Tensioning disassembly-free head board on square pile die

A technology for square pile moulds, assembly and disassembly heads, which is applied to moulds, manufacturing tools, ceramic molding machines, etc., can solve the problems of high labor intensity, high wage expenses, and low work efficiency, and achieve labor intensity reduction, reasonable structure, The effect of reducing the assembly and disassembly process and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

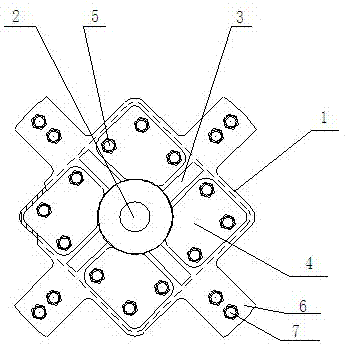

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0010] Such as figure 1 As shown, a square pile mold tensioning free head plate includes a frame-shaped head plate body 1, and a connecting plate 6 is arranged on the outside of each side of the frame-shaped head plate body 1, and a connecting plate 6 is opened on the connecting plate 6. There is a threaded hole 7 matching the threaded hole on the mold, and a tension screw hole 2 is provided at the center of the head plate body 1, and a tension screw hole 2 is fixedly connected to the inner side of each side of the head plate body 1. Reinforcing ribs 3 , two adjacent reinforcing ribs 3 and the edges on the head plate body 1 connected to them form a void area 4 , and each void area 4 accommodates at least one connecting bolt between the end plate and the tension plate. After calculating the supporting force of the head plate and correspondingly increasing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com