Sewage treatment method capable of realizing advanced nitrogen removal through combined biofilm process

A sewage treatment method and deep denitrification technology, applied in the field of advanced sewage treatment, can solve problems such as limitation and insufficient organic carbon source, and achieve the effect of improving utilization rate, weakening dependence, and promoting the process of denitrification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

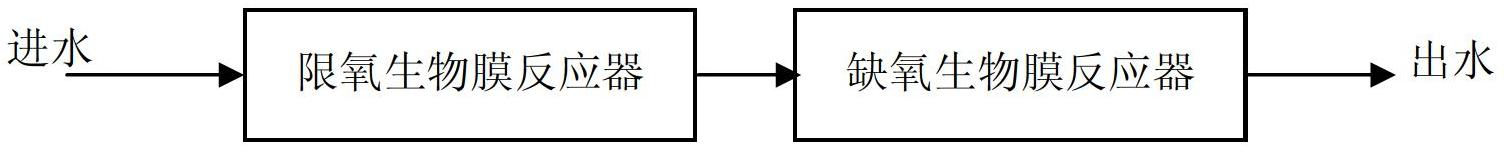

[0029] A sewage treatment method for deep denitrification through a combined biofilm process, the process of which is as follows figure 1 As shown, the treatment mode of oxygen-limited biofilm reactor and anoxic biofilm reactor connected in series is adopted.

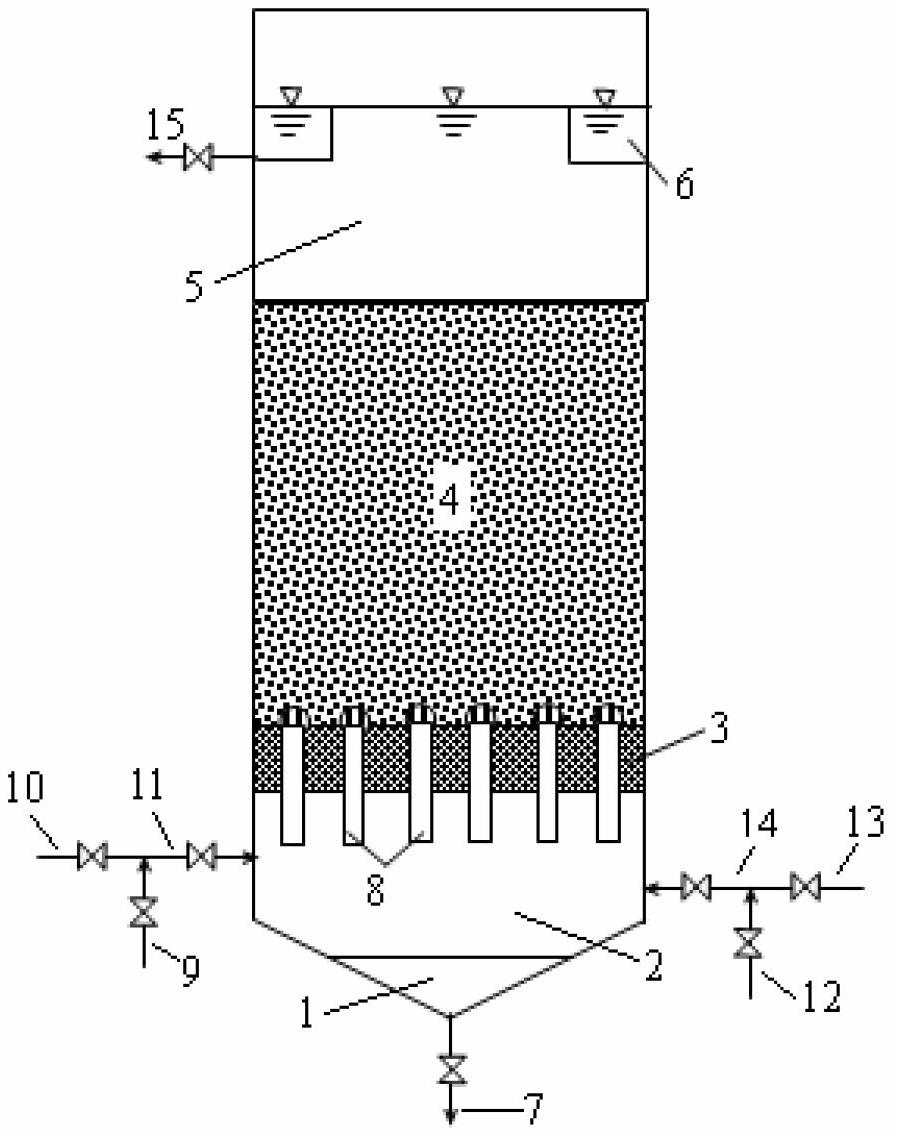

[0030] The structure of the oxygen-limited biofilm reactor is as follows: figure 2 As shown, from bottom to top, there are emptying pipe 7, mud collecting bucket 1, water distribution and air distribution chamber 2, cylindrical filter layer 4, and water outlet area 5; Wherein the water inlet pipe is connected with the filter water inlet pipe 9 and the recoil water inlet pipe 10, and the air inlet pipe is connected with the filter aeration pipe 12 and the recoil air pipe 13; the filter head 8 is arranged on the support layer 3; water pipe15.

