Liquid crystal display device and manufacturing method therefor

A technology of a liquid crystal display device and a manufacturing method, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as hindering the conduction of terminal circuit chips, and achieve the effect of suppressing expansion and reducing non-display areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0047] Figure 1 to Figure 6 Embodiment 1 of this invention is shown.

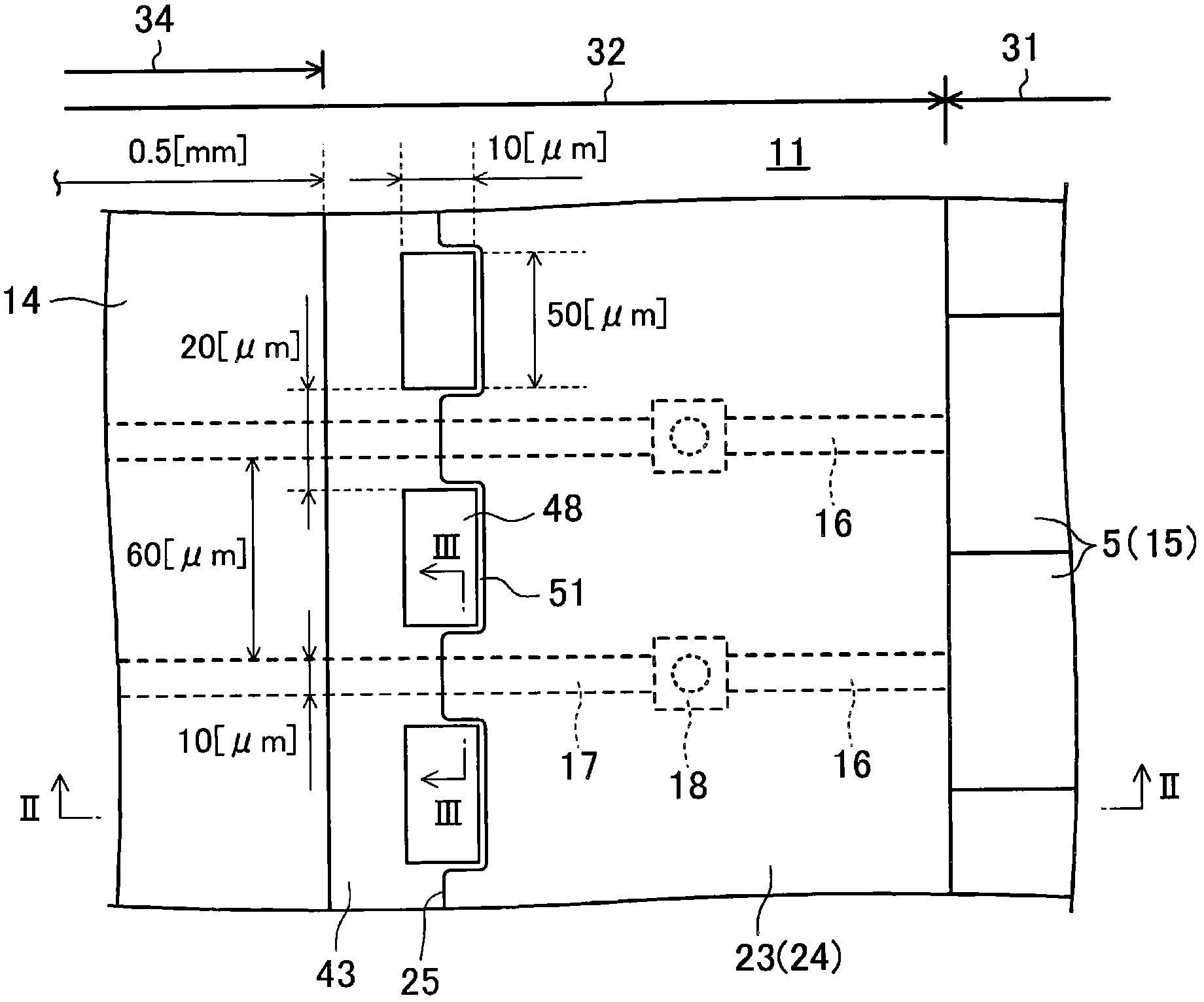

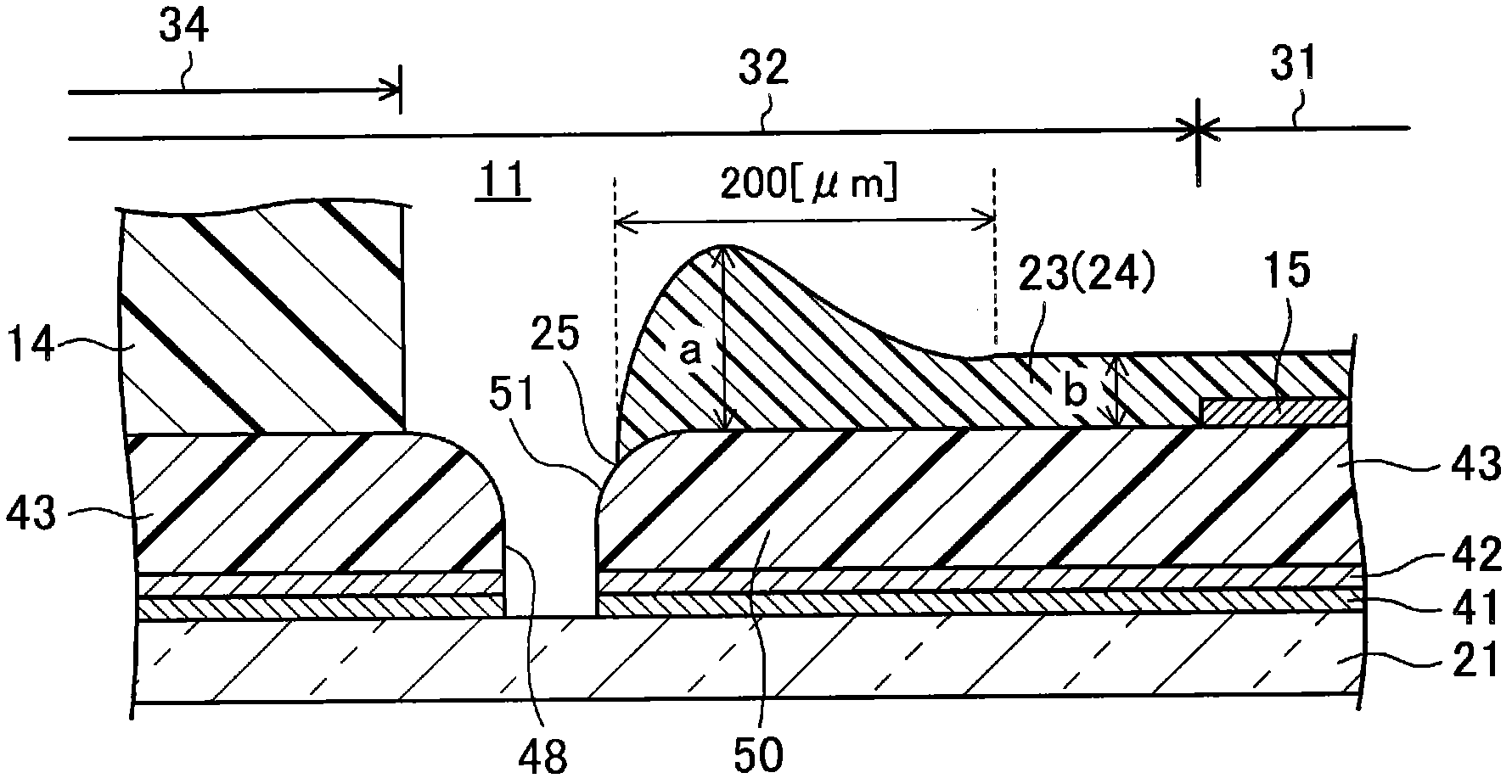

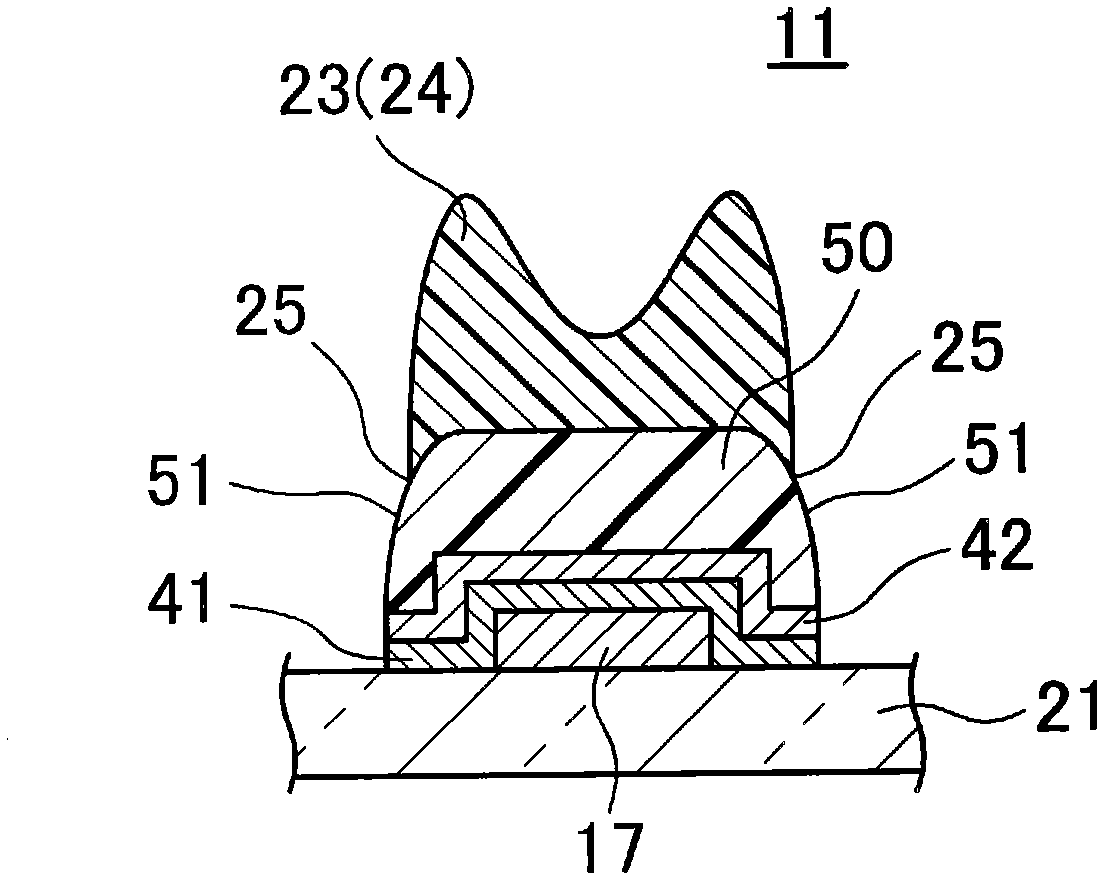

[0048] figure 1 It is a plan view showing an enlarged part of the TFT substrate 11 of the first embodiment. figure 2 yes figure 1 The II-II line sectional view. image 3 yes figure 1 Sectional view of line III-III. Figure 4 It is a plan view showing a schematic configuration of the liquid crystal display device 1 of the first embodiment.

[0049] in addition, Figure 5It is an enlarged plan view showing a part of the counter substrate 12 of the first embodiment. Figure 6 yes Figure 5 The VI-VI line sectional view. Figure 7 With Figure 4 Comparable diagram of line section VII-VII. Figure 8 It is an enlarged cross-sectional view showing the supporting structure portion 50 of the TFT substrate 11 .

