axial direction of the diameter, and the two bosses are stuck in the straight groove of the outer diameter of the dynamic seal ring 2. The concave shaft seal 3 is installed between the convex push frame 4 and the dynamic seal ring 2, and the concave shaft seal 3 and The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com