Method and system for identifying salient-point mould number of revolution-solid glass bottle based on images

A recognition method and glass bottle technology, applied in the directions of character and pattern recognition, image analysis, image data processing, etc., can solve the problems of equipment layout space limitation, high-precision mold number real-time recognition, etc., and achieve easy promotion and use, simple structure and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

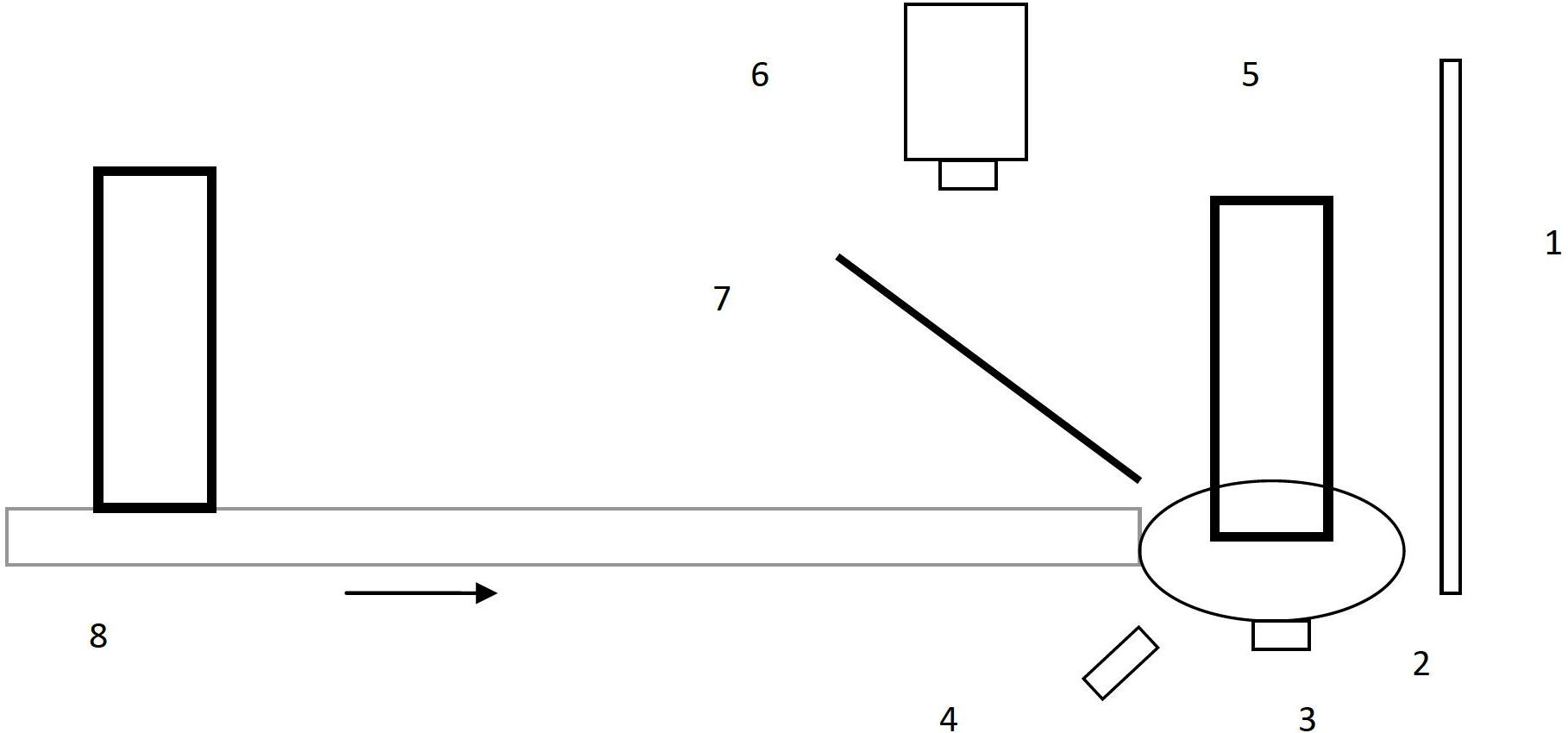

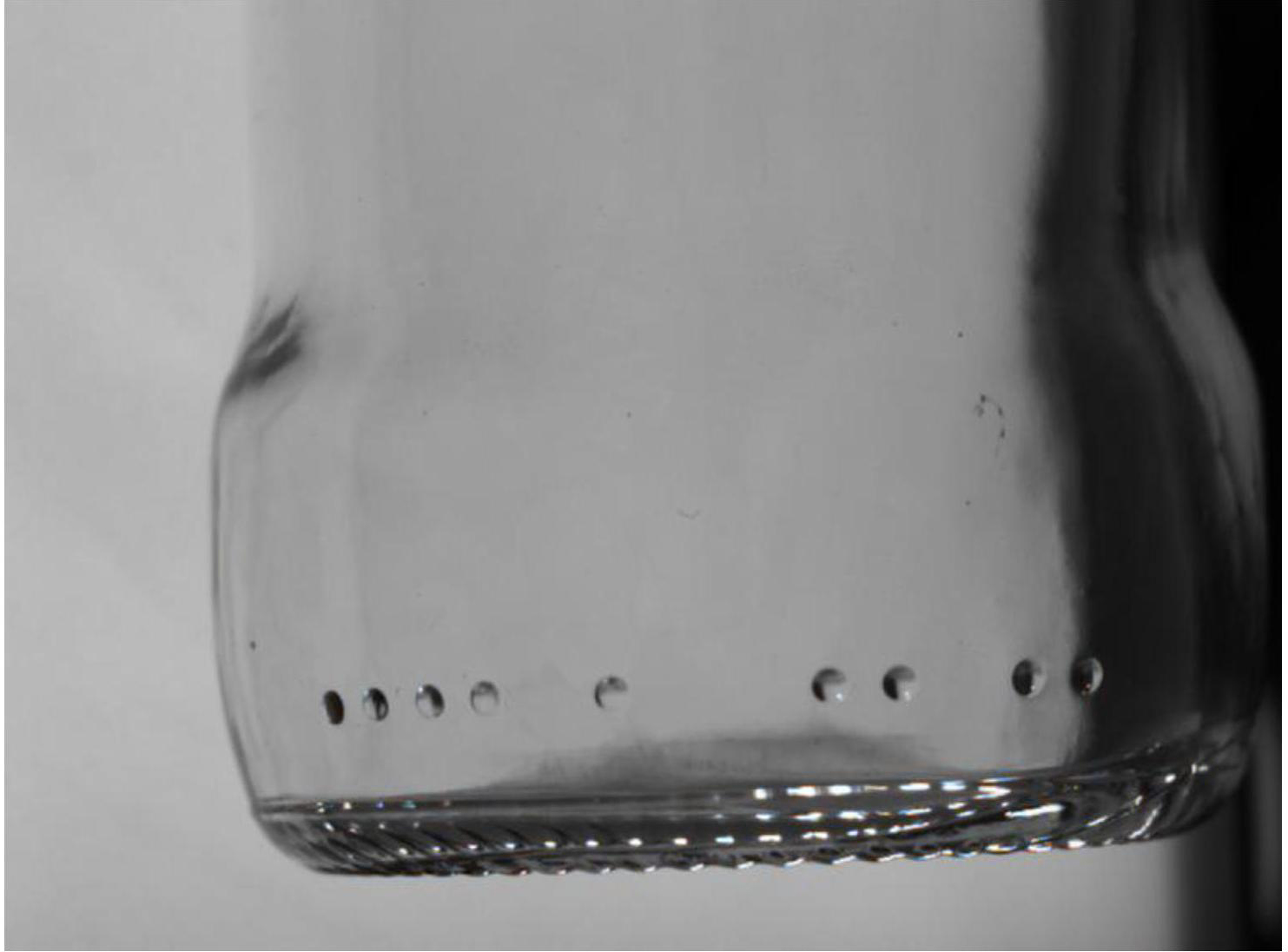

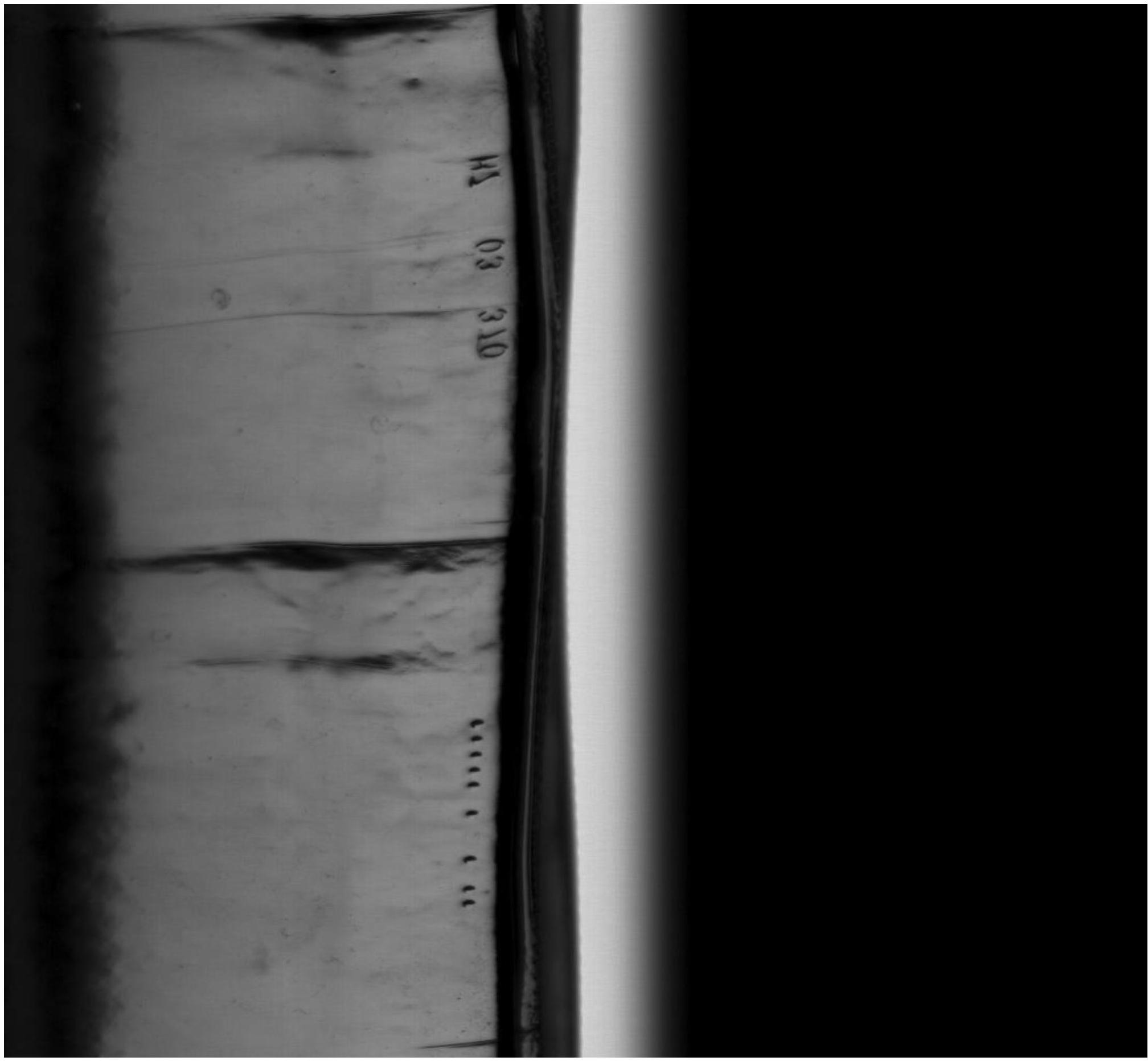

[0032] Such as figure 1 As shown, an image-based recognition system for glass bottle bump mold number of gyrotron, which includes LED surface light source 1, rotary platform 2, rotary encoder 3, photoelectric sensor 4, CCD camera 5, plane mirror 7, product conveyor belt 8, Among them, the rotary platform 2 is connected with the rotary encoder 3, the LED surface light source 1 is arranged behind the rotary platform 2, the product conveyor belt 8 is connected with the rotary platform 2, and the CCD camera 6 is arranged obliquely in front of the rotary platform 2, and the CCD camera 6 and the product conveyor belt A plane mirror 7 is arranged between 8, and a photoelectric sensor 4 is arranged on the other side of the product conveyor belt 8, obliquely in front of the rotating platform 1.

[0033] The LED surface light source 1 illuminates the glass bottl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com