Lever-type drawing device for testing anchoring performance of planting bar and implementation method thereof

A technology of anchoring performance and pulling device, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of personnel injury, poor load stability, and damage to test devices, etc., to solve the problem of unstable load and reduce The load value at the loading end, the effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

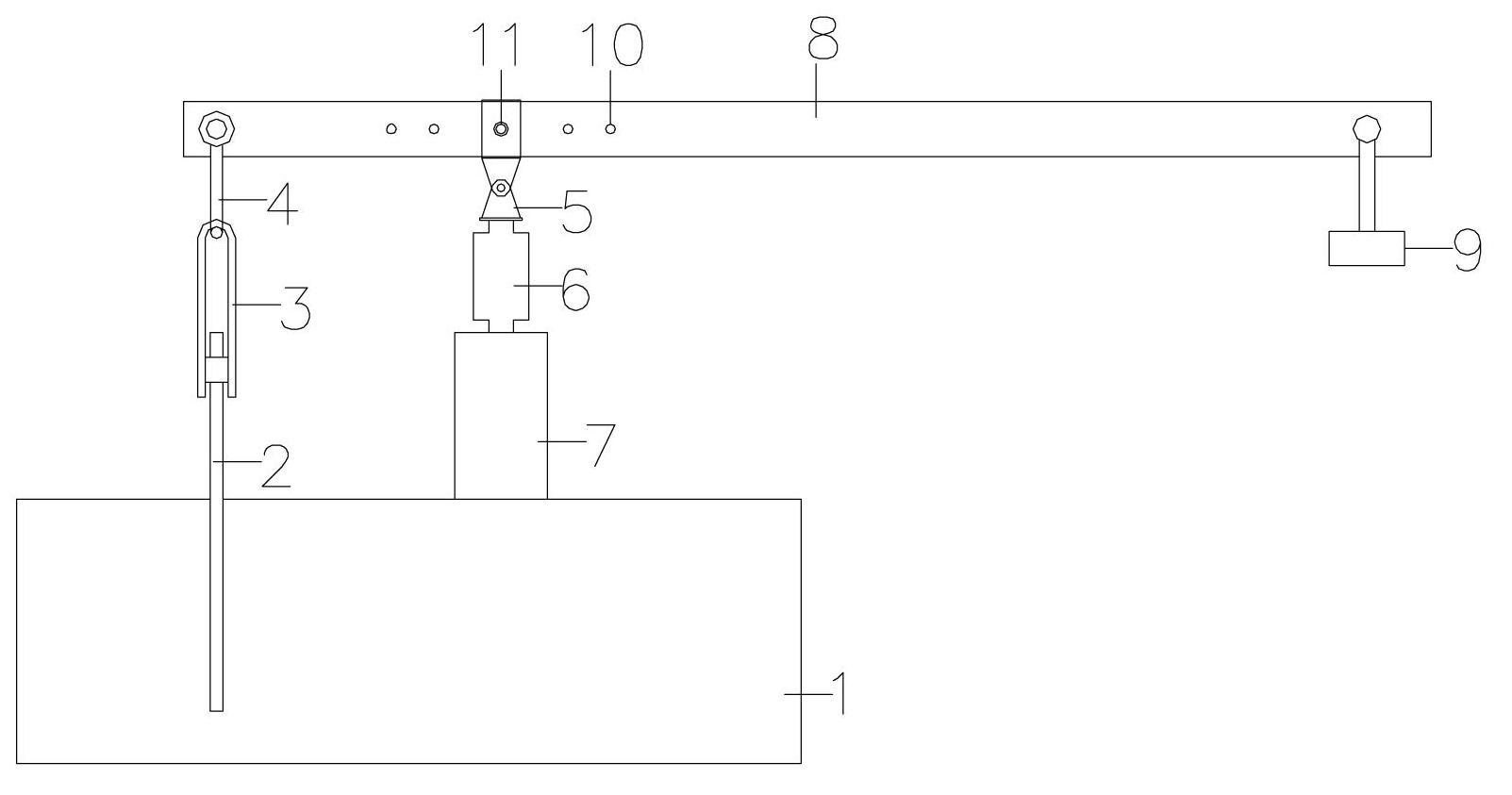

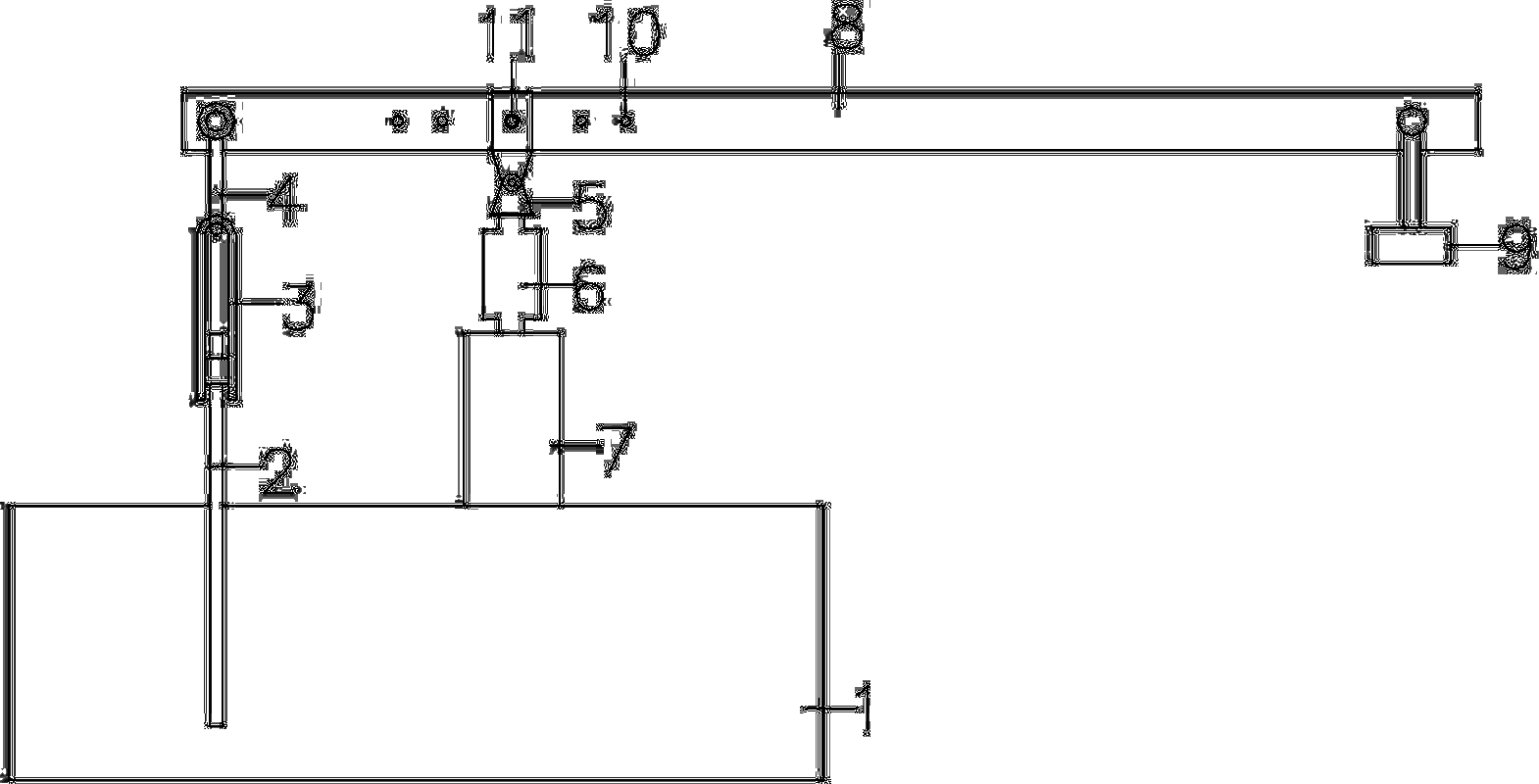

[0035] An implementation method of a lever-type pulling device for anchorage performance testing of planted bars, comprising the following steps,

[0036] The first step is to install rigid pads, tension and pressure sensors and supports in sequence on the concrete substrate;

[0037] The second step is to connect the support to the limit pin hole on the rigid beam, and limit the position through the limit pin;

[0038] The third step is to install a U-shaped shackle at one end of the rigid beam, and connect it to the planting bar through a U-shaped connector;

