Special machine tool for wire cutting of aviation grille parts

A special machine tool and wire cutting technology, applied in the direction of electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve the difficult breakthrough of molybdenum wire tension and economy, the grid plate is easy to interfere, and the Z-axis CNC drive can not realize the avoidance space and other problems, to achieve the effect of outstanding processing economy, short processing cycle and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

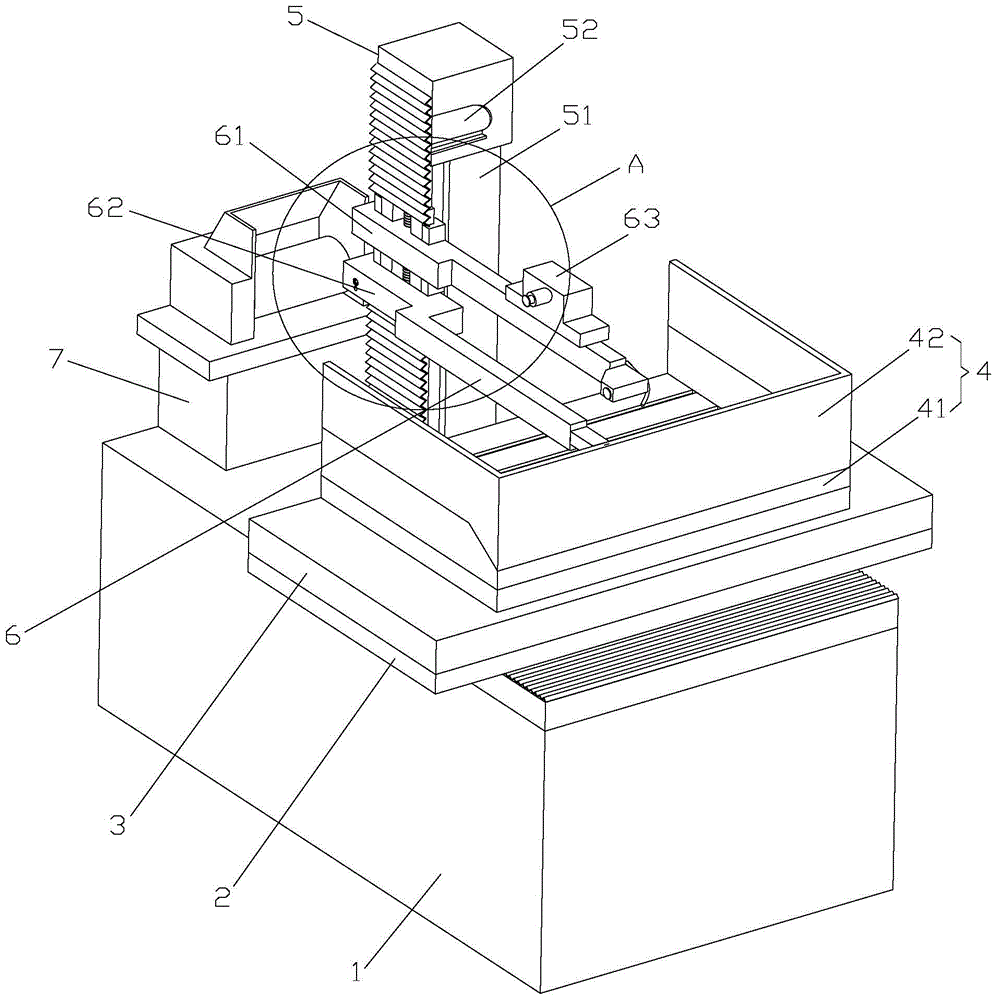

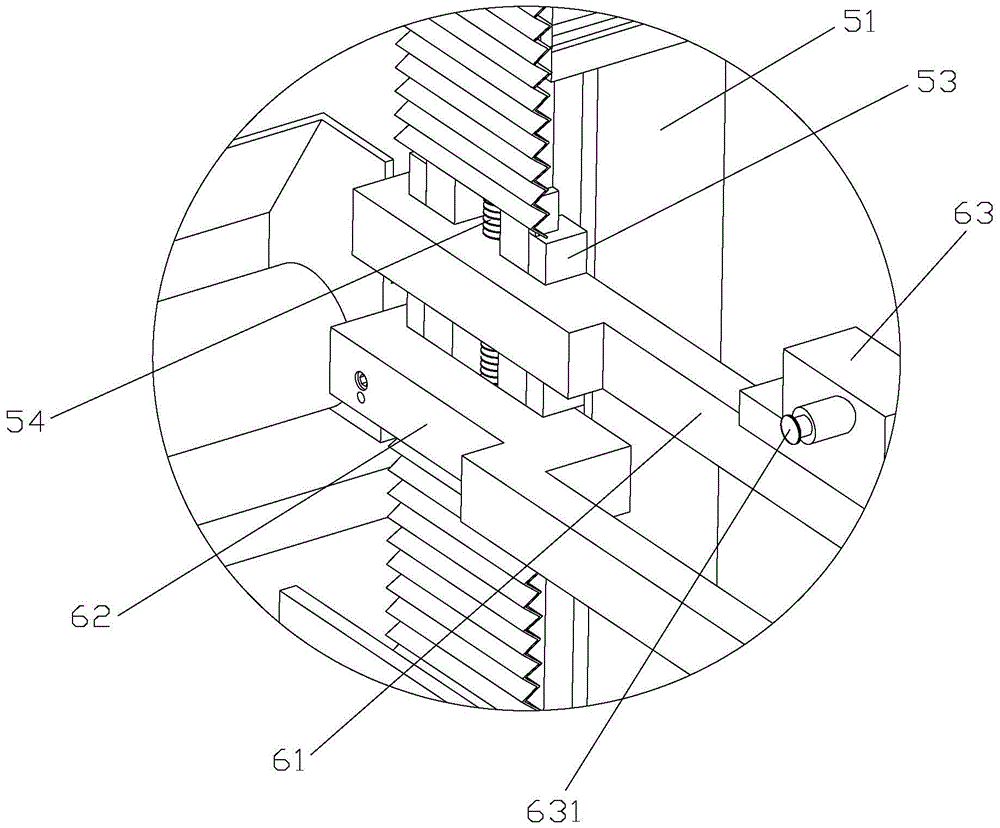

[0030] Such as Figures 1 to 7 As shown, the special machine tool for wire cutting of aerospace grid parts of the present invention includes a bed 1, an X-axis moving mechanism 2, a Y-axis moving mechanism 3, a worktable 4, a Z-axis moving