Discharge lamp with external tube

A technology for discharge lamps and outer tubes, which is applied in the direction of discharge lamps, discharge tubes, gas discharge lamp parts, etc., can solve the problems of coating material costs, achieve sufficient bonding strength, increase the bonding area, and realize The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

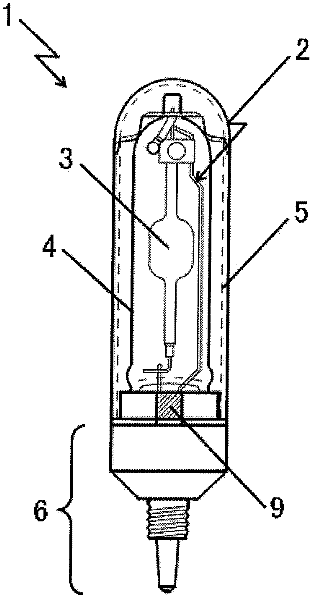

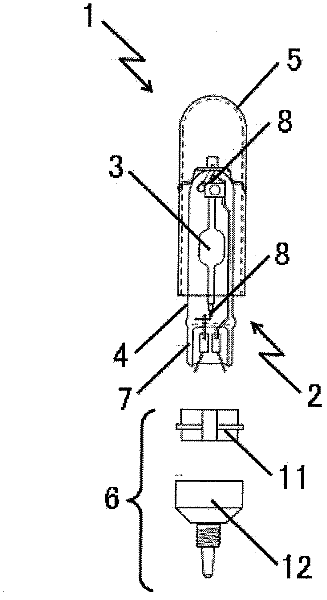

[0023] figure 1 and figure 2 It is a figure which shows the discharge lamp of this invention. Such as figure 1 As shown, the discharge lamp 1 is inside a sealed inner tube 4 made of glass, and a lamp main body 2 accommodating an arc tube 3 such as a ceramic metal halide lamp is attached to a base 6 . The outer tube 5 is bonded to the lamp cap 6 in such a way as to accommodate the lamp main body 2 .

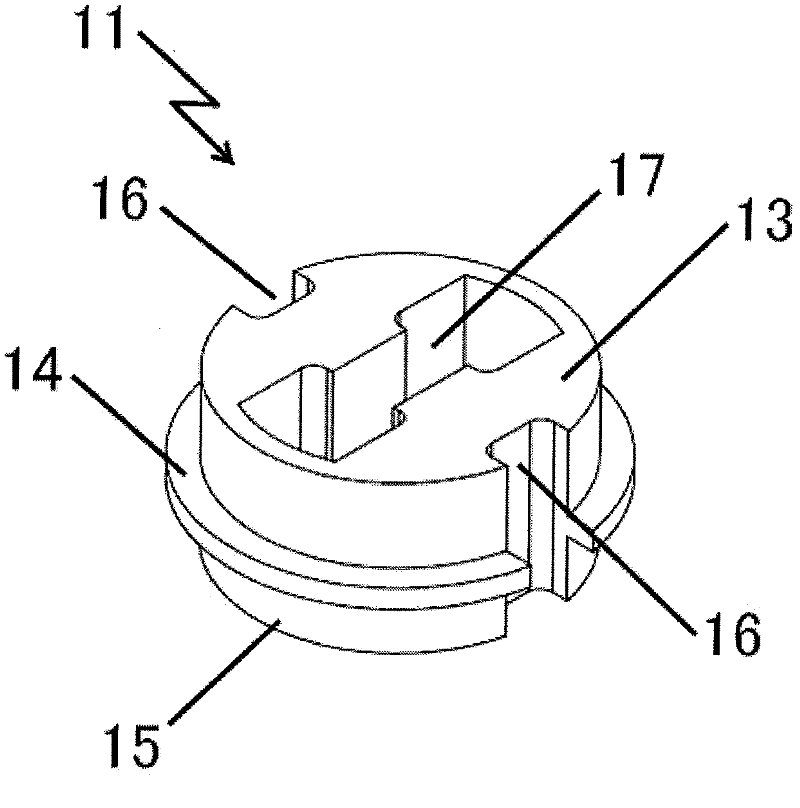

[0024] One end of the lamp main body 2 is sealed, and the other end forms an extrusion sealing portion 7 . A pair of lead wires 8 of the arc tube 3 are led out from the extruded sealing portion 7 to the outside of the lamp main body. The lead wire 8 derived is connected with the lamp cap 6 . By supplying power to the wire 8 from the outside, the luminous tube 3 lights up. The lamp cap 6 is composed of a mounting part 11 and a lamp cap main body 12 . After the lamp main body 2 and the outer tube 5 are installed on the installation part 11, the lamp main body 2 and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com