Pipe joint

A technology for pipe joints and connecting pipes, applied in the field of pipe joints, can solve the problems of many constraints, unable to obtain the sealing effect of sealing rings, etc., and achieve the effect of easy elastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0140] Hereinafter, an in-line pipe joint according to an embodiment of the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited to the Example shown below, Various changes are possible in the range which does not deviate from the technical idea of this invention.

[0141] 【Example】

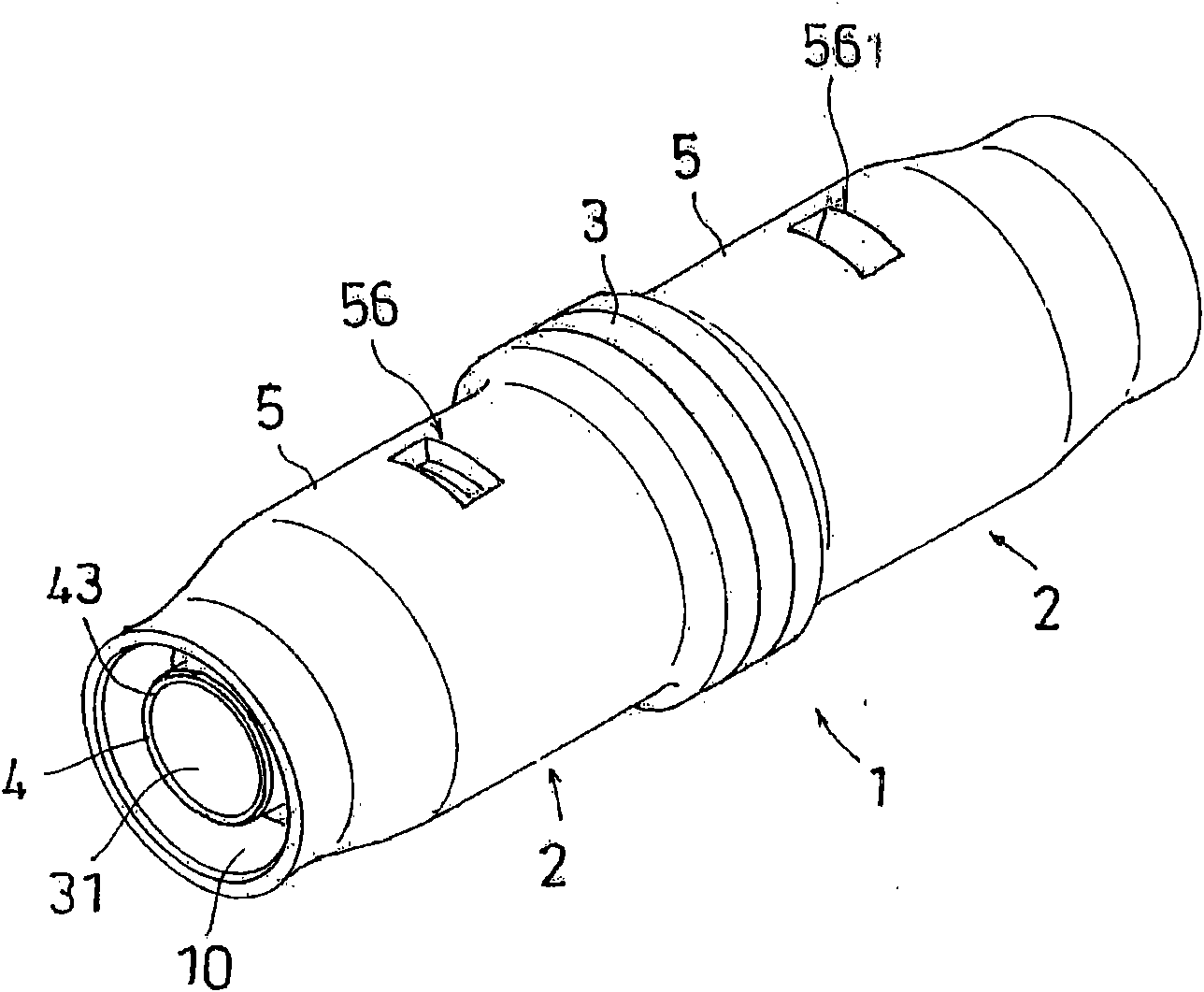

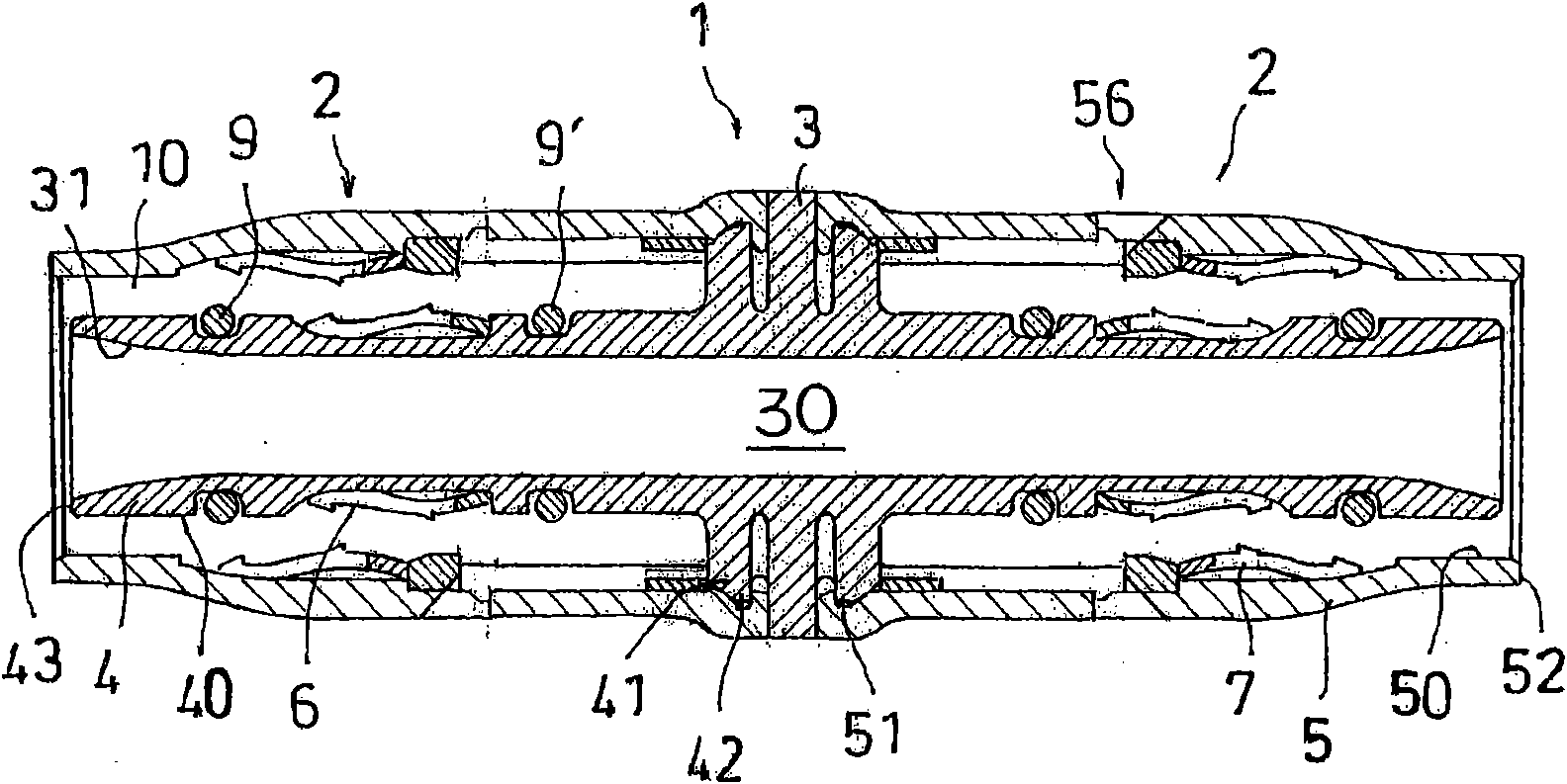

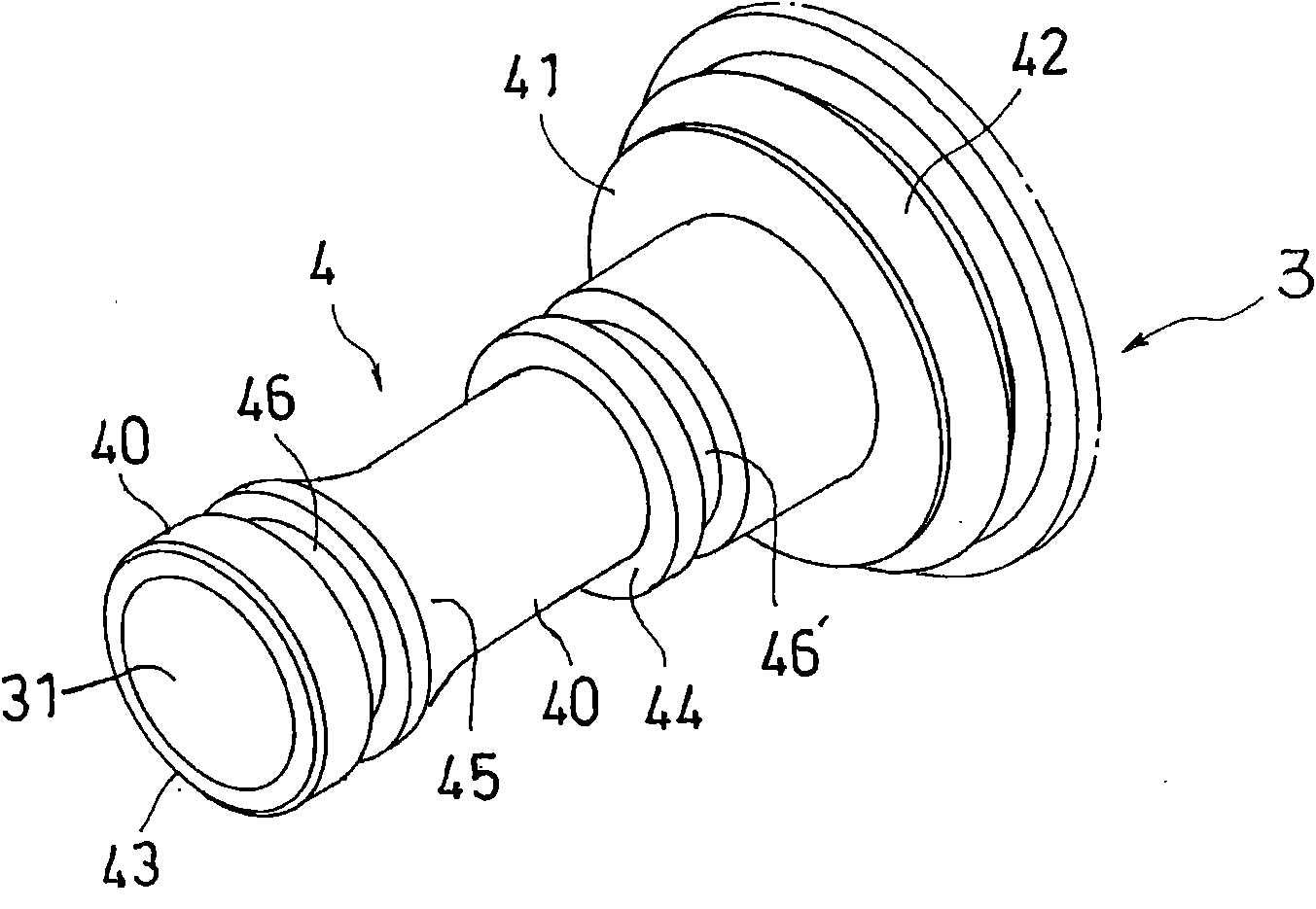

[0142] figure 1 It is a perspective view showing the whole of the in-line pipe fitting 1 according to a preferred embodiment of the present invention. refer to figure 1 It can be seen that the pipe joint 1 of the present invention has two connecting pipe insertion sockets 2 on the I-shape. However, the pipe joint of the present invention is not limited to the type having two connecting pipe insertion sockets 2, and the pipe joint of the present invention also includes, for example, arranging the connecting pipe insertion socket 2 of the present invention on only one side and disposing the connecting pipe insertion socket 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com