Anisotropic Conductive Film

An anisotropic, conductive film technology, used in conductive connections, conductive adhesives, conductive adhesive connections, etc., can solve problems such as reduced adhesion, inability to remove moisture from anisotropic conductive films, and inability to eliminate them. The effect of low on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

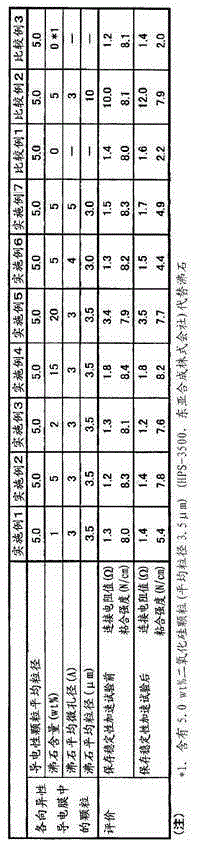

[0039] Zeolite having an effective pore diameter of 3 angstroms (Zeorum A-3, manufactured by Tosoh Co., Ltd.) was dried under reduced pressure to volatilize water, and then pulverized and classified with a sieve. The average particle diameter of the obtained zeolite particles was 3.5 μm.

[0040] The anisotropic conductive films of Examples 1 to 5 were prepared in the same manner as in Comparative Example 1, except that the zeolite particles were added to the insulating binder in the proportion shown in Table 1.

Embodiment 6

[0042] Zeolite having an effective pore diameter of 4 angstroms (Zeorum A-4, manufactured by Tosoh Co., Ltd.) was dried under reduced pressure to volatilize water, pulverized, and classified with a sieve to prepare zeolite particles having an average particle diameter of 3.0 μm.

[0043] The anisotropic conductive film of Example 6 was prepared in the same manner as in Comparative Example 1, except that the zeolite particles were added to the insulating binder in the proportion shown in Table 1.

Embodiment 7

[0045] Zeolite with an effective pore diameter of 5 angstroms (Zeorum A-5, manufactured by Tosoh Co., Ltd.) was dried under reduced pressure to evaporate water, crushed, and classified with a sieve to prepare zeolite particles with an average particle diameter of 3.0 μm.

[0046] The anisotropic conductive film of Example 7 was prepared in the same manner as in Comparative Example 1, except that the zeolite particles were added to the insulating binder in the ratio shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com