Vehicle-mounted adhesive tape conveyor

A belt conveyor and vehicle-mounted technology, which is applied in the field of mobile conveying equipment, can solve problems such as high labor intensity, low operating efficiency, heavy and inconvenient movement, etc., and achieve the effects of improving work efficiency, reducing power consumption, and improving conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

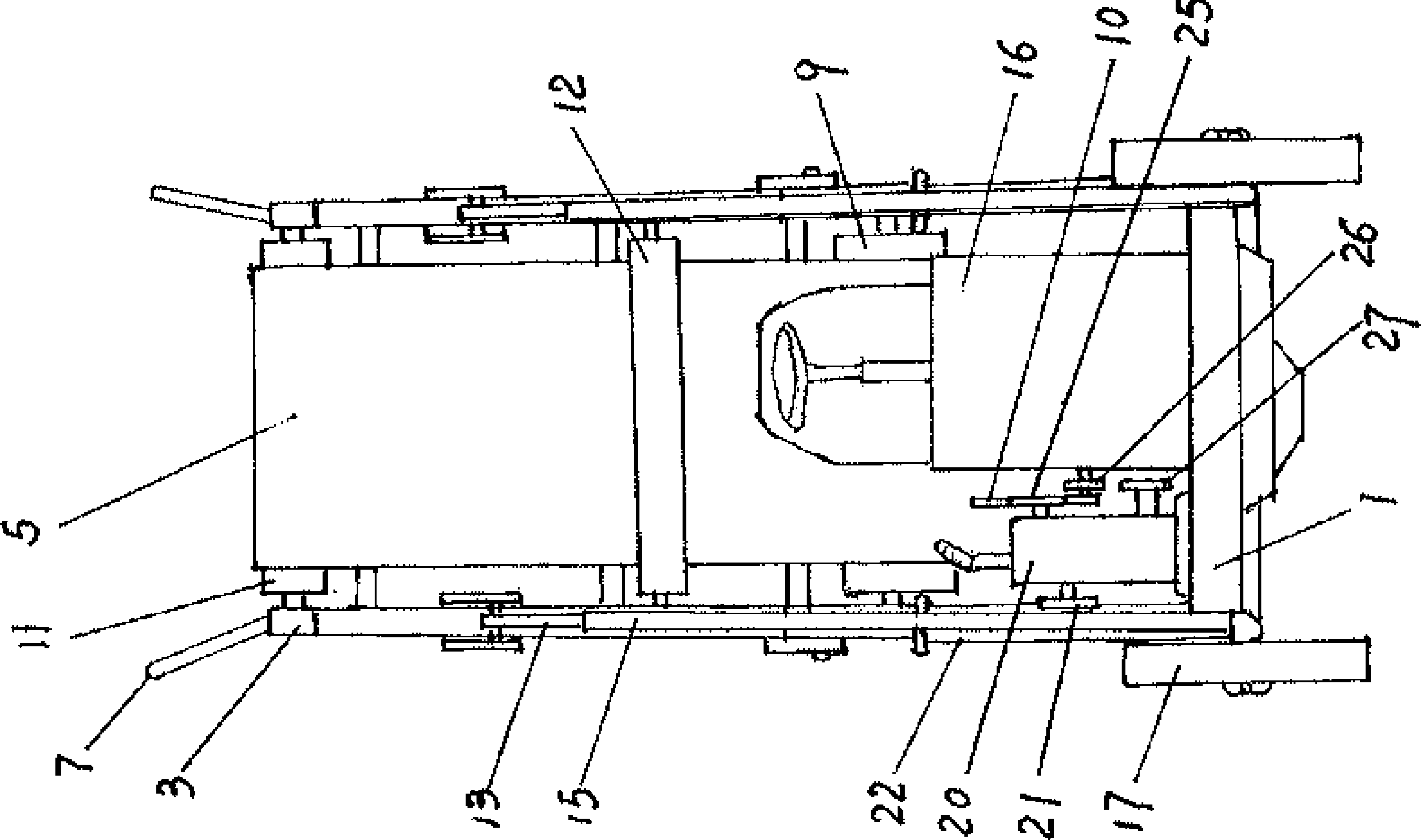

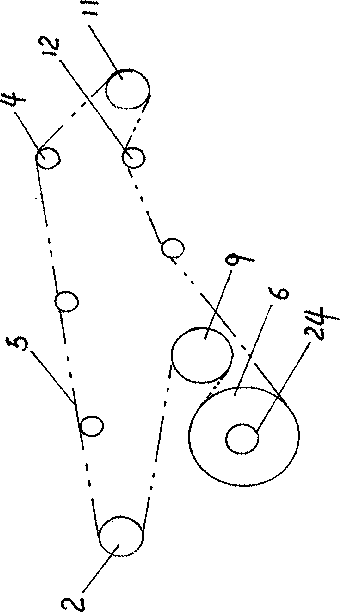

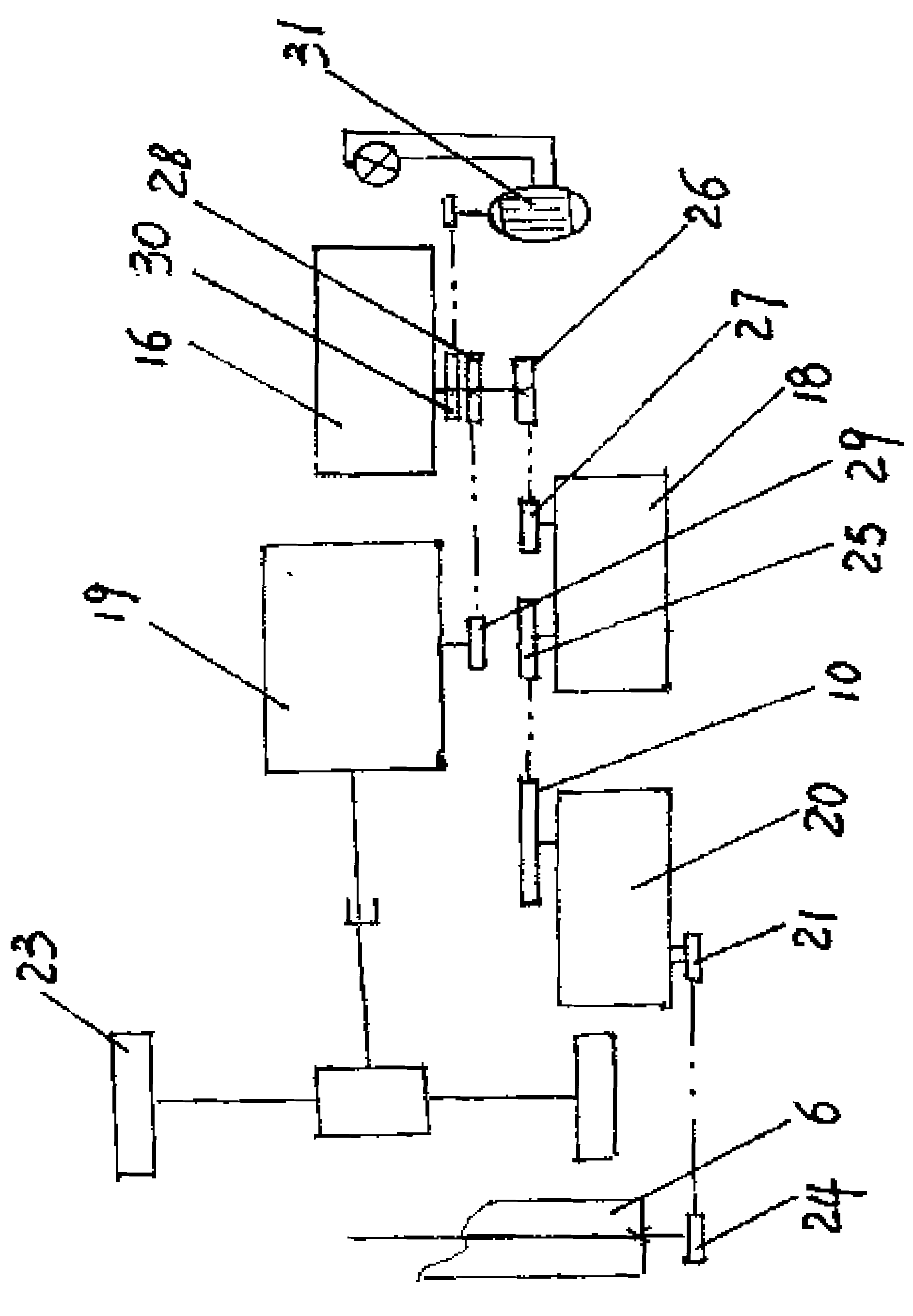

[0024] The following is a detailed description of the vehicle-mounted belt conveyor in conjunction with the accompanying drawings:

[0025] Such as figure 1——As shown in 4: vehicle-mounted belt conveyor, mainly composed of vehicle underframe 1, conveyor belt lower roller 2, conveyor belt frame 3, conveyor belt support roller 4, conveyor belt 5, conveyor belt upper roller 11, and conveyor belt support Roller 12, internal combustion engine 16, front road wheel 17, rear road wheel 23, power generation unit 31, hydraulic system form. The vehicle-mounted belt conveyor is fixed with an internal combustion engine 16, a walking system gearbox 19, a conveyor belt gearbox 20 and a steering wheel and a driver's seat on the upper part of the front of the vehicle chassis 1. The power output wheel of the internal combustion engine 16 is connected to The walking system gearbox 19 links to each other with the conveyor belt gearbox 20, the conveyor belt gearbox power output wheel 21 of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com