Lid opening and closing device

A technology of opening and closing device and cover body, which is used in transportation and packaging, semiconductor/solid-state device manufacturing, conveyor objects, etc., and can solve problems such as insufficient removal and inability to process wafers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

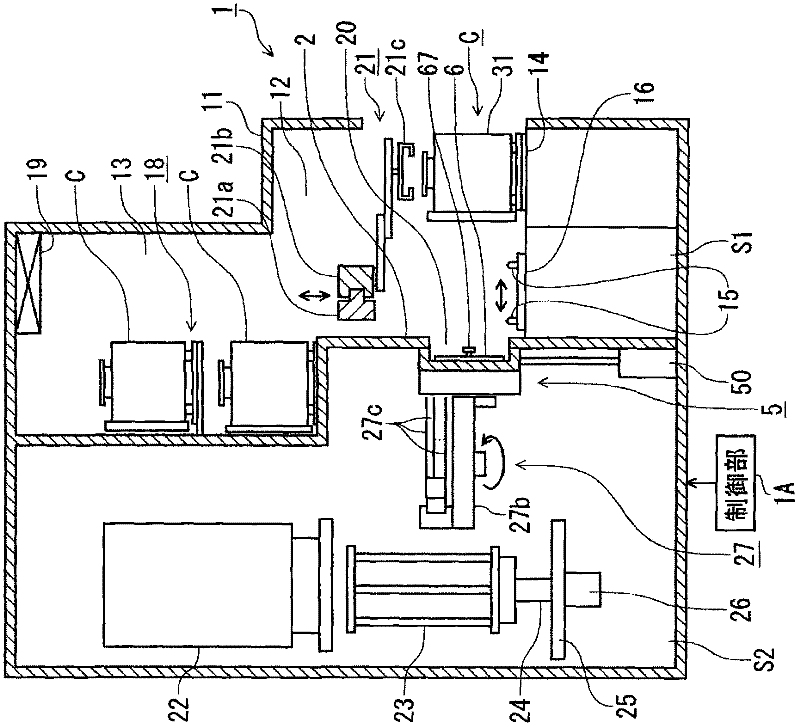

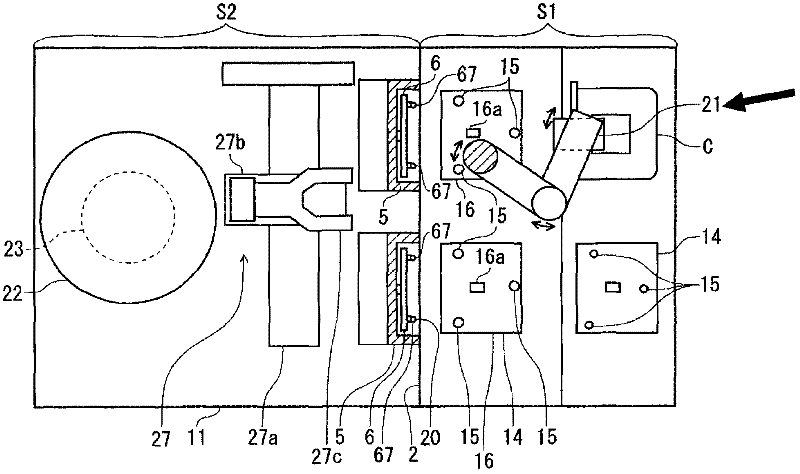

[0042] A vertical heat treatment apparatus incorporating the lid opening and closing device of the present invention will be described. figure 1 It is a longitudinal sectional view of the vertical heat treatment apparatus 1, figure 2 It is a plan view of the vertical heat treatment apparatus 1 . Reference numeral 11 in the figure is a frame body constituting the outer casing of the vertical heat treatment apparatus 1. In the frame body 11, a carrier transport area S1 is formed, which is used for carrying in and out of the apparatus as a storage object to be processed. That is, the carrier C of the container of the wafer W; the wafer transport area S2, which is used as a transfer area, is used to transport the wafer W in the carrier C and carry the wafer W into a heat treatment furnace described later. Carrier C is a FOUP as described above.

[0043]The carrier transfer area S1 and the wafer transfer area S2 are separated by a partition wall 2 . The carrier transport area ...

no. 2 Embodiment approach

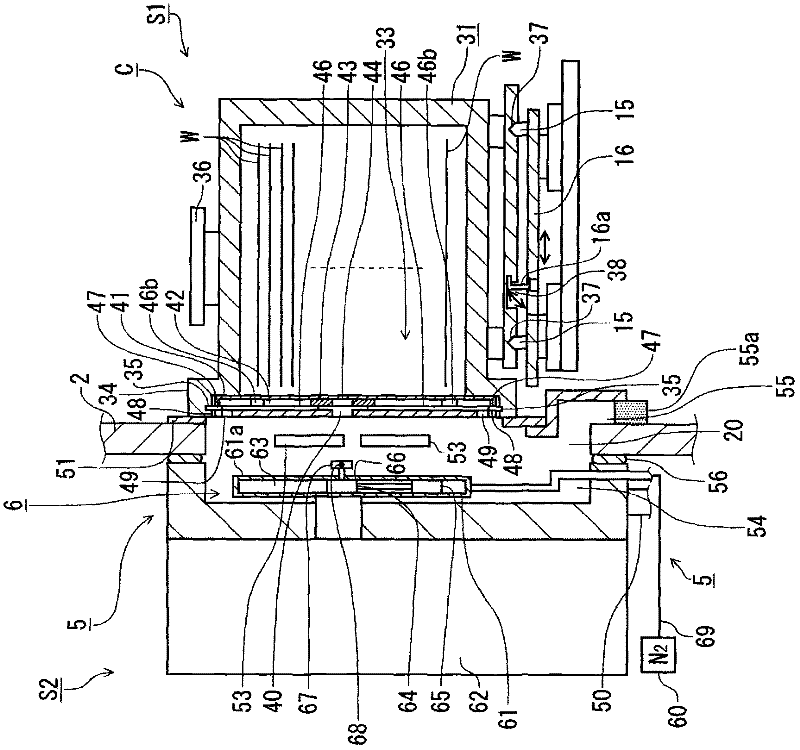

[0072] Next, the second embodiment will be described focusing on the points of difference from the first embodiment. Figure 17 The perspective view which shows the removal mechanism 6 of the cover body 41 of this 2nd Embodiment. In this detachment mechanism 6 , instead of the gas discharge port 68 formed in the key 67 , a plurality of gas discharge ports 73 are opened in the plane direction of the facing surface 61 a of the facing plate 61 of the detachment mechanism 6 . The gas ejection port 73 is connected to the internal space 63 of the counter plate 61 . And, the downstream end of the gas supply pipe 69 is opened to the internal space 63 , and the gas injected into the internal space 63 is N 2 Gas is ejected from the gas ejection port 73 in the thickness direction of the opposing plate 61 . That is, in this example, the opposing plate 61 is formed as a shower head-shaped purge gas ejection portion.

[0073] For example, in the state where the key 67 is engaged with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com