Catalysts and method for producing recycled polyester

A catalyst and recycling technology, applied in the field of diethylene, can solve the problems of no reported PET chemical recycling method, etc., and achieve the effect of promoting processing economy, high value, and remarkable economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] Embodiment 1: ZnAl catalyst

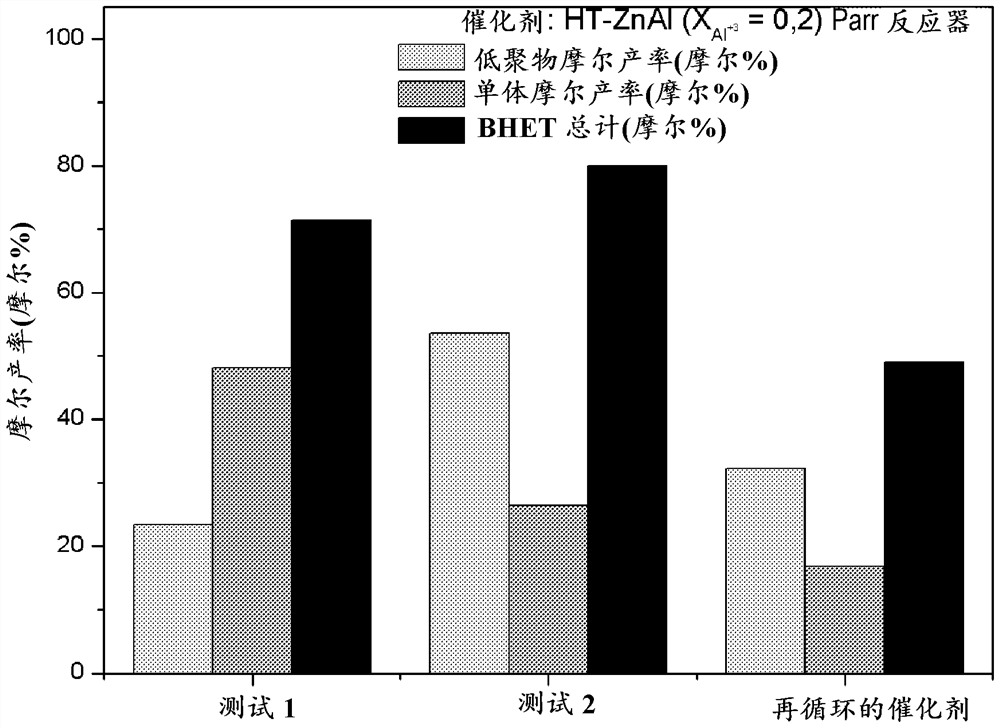

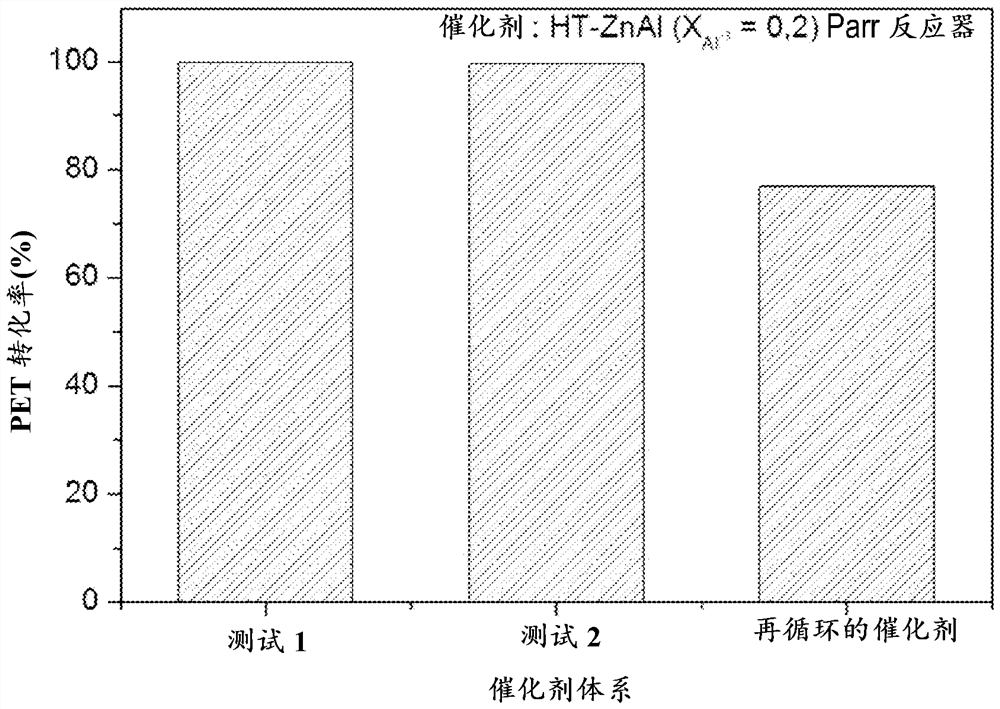

[0098] exist figure 1 The results of PET depolymerization for subsequent repolymerization performed on a large scale in a Parr reactor are shown in . In the batch tests (Tests 1 and 2) with mixed oxide catalysts derived from the hydrotalcite precursor phase HT-ZnAl, good reproducibility was noted. For pristine mixed oxides (tests 1 and 2), after 1 h of reaction, starting from 40 g of PET, the average conversion was 99.7±0.1% (average of tests 1 and 2). For the recycled catalyst system (PET conversion = 76.89%), the same catalyst as used in Test 2 was used, but recovered and utilized in another reaction without any regeneration process. Even though it was not regenerated, the catalyst still proved to be active in the depolymerization reaction, although its catalytic activity showed about 22% drop. exist figure 2 displayed in figure 1 The molar yield results of the tests. The amount of BHET oligomers and monomers obtained differed be...

Embodiment 2

[0099] Example 2: ZnMnAl catalyst for glycolysis of PET and fibers from polyester ropes

