Patch and patch preparation

A preparation and patch technology, which is applied in the direction of film/sheet adhesives, adhesives, sheet conveying, etc., can solve problems such as detachment, and achieve sufficient bonding strength, limited movement inhibition, and good adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

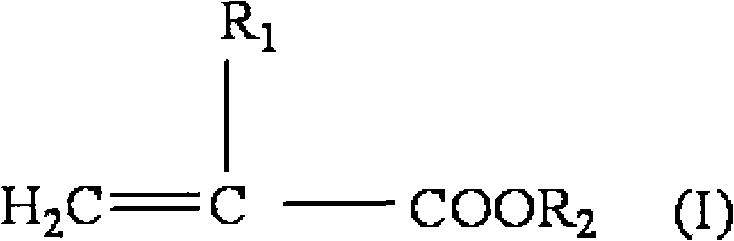

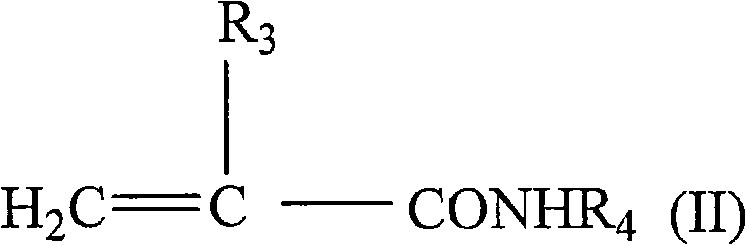

[0072] [Example 1] patch

[0073] (1) First, 70 parts by weight of 2-ethylhexyl acrylate (hereinafter may be referred to as "2-EHA") as monomer (a), 10 parts by weight of N-hydroxyethyl propylene as monomer (b) Amide (hereinafter may be referred to as "HEAA"), 20 parts by weight of N-vinyl-2-pyrrolidone (hereinafter may be referred to as "N-VP") as monomer (c), and 333.3 parts by weight of acetic acid as solvent Ethyl ester was charged into a reaction vessel equipped with a cooling tube, nitrogen guide tube, thermometer, dropping funnel, and stirrer, and then the contents were stirred at room temperature for 1 hour while nitrogen bubbling (100 mL / min). After that, the contents in the reaction vessel were heated, and when the temperature of the contents reached 60° C., 0.2 parts by weight of 2,2′-azobisisobutyronitrile (AIBN) was added as a polymerization initiator. The temperature of the contents was controlled so as to be kept at 60° C., and then polymerization was performed...

Embodiment 2

[0076] [Example 2] patch

[0077] Use 50 parts by weight of 2-ethylhexyl acrylate as monomer (a), 10 parts by weight of N-hydroxyethylacrylamide as monomer (b) and 40 parts by weight of N-vinyl-2-pyrrolidone as Except for the monomer (c), an acrylic copolymer (2-EHA / HEAA / N-VP=50 / 10 / 40) was obtained in the same manner as in Example 1. A composition for forming an adhesive layer was prepared from an acrylic copolymer in the same manner as in Example 1, and then a patch was prepared.

Embodiment 3

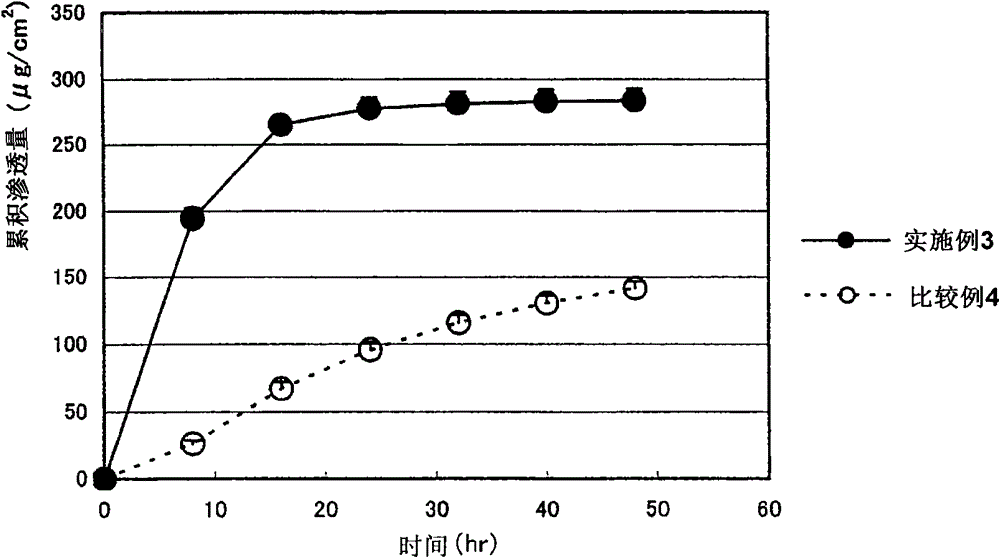

[0112] [Example 3] patch preparation

[0113] (1) Pramipexole as a drug was added to the acrylic copolymer solution used in the preparation of the patch of Example 1 in an amount of 5.3 parts by weight relative to 100 parts by weight (solid content) of the acrylic copolymer. Further, isopropyl palmitate (IPP), as an organic liquid component, was added to the mixture in an amount of 72.7 parts by weight relative to 100 parts by weight (solid content) of the acrylic copolymer. Thus, a composition for forming an adhesive layer was prepared. It should be noted that pramipexole has one primary and one secondary amino group in its molecule as shown in formula (III) below.

[0114]

[0115] (2) apply the above-mentioned composition for forming an adhesive layer on the release surface of a release liner made of a polyethylene terephthalate (PET) film having a thickness of 75 μm with an applicator, It was then dried at 80° C. for 5 minutes. After that, a PET film having a thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com