Roller bit

A technology of roller cone bit and geological drilling, which is applied in the direction of drill bit, drilling equipment, earth-moving drilling and mining, etc., can solve the problems affecting the processing quality, the service life of the roller cone bit, and the difficulty of machining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

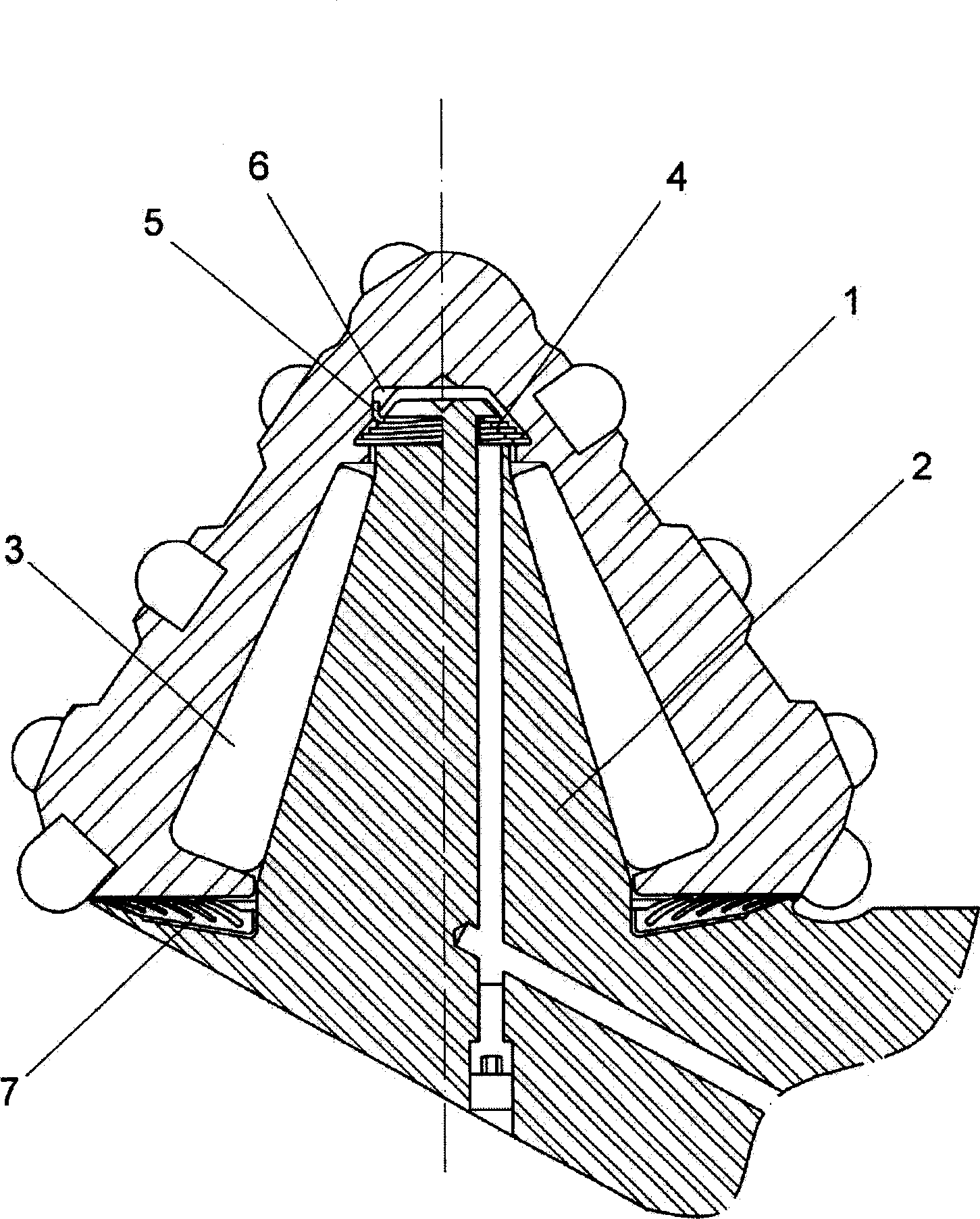

[0019] Such as figure 1 Shown is a schematic cross-sectional view of the cone of the present invention, in which 1 is the cone, 2 is the cone shaft, 3 is the tapered roller, 4 is the tower-type multi-coil spring, 5 is the anti-rotating pin, 6 is the anti-rotating groove, and 7 is Multi-turn thin lip type end face sealing device, the rest is basically similar to a conventional cone, not shown, and will not be repeated.