mechanism 5, a wire stand mechanism 6, and a wire transporting part 7. The workpiece clamping tool 8 and the electric control system (not shown in the figure).

[0031] The bed 1 has a rectangular parallelepiped structure as a whole, and there is an accommodating space inside it.

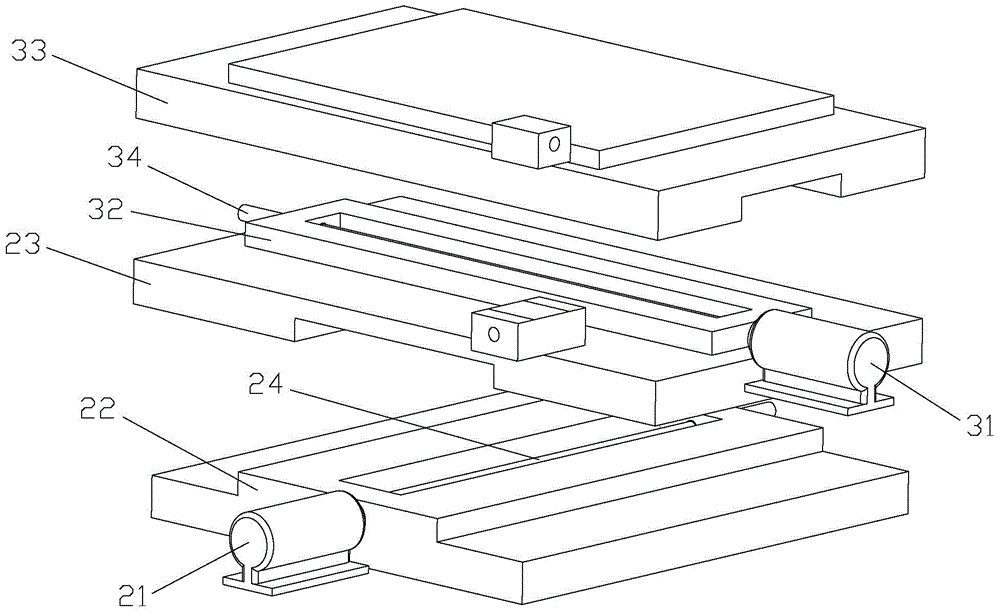

[0032] The X-axis moving mechanism 2 is arranged on the top surface of the bed 1, and includes an X-axis driving motor 21, an X-axis moving guide rail 22, an X-axis moving slide table 23, and an X-axis driving screw 24; wherein, the X-axis driving The motor 21 is mounted on one side of the X-axis moving guide rail 22, and is electrically connected to the electric control system. In this embodiment, the X-axis driving motor 21 adopts a stepper motor; the X-axis mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com