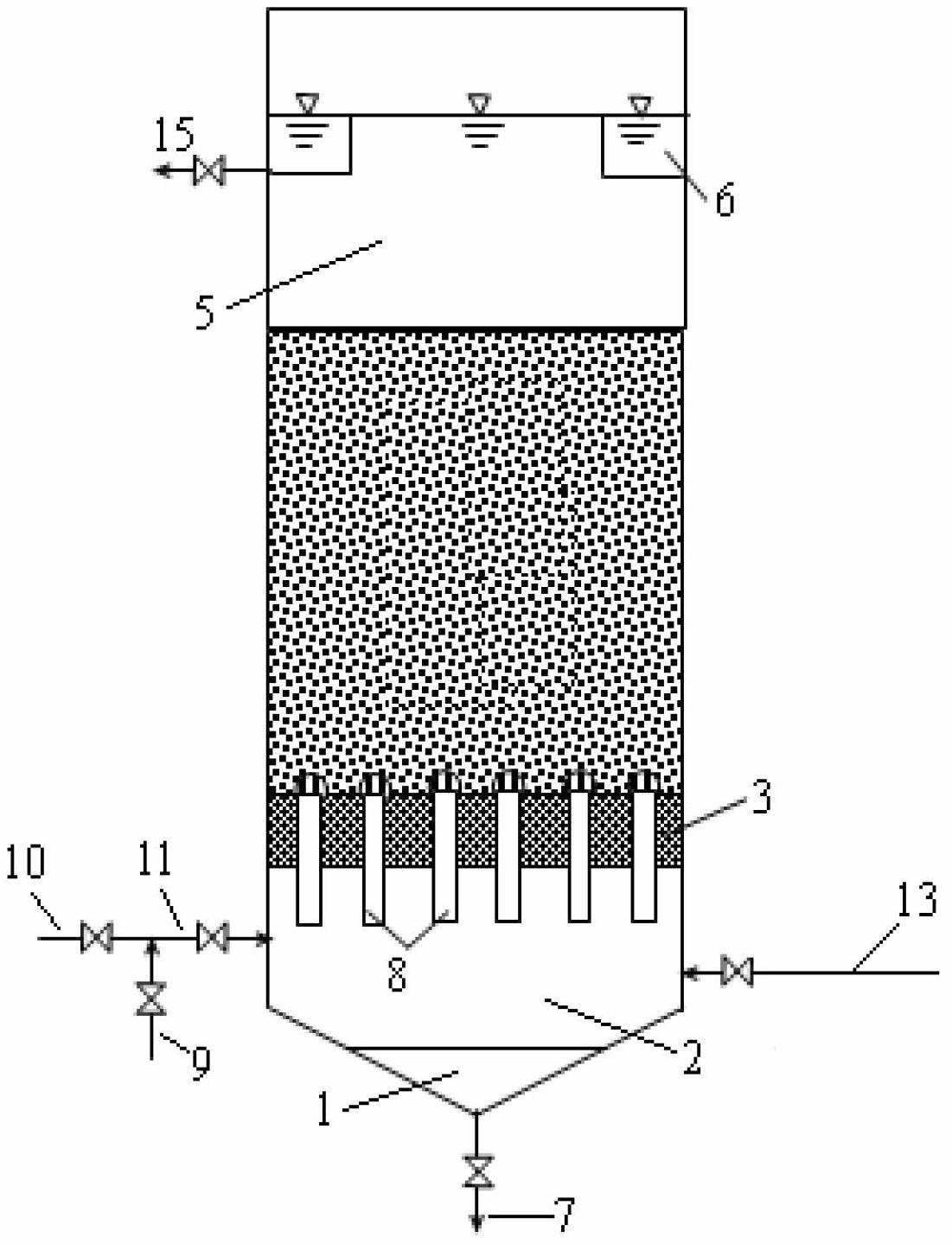

[0031] The structure of the anoxic biofilm reactor is as follows: image 3 As shown, from bottom to top, there are emptying pipe 7, mud collecting bucket 1, water distribution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com