[0100] exist image 3 A diagram showing the conversion of PET to BHET by a catalyst of the mixed oxide type obtained from the HT-ZnMnAl precursor phase in which manganese is incorporated in the structure of ZnAl is shown in . The virgin mixed oxide and the reused oxide (recycled catalyst) exhibit practically the same conversion. It is important to emphasize that in this case the catalyst recovered from Test 1 was used for further PET depolymerization, but without the heat treatment of drying and calcination, and complied with the same PET / CAT ratio. It can be observed that when the results of the recycled catalyst are compared with those of the virgin catalyst (Test 1), the results for the conversion of PET to BHET are perfectly reproduced (100% in Test 1, whereas in the recycled catalyst is 99.9%). It is important to emphasize that after conducting Test 1, the catalyst retained on the...

Embodiment 3

[0107] Example 3: NiAl and NiMnAl oxide catalysts for PET glycolysis

[0108] Add 25 ml of ethylene glycol, 5 g of PET and 25 mg of catalyst to a reaction vessel of perfluoroalcoixide wrapped in a metal coating, which is pre-heated at 10 ° C for min -1 Calcined at a rate from ambient temperature to 350 °C and held at this temperature for 3 hours. The system was maintained at ambient temperature for 18 hours for pre- and extended exposure purposes of the reagents. Thereafter, the reaction vessel was heated at 20°C for min -1 Heat at a rate of 200 °C and maintain at final temperature for 1 h under mechanical stirring and autogenous pressure. The listed conditions were achieved using a Mars Synthesis Model 6 microwave reactor from CEM Corporation with temperature control and pressure readout. This phase was divided into two phases: firstly, a Ni catalyst screening test phase, with the aim of optimizing and testing the catalyst exhibiting the maximum conversion. The second sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com