Inlet air pre-heater

A pre-filter, air filter technology, applied in the direction of machine/engine, liquid variable volume machinery, variable volume pump components, etc., can solve the damage of the main engine of the air compressor, reduce the life of the air filter, Problems such as damage to the main engine and ancillary piping systems, to achieve the effect of improving life and ensuring operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below with reference to the drawings and specific embodiments.

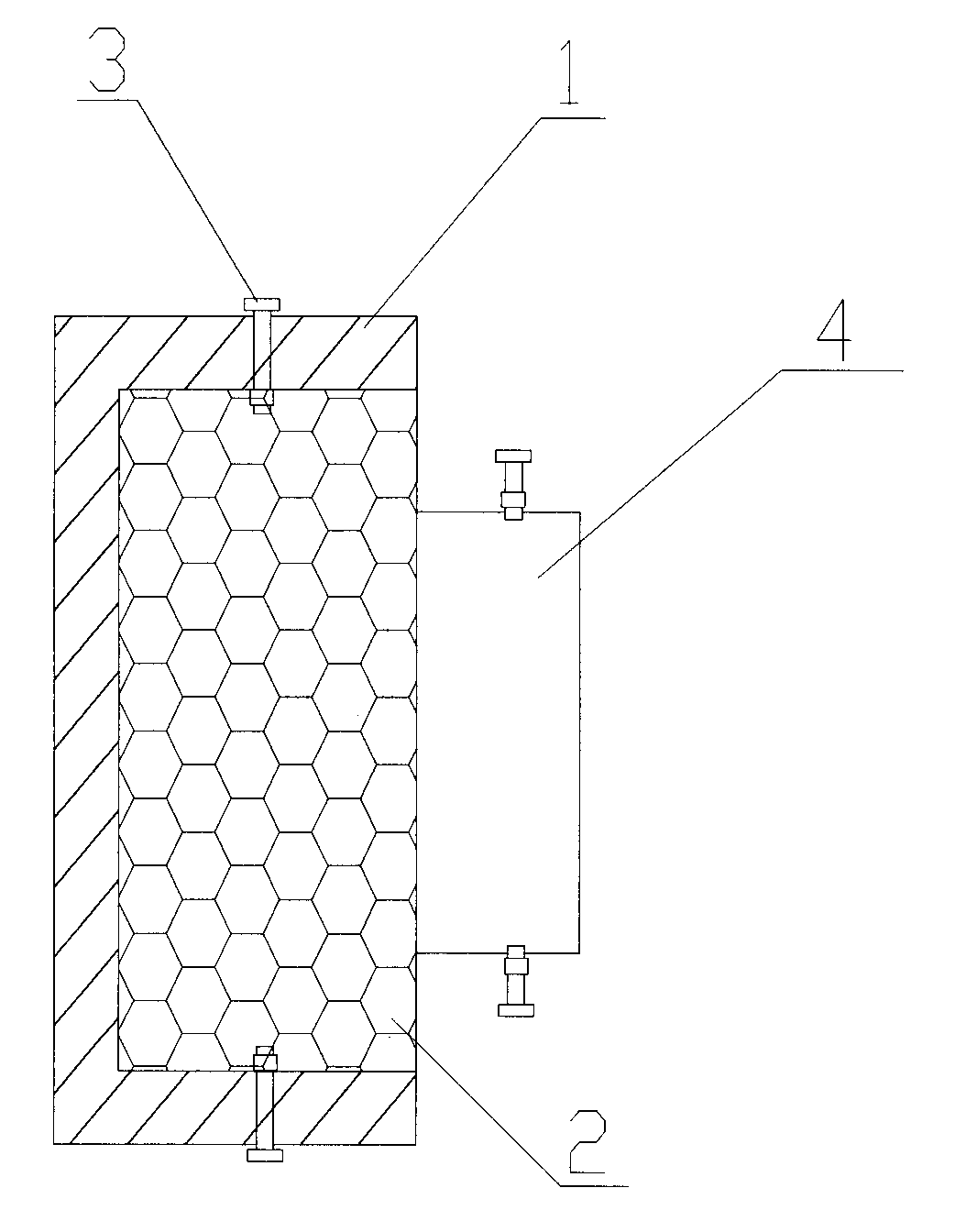

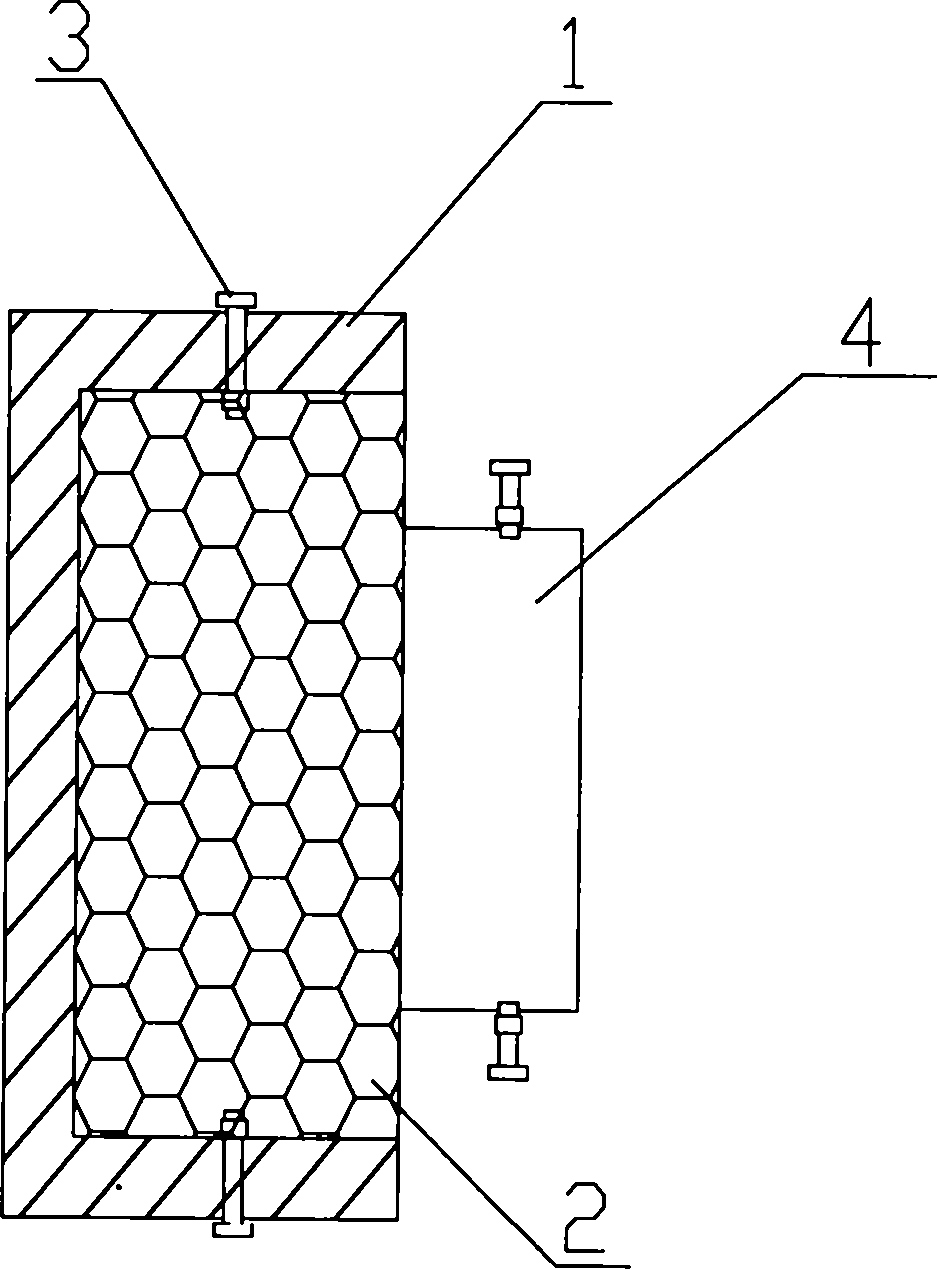

[0010] As shown in the figure, the air intake pre-filter is connected to the front end of the air filter, and includes the filter material 1, the housing 2, the fixing part 3, and the connection part 4. The housing 2 has a hole-like structure, which facilitates air circulation, and the air outlet The end is connected with the air filter through the connecting piece 4, so that the pre-filtered air enters the air filter for secondary filtration, and the filter material 1 is wrapped around the air inlet end and the periphery of the housing 2. The present invention is arranged at the front end of the original air filter and is connected with the air filter by a connecting piece. The filter material coated on the outer end of the casing can pre-filter the large particles of impurities in the air, and can increase the air pressure. The life of the air filter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com