Electric field assisted atomic force microscope nano-etching method

An atomic force microscope and nanotechnology, applied in the field of nanoprocessing, can solve the problems of expensive diamond probes, single diamond scribed shape, and easy torsion of cantilever beams, etc., and achieve flexible processing methods, good isotropic consistency, and low prices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

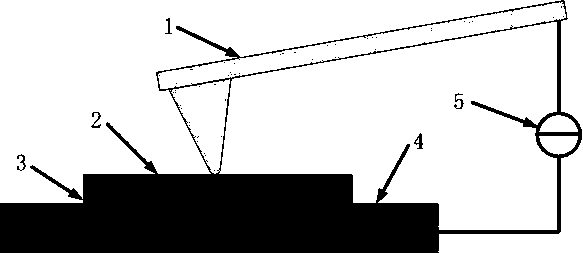

[0018] A programmable current source 5 is applied to the sample 2 and the AFM conductive probe 1 through the power interface provided by the atomic force microscope itself. In principle, the direction of the current does not affect the processing effect. However, considering that the tip is connected to the anode, the discharge voltage is lower. Therefore, the AFM probe is connected to the anode and the sample is connected to the cathode.

[0019] Through the scanning function of the atomic force microscope, the shape of the sample is scanned and the processing position is selected.

[0020] Set the current parameters on the programmable current source 5 . Including current magnitude, duration, current waveform, etc.

[0021] Set the AFM to work in contact mode, so that the AFM probe is in contact with the sample. And the contact force between the probe and the sample is controlled by the Deflection setpoint parameter.

[0022] Plan the trajectory of the probe, and set th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com