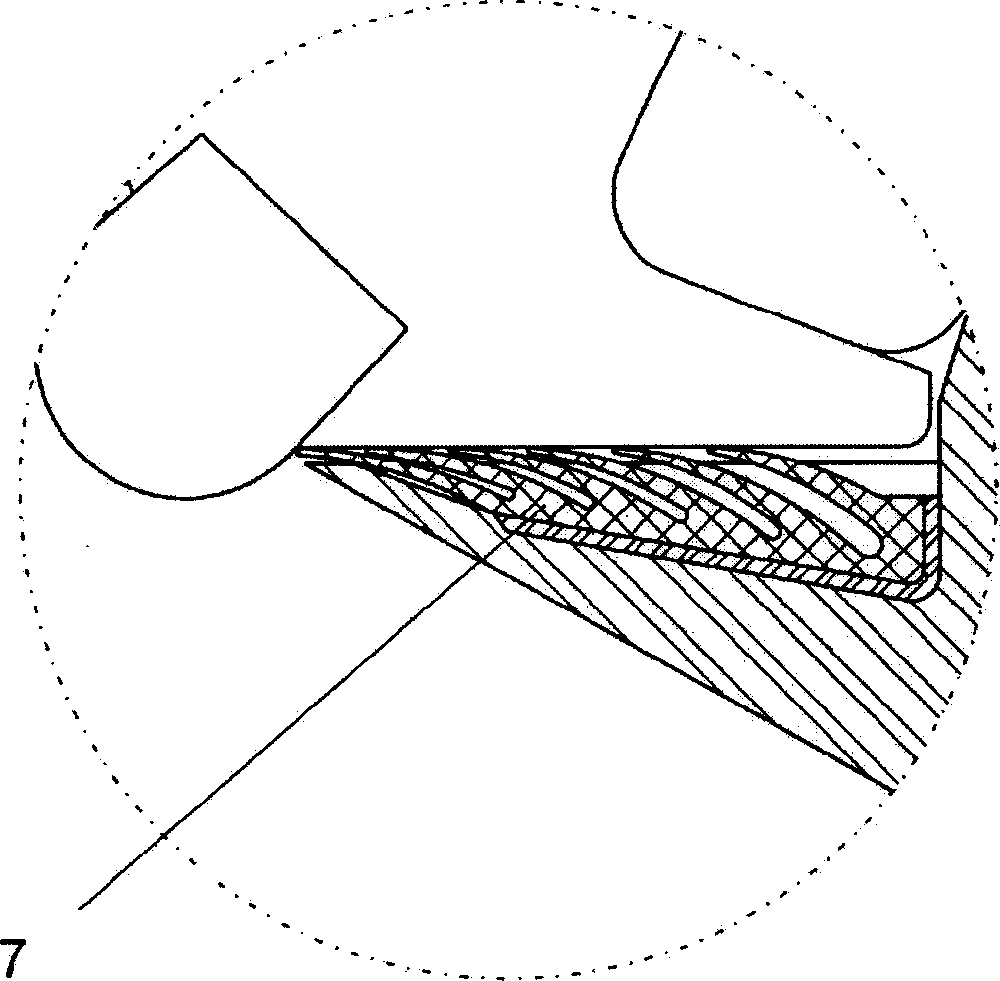

[0020] Such as figure 2 Shown as figure 1 An enlarged schematic diagram of a cross-sectional view of the sealing part.

