Blueberry dry powder and method for preparing blueberry dry powder through freeze drying technology

A technology of blueberry fruit and dry powder, which is applied in the direction of food preparation, application, food science, etc., and can solve the problems that the preparation process of blueberry fruit dry powder has not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

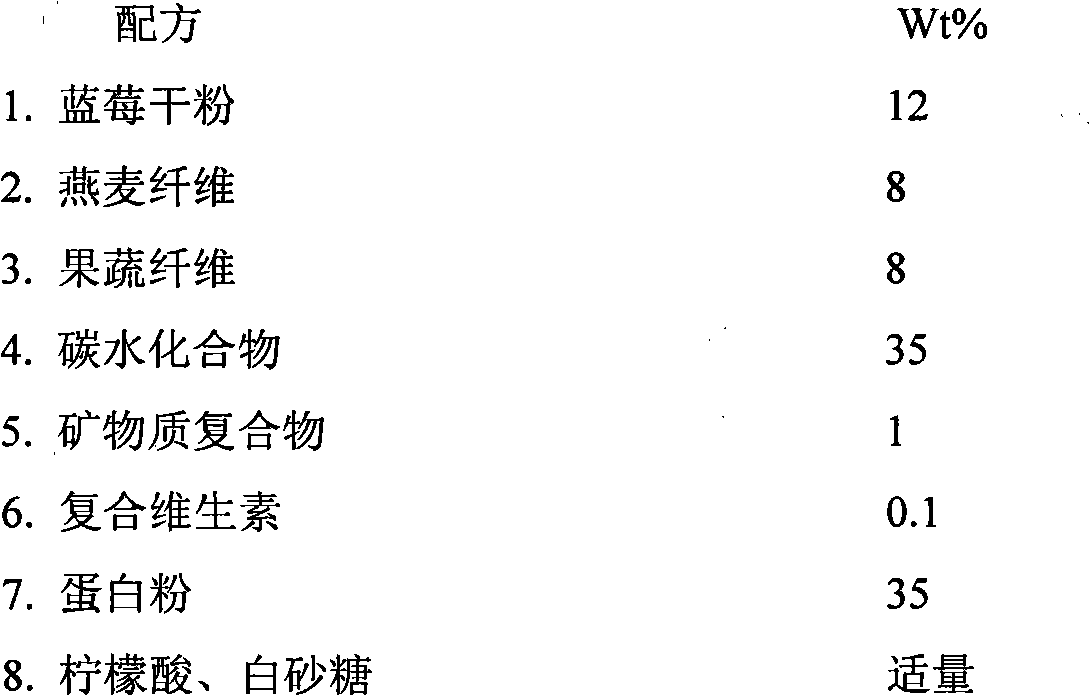

Image

Examples

Embodiment 1

[0048] Embodiment 1. prepare Duke's blueberry fruit dry powder

[0049] Use an automatic cleaning machine to clean the picked fresh blueberries of the Duke variety until there is no dirt residue, and then use a homogenizer to crush the blueberries into a uniform and fine mud to obtain blueberry puree; accurately weigh 50g of maltodextrin powder, add 400mL of distilled water to completely dissolve the maltodextrin to obtain a maltodextrin solution; weigh 300g of blueberry puree, measure 250mL of maltodextrin solution, and put the blueberry puree and maltodextrin solution in a homogenizer Mix and homogenize in medium for 10 minutes to obtain the blueberry puree sample containing carrier; The surface glass of the puree sample was sealed with plastic wrap, and placed in a -40°C refrigerator for pre-freezing for 6 hours to obtain a pre-frozen sample of the blueberry puree before freeze-drying; the pre-frozen sample was taken out of the -40°C refrigerator, and sealed with Remove th...

Embodiment 2

[0051] Embodiment 2. Preparation of Duke's blueberry fruit dry powder

[0052] Use an automatic cleaning machine to clean the picked fresh blueberries of the Duke variety until there is no dirt residue, and then use a homogenizer to crush the blueberries into a uniform and fine mud to obtain blueberry puree; accurately weigh 50g of maltodextrin powder, add 400mL of distilled water to completely dissolve the maltodextrin to obtain a maltodextrin solution; weigh 300g of blueberry puree, measure 150mL of maltodextrin solution, and put the blueberry puree and maltodextrin solution in a homogenizer Mix and homogenize in medium for 10 minutes to obtain the blueberry puree sample containing carrier; The surface glass of the puree sample was sealed with plastic wrap, and placed in a -40°C refrigerator for pre-freezing for 6 hours to obtain a pre-frozen sample of the blueberry puree before freeze-drying; the pre-frozen sample was taken out of the -40°C refrigerator, and sealed with Re...

Embodiment 3

[0054] Embodiment 3. Preparation of Duke's blueberry fruit dry powder

[0055] Use an automatic cleaning machine to clean the picked fresh blueberries of the Duke variety until there is no dirt residue, and then use a homogenizer to crush the blueberries into a uniform and fine mud to obtain blueberry puree; accurately weigh 50g of maltodextrin powder, add 400mL of distilled water to completely dissolve the maltodextrin to obtain a maltodextrin solution; weigh 200g of blueberry puree, measure 400mL of maltodextrin solution, and put the blueberry puree and maltodextrin solution in a homogenizer Mix and homogenize in medium for 10 minutes to obtain the blueberry puree sample containing the carrier; The watch glass of the puree sample was sealed with plastic wrap, and placed in a -40°C refrigerator for pre-freezing for 6 hours to obtain a pre-frozen sample of the blueberry puree before freeze-drying; the pre-frozen sample was taken out of the -40°C refrigerator, and sealed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com