Display panel and inspection method thereof

A technology for a display panel and an inspection method, which is applied to static indicators, instruments, electroluminescent light sources, etc., can solve the problem that the source driver 94 has not been installed yet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0101] (1.1 overall structure)

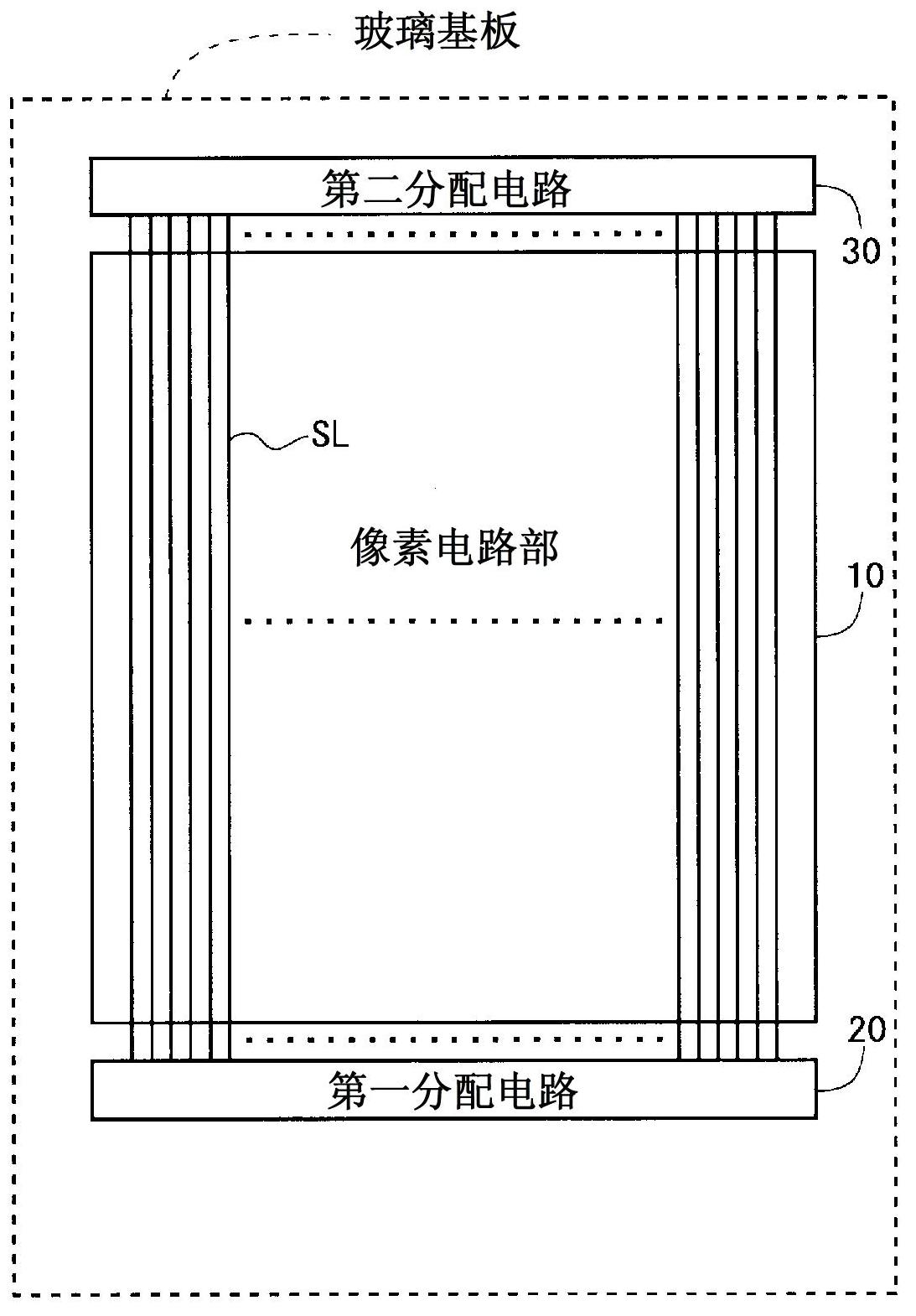

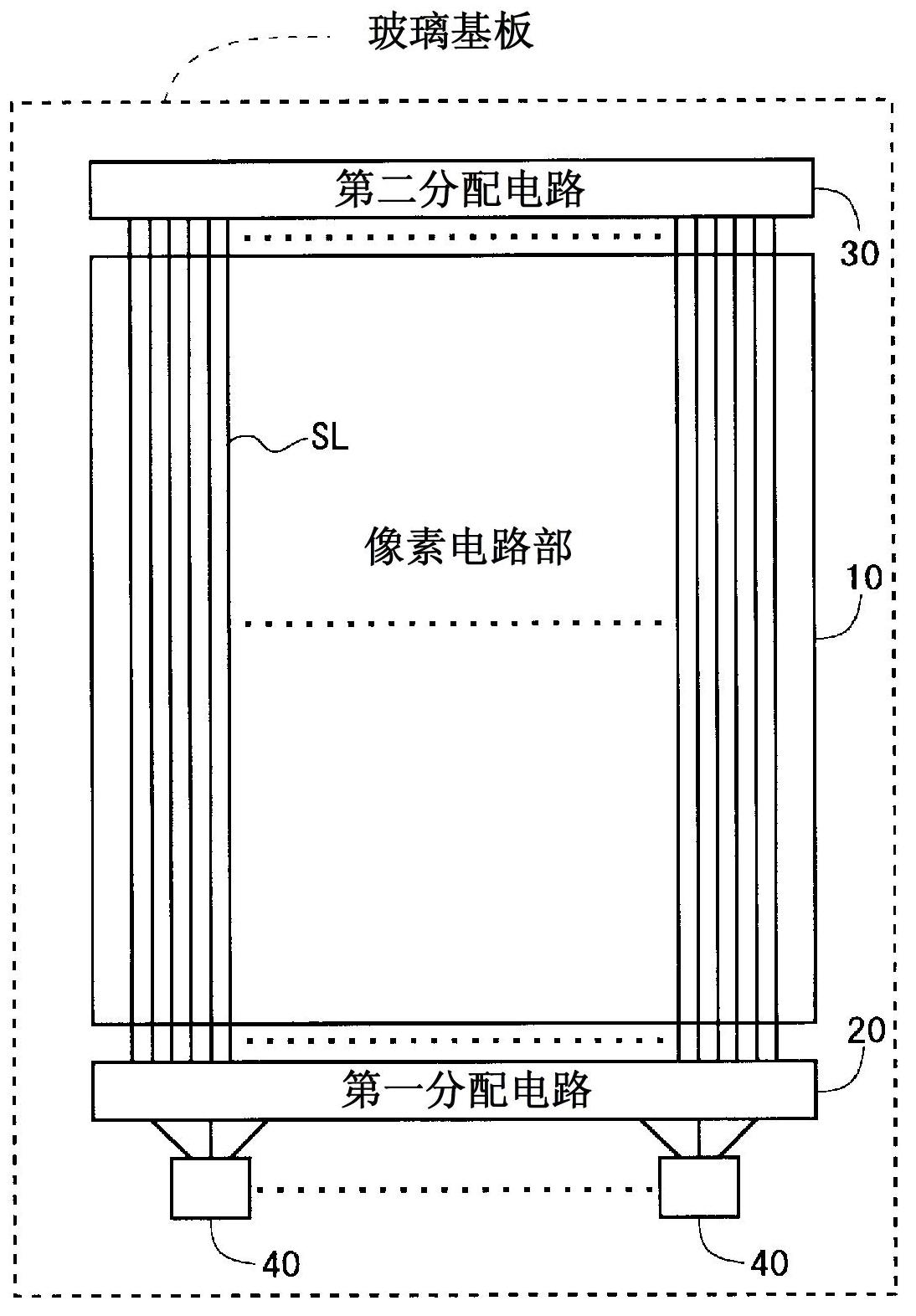

[0102] figure 2 It is a block diagram showing the configuration of main parts of the liquid crystal panel according to the first embodiment of the present invention. Such as figure 2 As shown, this liquid crystal panel includes: a pixel circuit unit 10 serving as an area for displaying an image; and a first distribution circuit 20 and a second distribution circuit 30 having a function of switching and outputting a signal supplied from the outside to a plurality of signal lines. The pixel circuit unit 10, the first distribution circuit 20, and the second distribution circuit 30 are formed on one of the two glass substrates constituting the liquid crystal panel (generally referred to as an "array substrate").

[0103] The pixel circuit section 10 includes a plurality of source bus lines (video signal lines) SL, a plurality of gate bus lines (scanning signal lines), and a plurality of pixels respectively provided corresponding to the intersect...

no. 2 approach

[0159] (2.1 Structure and operation of distribution circuit)