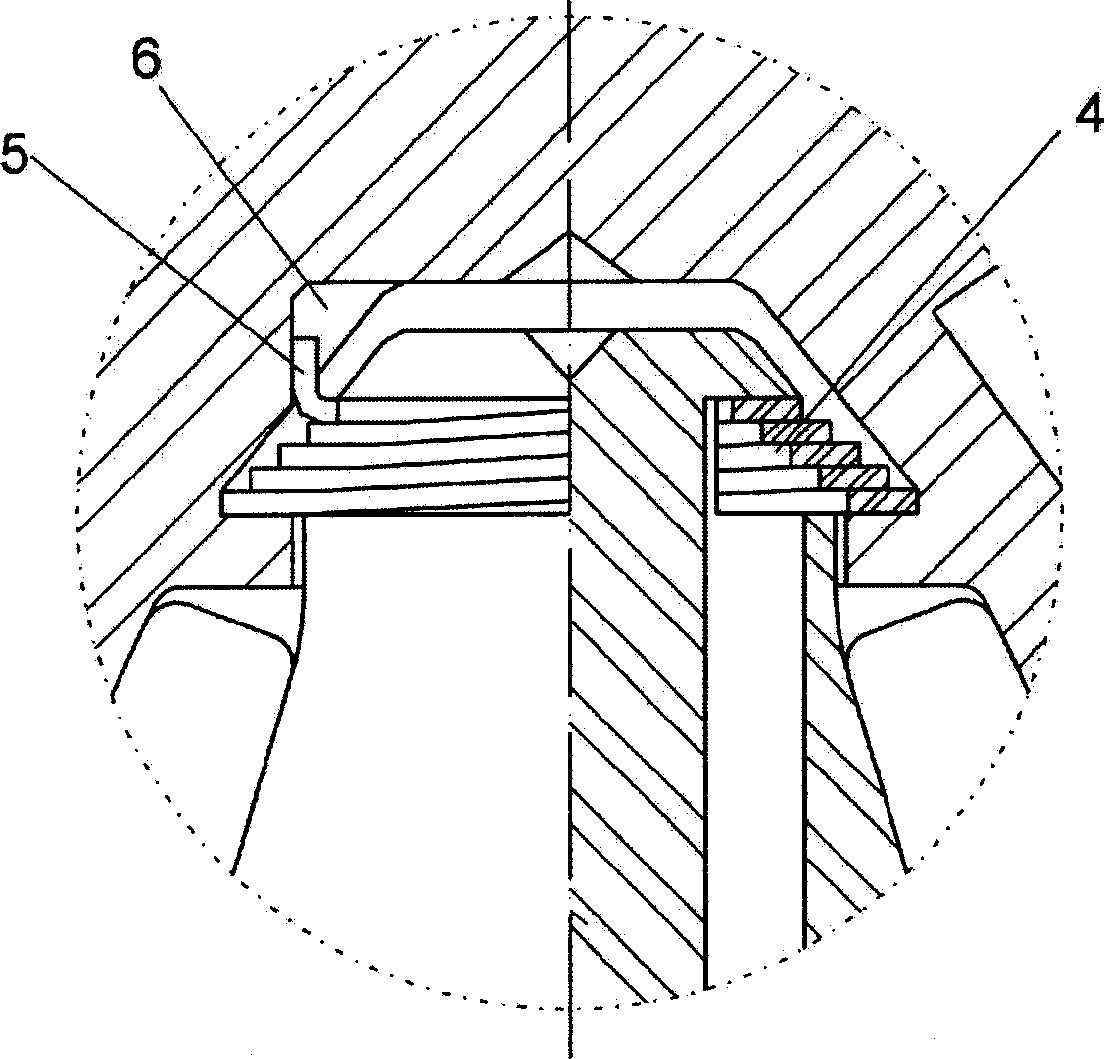

[0021] Such as image 3 Shown as figure 1 An enlarged schematic diagram of the cross-sectional view of the locking part.

[0022] Such as Figure 4 Shown is the front view of the multi-turn thin lip type end face sealing device of the present invention.

[0023] Fig. 5 is a cross-sectional view of the multi-turn thin-lip type end face sealing device of the present invention. It has a metal skeleton 8 for mounting and fixing to the root of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com