Dual-drive reversing valve of heat storage type combustion furnace

A technology for reversing valves and combustion furnaces, applied in the field of reversing valves, can solve problems such as damage, unstable structure of reversing valves, exhaust gas waste heat cannot be fully utilized, etc., to achieve the effect of saving energy and increasing temperature values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

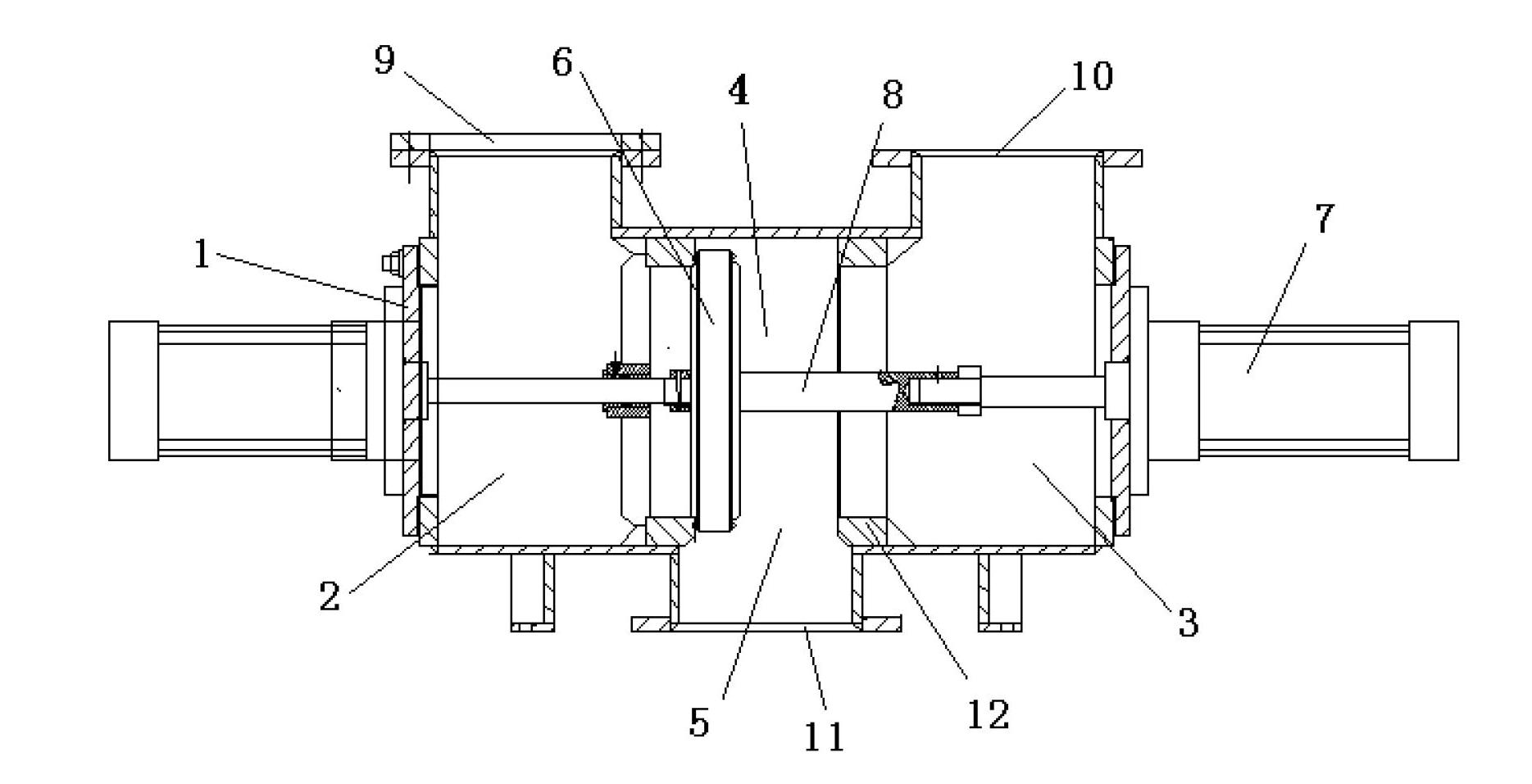

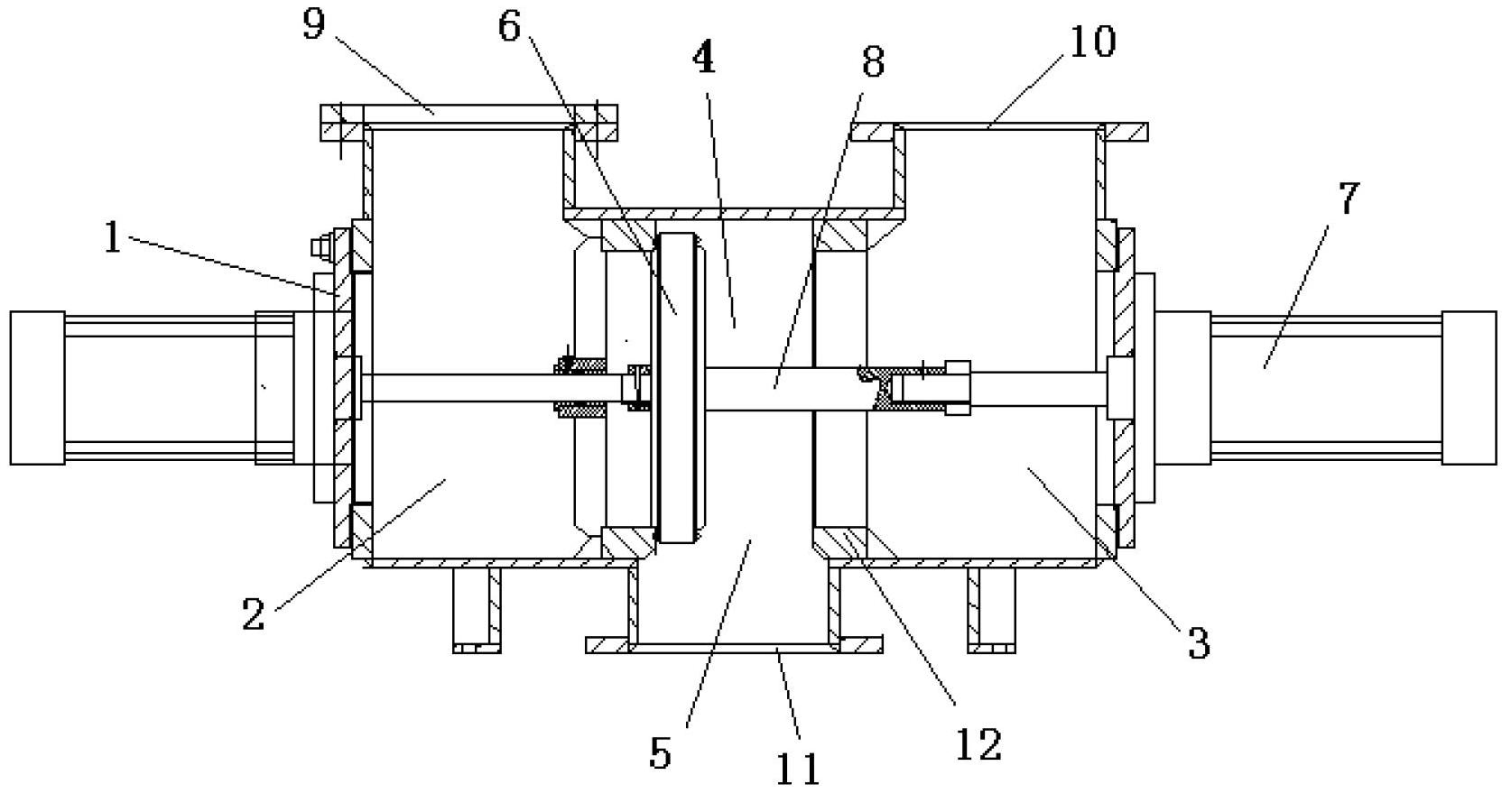

[0010] Referring to the accompanying drawings, a dual-drive reversing valve for a regenerative combustion furnace includes a reversing valve housing 1, and the interior of the reversing valve housing 1 is divided into two left flue gas chambers 2 and right air chambers 3 chamber, a communication passage 4 is provided between the air chamber 3 and the gas chamber 2, a utility chamber 5 is provided below the communication passage 4, and valve plate sealing discs 12 are provided on the side walls at both ends of the communication passage 4 A valve plate 6 is blocked in the communication channel 4 between the smoke chamber 2 and the air chamber 3, and two hydraulic cylinders 7 are fixedly installed on the left and right outer walls of the smoke chamber 2 and the air chamber 3 respectively, The piston rods of the left and right hydraulic cylinders 7 extend into the smoke chamber 2 and the air chamber 3 respectively, and a rod crossing the smoke chamber 2 and the air chamber 3 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com