[0050] Figure 9 It is an enlarged plan view showing a part of the TFT substrate 11 . In addition, in Figure 9 In , the illustration of the alignment film 23 and the concave portion 48 w...

Embodiment approach 2

[0106] Figure 10 Embodiment 2 of this invention is shown.

[0107] Figure 10 It is an enlarged cross-sectional view illustrating the structure of the TFT substrate 11 according to the second embodiment. In addition, in each of the following embodiments, for the Figure 1 to Figure 8 The same reference numerals are attached to the same parts, and detailed description thereof will be omitted.

[0108] In Embodiment 1 above, the planarizing film 43 is formed on the sealing member forming region 34 , but in Embodiment 2, the sealing member 14 is formed on the glass substrate 21 , and there is no intervening support between the sealing member 14 and the glass substrate 21 . The planarizing film 43 is a constituent material of the structural portion 50 .

[0109] That is, in the sealing member forming region 34 of the TFT substrate 11 , the gate insulating film 41 , the passivation film 42 , and the planarizing film 43 are removed from the glass substrate 21 by etching or the ...

Embodiment approach 3

[0112] Figure 11 Embodiment 3 of this invention is shown.

[0113] Figure 11 It is an enlarged cross-sectional view showing the structure of the TFT substrate of Embodiment 3. FIG.

[0114] In the first embodiment described above, the plurality of recesses 48 are formed at predetermined intervals from the sealing member 14 , but in the third embodiment, the sealing member 14 is also formed inside each recess 48 . That is, the sealing member 14 is arranged in contact with the side end of the support structure portion 50 in a state of being separated from the edge portion 25 of the alignment film 23 (orientation film material 24 ).

[0115]Therefore, according to this third embodiment as well, by providing the above-mentioned support structure portion 50 , the same effect as that of the above-mentioned first embodiment can be obtained. In addition, since the sealing member 14 is in contact with the side end of the support structure portion 50 while being separated from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com