Liquid crystal display device, array substrate thereof and manufacturing method

A technology of liquid crystal display devices and array substrates, applied in the manufacture of array substrates and array substrates, and in the field of liquid crystal display devices, can solve the problems of waste, slow response rate of liquid crystal molecules, and failure of normal deflection and alignment of liquid crystal molecules, etc., to reduce the cost of defective products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

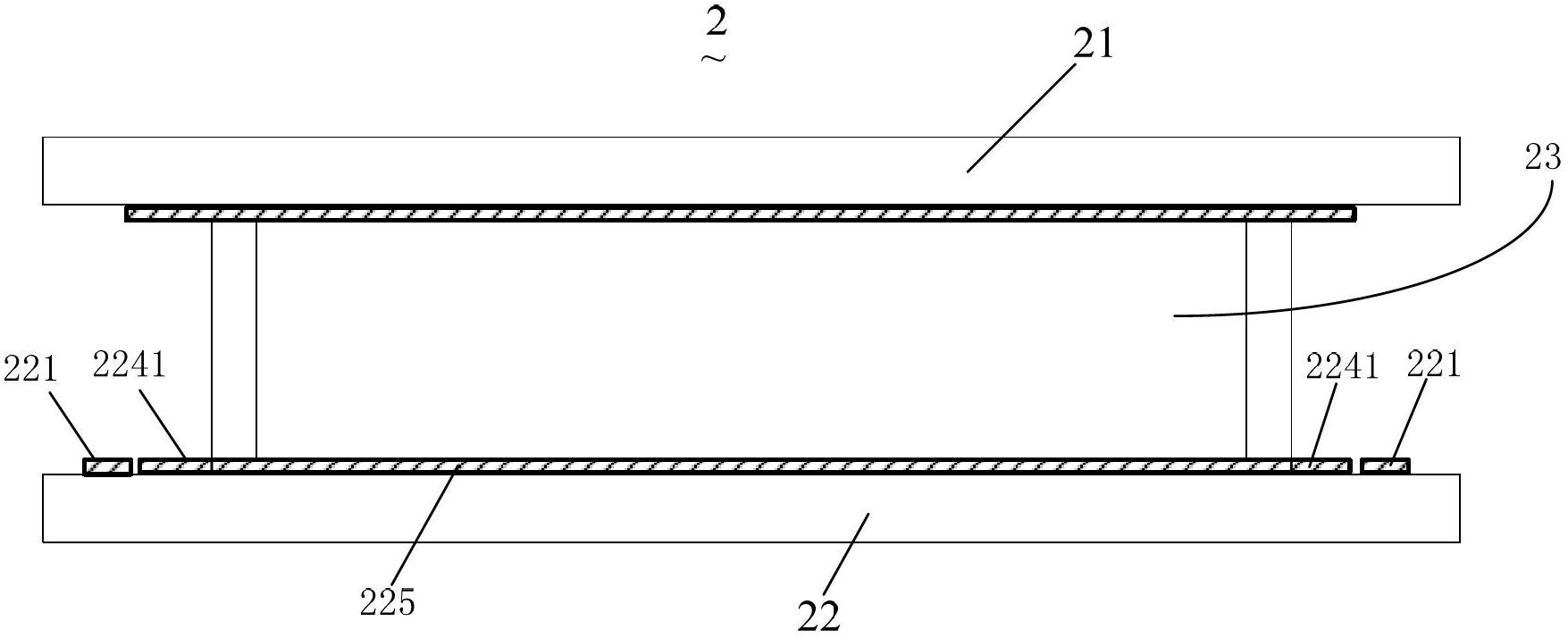

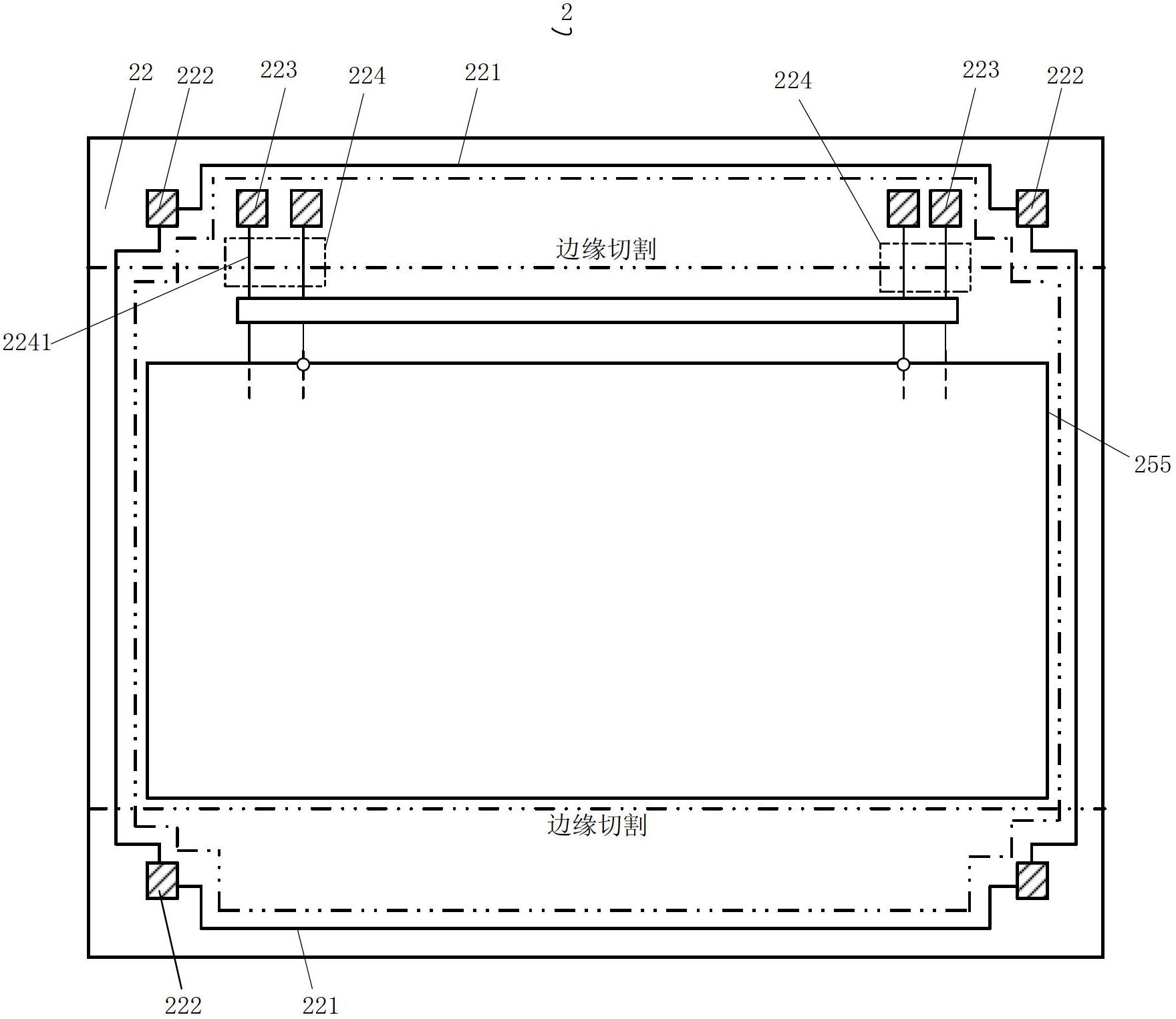

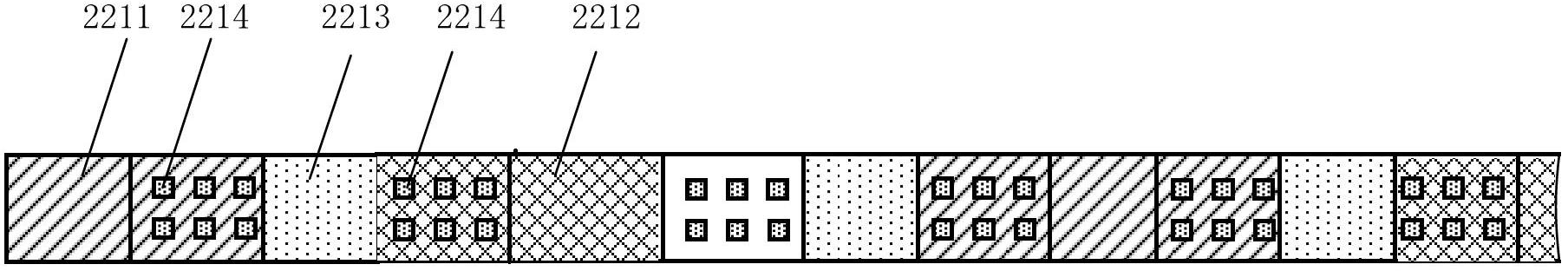

[0024] see figure 1 , figure 2 as well as image 3 , figure 1 is a schematic structural diagram of a liquid crystal display device in an embodiment of the present invention; figure 2 yes figure 1 A schematic diagram of the connection relationship of each line of the array substrate in the shown liquid crystal display device; image 3 yes figure 1 A schematic diagram of the connection relationship of each part of the reference line shown.

[0025] The liquid crystal display device 2 includes: a color filter substrate 21 , an array substrate 22 and a liquid crystal layer 23 sandwiched between the array substrate 22 and the color filter substrate 21 . The array substrate 22 includes a reference circuit 221 , a first test pad 222 , a second test pad 223 , an auxiliary circuit 224 and a semiconductor array circuit 225 . The semiconductor arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com