Adjustable pulsating flow enhanced heat transfer heat exchanger

A technology for enhancing heat transfer and pulsating flow, applied in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as no proposed structural form, and achieve simple structure, enhanced heat transfer, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings, but this description will not constitute a limitation to the present invention.

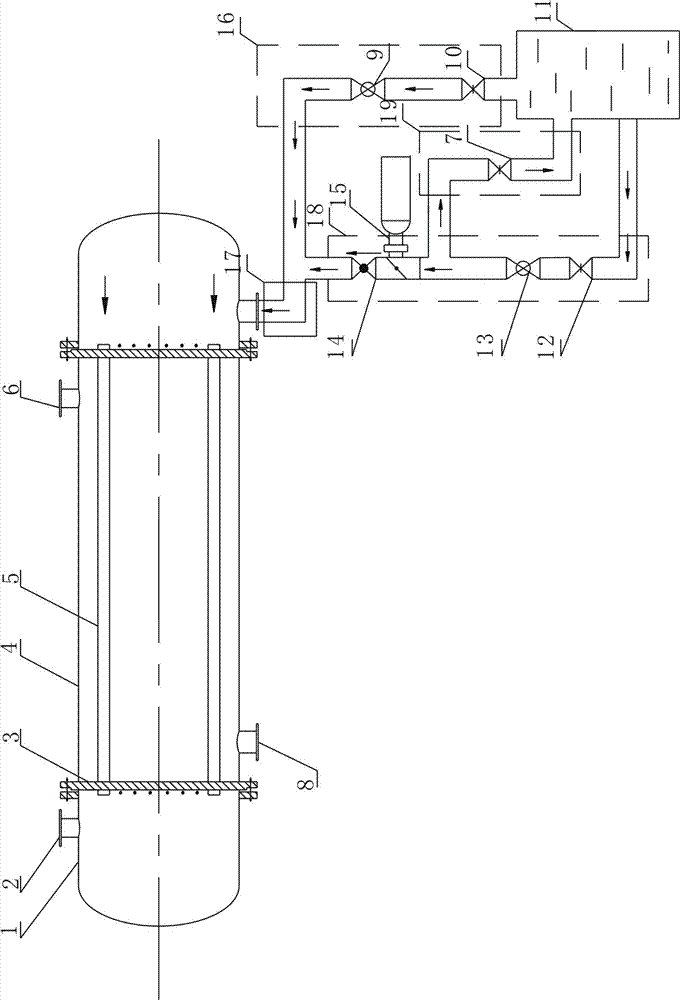

[0018] like figure 1 As shown in the figure, the adjustable pulsating flow enhanced heat transfer heat exchanger includes a shell 4, a head 1, a tube sheet 3 and a heat exchange tube 5. The inlet end of the heat pipe is fixed on the tube sheet, and the shell is also provided with a shell side inlet 8 and a shell side outlet 6, of which the tube side inlet on one side of the head (the other side of the head is provided with a tube side outlet 2 ). ) is connected to a multi-channel adjustable pulsating flow generating device, and its amplitude and frequency are adjusted by adjusting the rotational speed of the multi-channel adjustable pulsating flow generating device and the flow rate of the branch where it is located, and the multi-channel adjustable pulsating flow generating device includes: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com