Vermicelli processing device and method

A processing device and vermicelli technology, applied in application, food preparation, food science, etc., can solve problems such as restricting the development of vermicelli processing industry, low efficiency, high energy consumption, etc., and achieve easy and convenient cleaning and debugging, and fast drying speed , The effect of high-quality finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The vermicelli processing device and method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

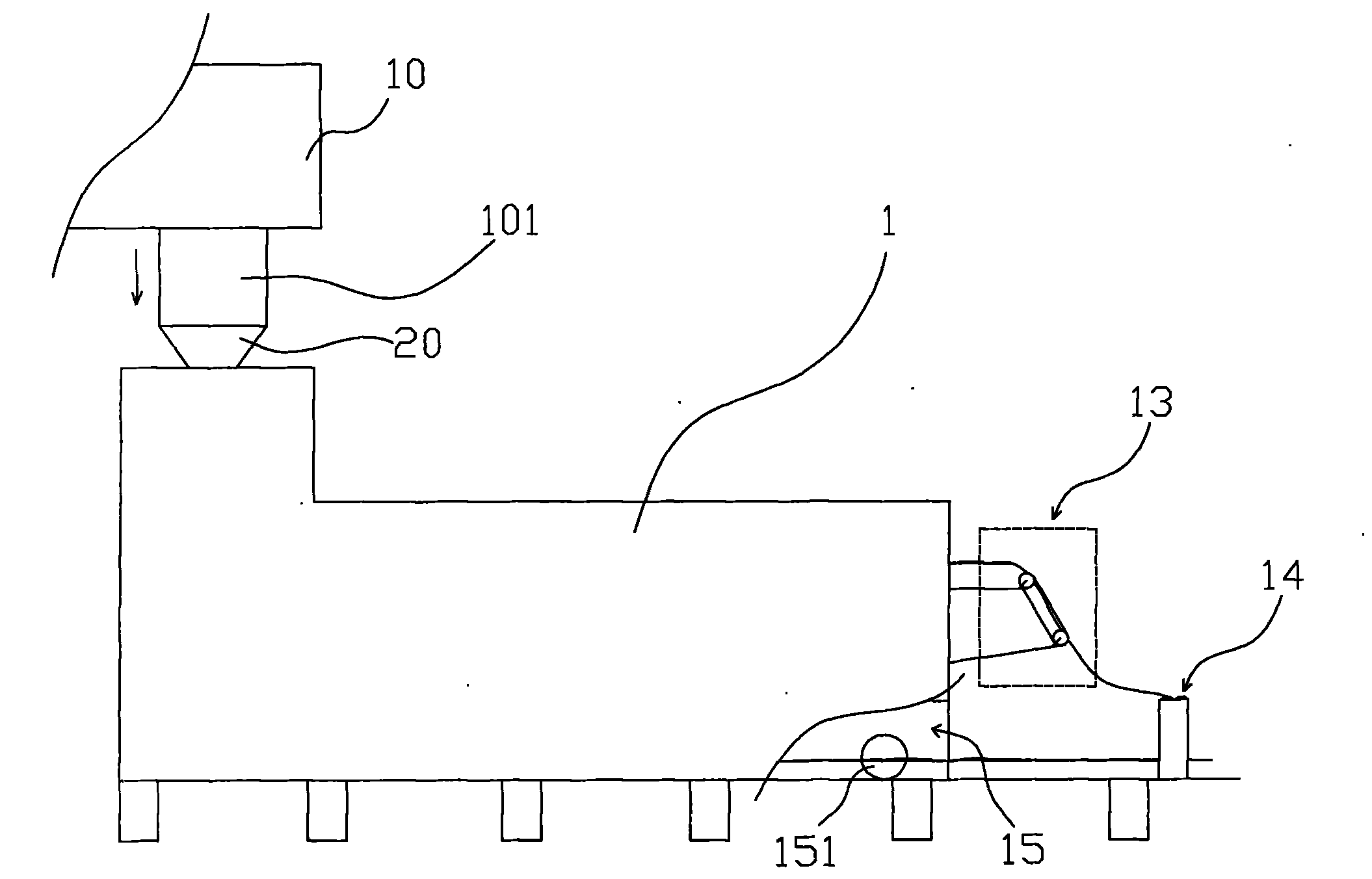

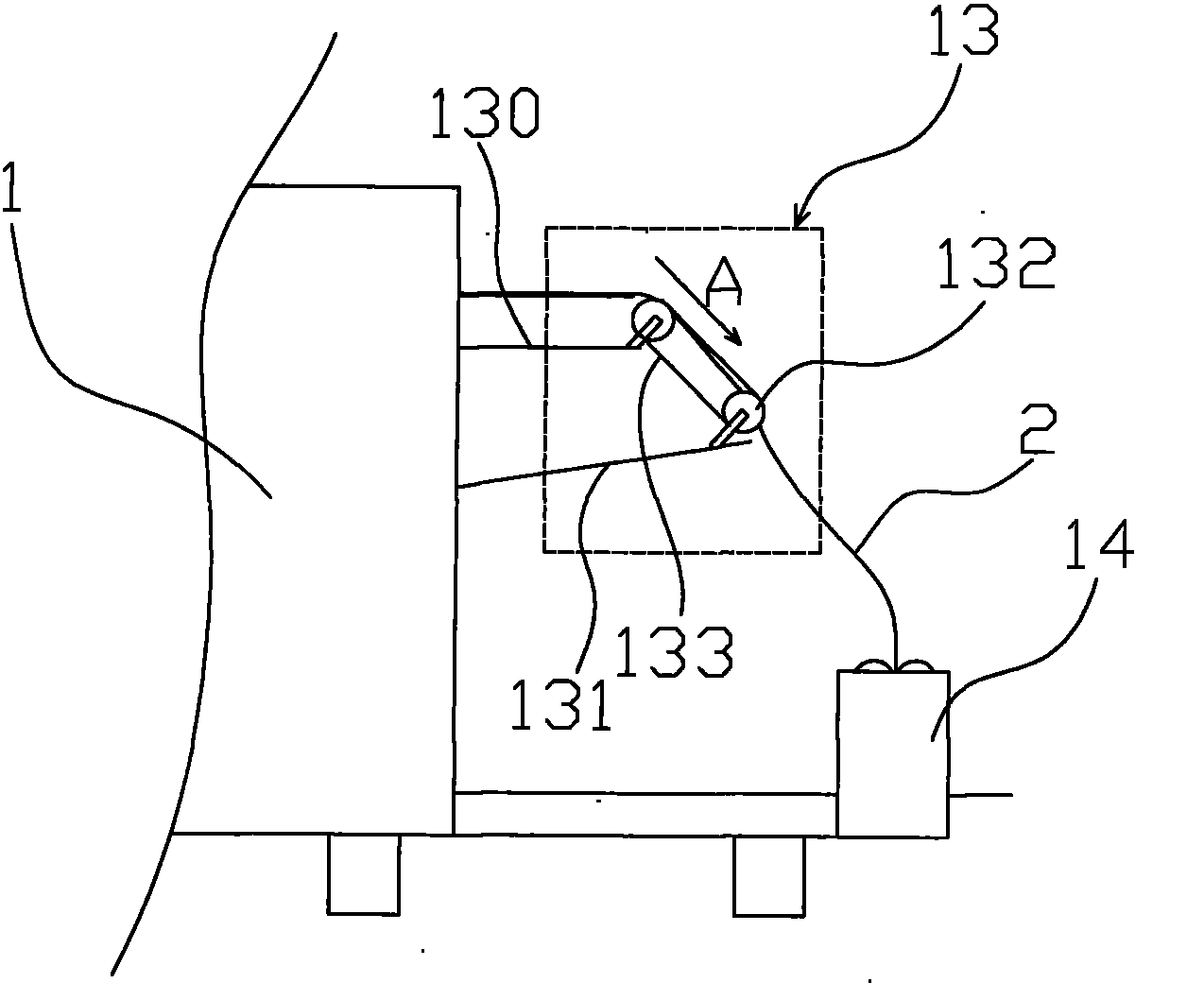

[0035] refer to Figure 1~6 As shown in , the vermicelli processing device 1 of the present invention includes a feeding chamber 10, a slurry mixing device 11, a strip-shaped vermicelli continuous molding device (not shown in the figure) and a bar making device (not shown in the figure).