[0039] The fourth step is to connect the loading device at the other end of the rigid beam;

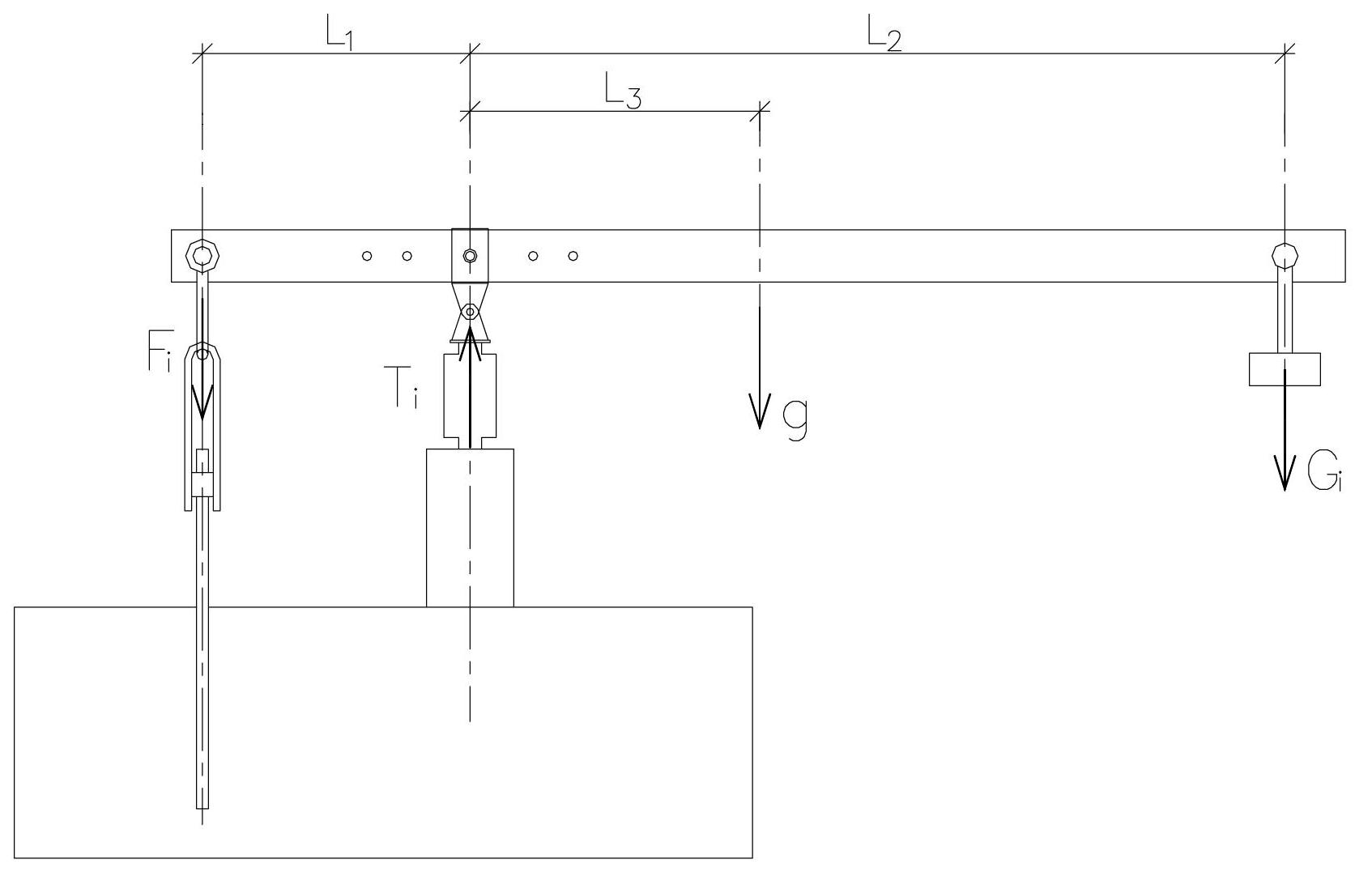

[0040] The fifth step is to measure the distance L between the center of the support and the center of the U-shaped shackle 1 , the distance L between the center of the support and the center of the loading device 2 , the distance L from the center of gravity of the rigid beam to the center of the support 3 and the self-we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com