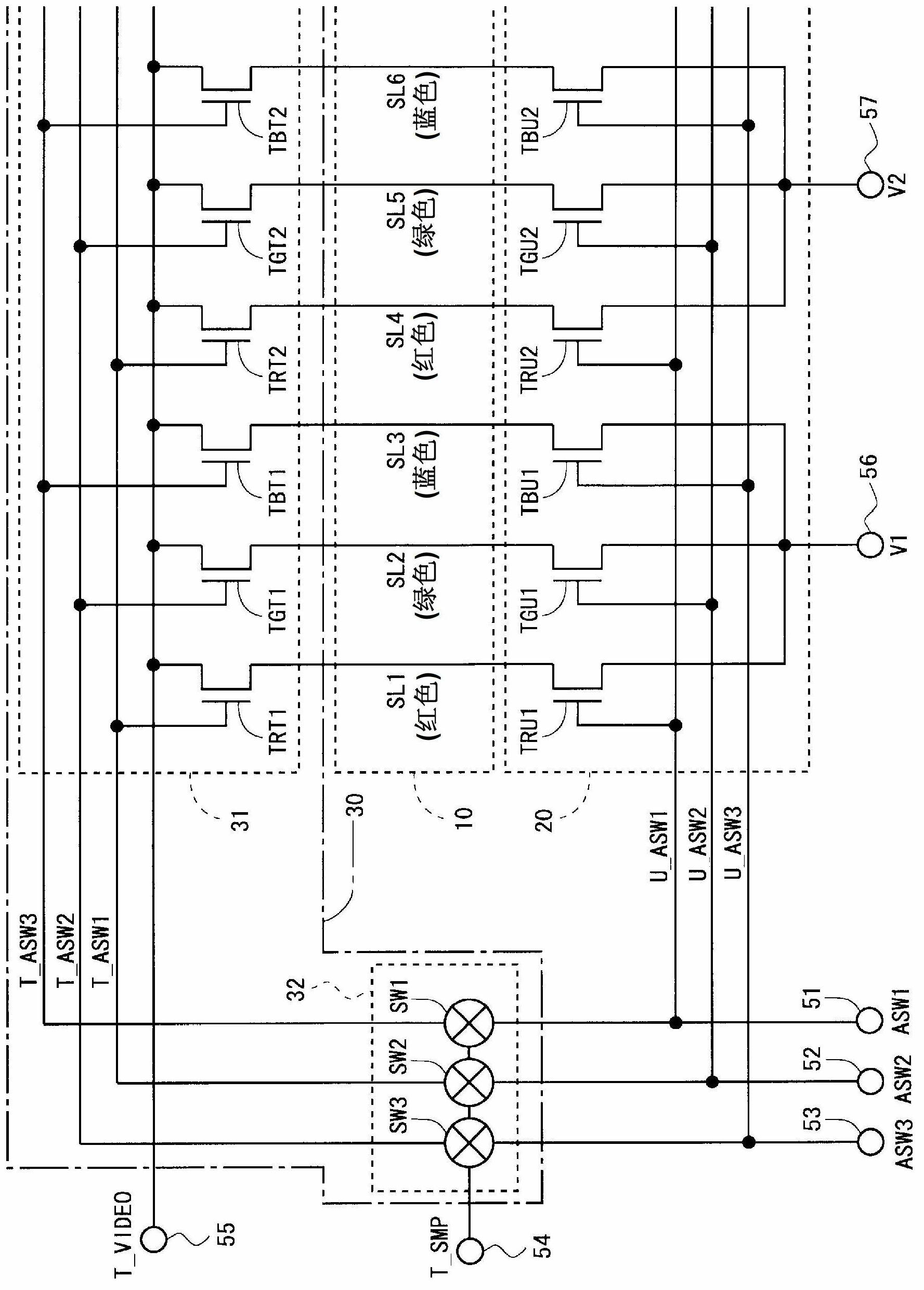

[0160] Figure 19 It is a circuit diagram showing the detailed configuration of the first distribution circuit 20 and the second distribution circuit 30 according to the second embodiment of the present invention. In addition, in figure 1 In , only six source bus lines SL1 to SL6 among the plurality of source bus lines are shown. Regarding the overall structure of the liquid crystal panel, since it is the same as that of the above-mentioned first embodiment, description thereof will be omitted (see figure 2 , image 3 ). In this embodiment, unlike the above-mentioned first embodiment, a demultiplexer having one input and six outputs is provided in the first distribution circuit 20 for every six source bus lines. Similarly, the distribution unit 35 in the second distribution circuit 30 is also provided with a demultiplexer with 1 input and 6 outputs for every six source bus lines. when looking at the Figur...

no. 3 approach

[0190] (3.1 Structure)

[0191] The structure of the liquid crystal panel of the third embodiment of the present invention is the same as that of the first embodiment (refer to Figure 1 to Figure 5 ). In the first embodiment, the second distribution circuit 30 is used as a circuit for panel inspection (typically before mounting the driver IC), but in this embodiment, it is used as a circuit for precharging (pre-charging) the source bus line. circuit use. Therefore, this second distribution circuit 30 can be used not only as a circuit for panel inspection, but also as a circuit for precharging. In addition, for convenience of description, the "video signal for testing" in the first embodiment is called "video signal for precharging", and the "switch for inspection" in the first embodiment is called "switch for precharging".

[0192] (3.2 Driving method)

[0193] Below, refer to Figure 29 , the driving method of the source bus line when the second distribution circuit 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com