Water film evaporative condenser vacuum tube box

A vacuum tube box and condenser technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of cracked welds, increased back pressure of steam turbines, decreased vacuum degree, etc., to enhance resistance to external pressure. ability, the effect of reducing the span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is implemented like this:

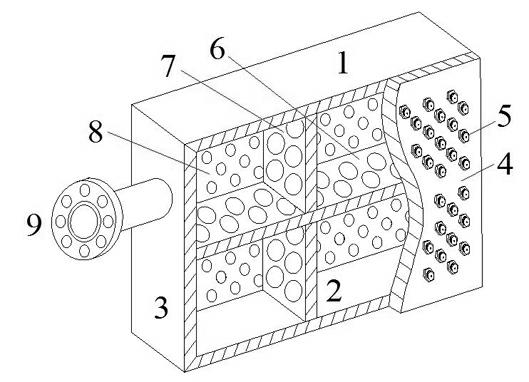

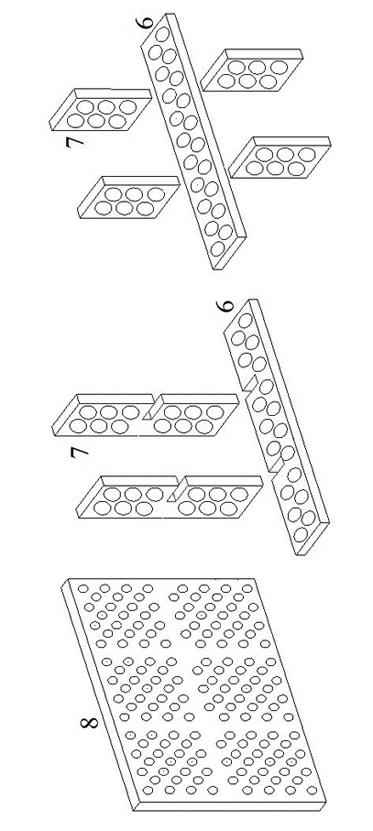

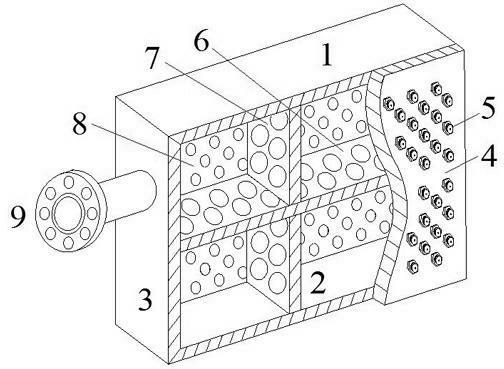

[0031] exist figure 1 Among them, along the height direction of the tube box, a horizontal support plate is installed to divide a large span in the height direction into two small spans. Such as figure 2 As shown, along the width direction of the tube box, two vertical support plates divide one large span in the horizontal direction into three small spans. The horizontal and vertical spans of the pipe box are reduced, and the ability of the pipe box top plate, bottom plate and side plate to resist external pressure is enhanced.

[0032] Such as figure 1 As shown, the horizontal support plate and the vertical support plate are in x The end face of the direction should be welded on the tube sheet and supported on the cover plate, so that the horizontal span and vertical span of the tube sheet and cover plate are also reduced, so the compressive capacity of the tube sheet and cover plate is also enhanced.

[0033] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com