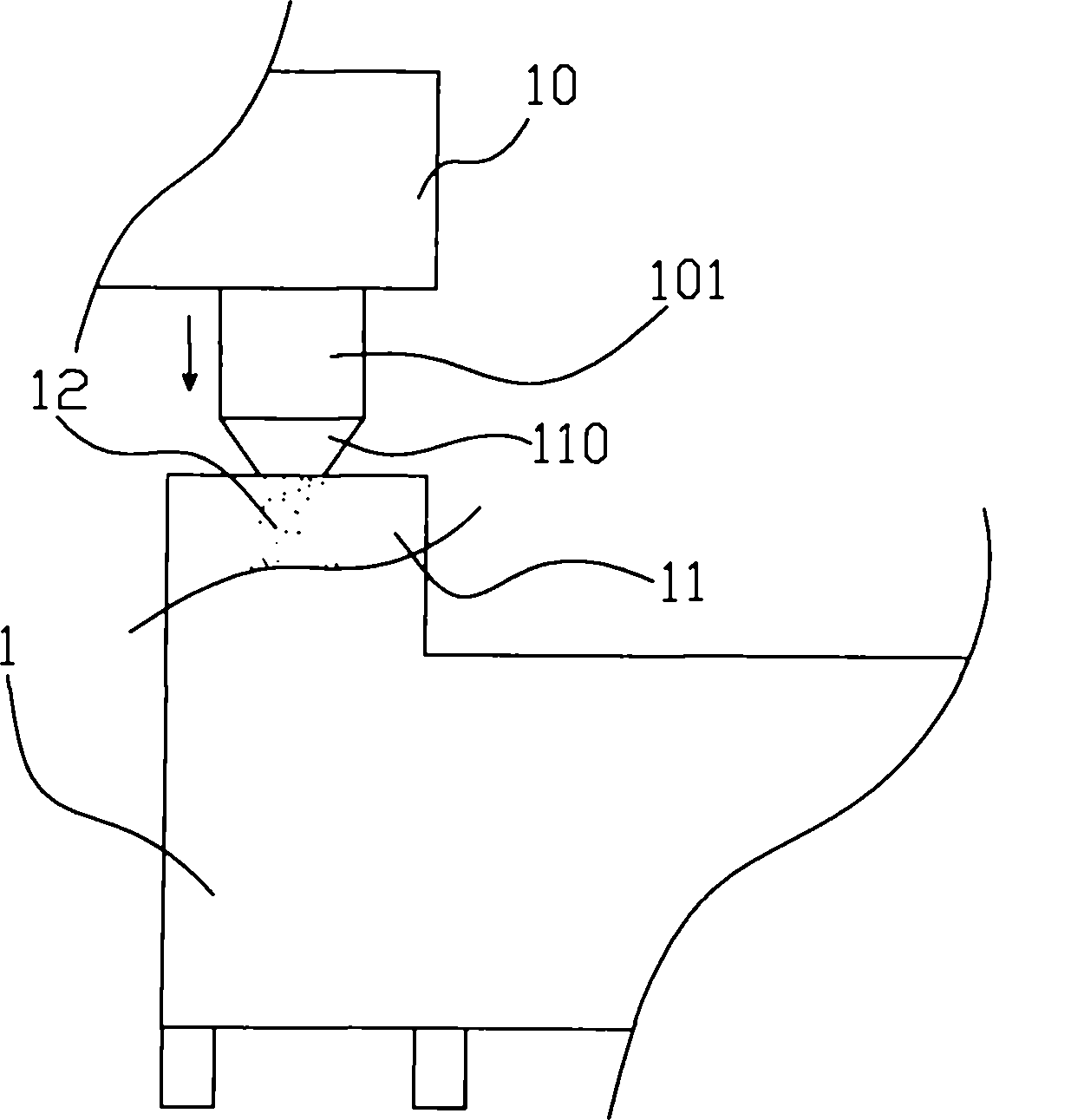

[0036] See figure 2 , the feeding chamber 10 is erected above the slurry mixing device 11, and a feeding funnel 110 is provided on the mixing device 11 and facing the feeding chamber 10, and the raw material 12 passes through the feeding funnel 110 under its own gravity Fall into the slurry mixing device 11.

[0037] In addition, in order to facilitate smooth feeding without leakage of raw materials, a feeding cylinder 101 sealingly connected with the feeding funnel 110 is also provided at the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com