Electric pressure cooker with full-automatic pressure regulation and full-automatic pressure regulation method thereof

An electric pressure cooker and automatic pressure regulation technology, applied in pressure cookers and other directions, can solve the problems of high cost, complicated installation, unfavorable popularization of electric pressure cookers, etc., and achieve the effect of simple operation, convenient use, and favorable for popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

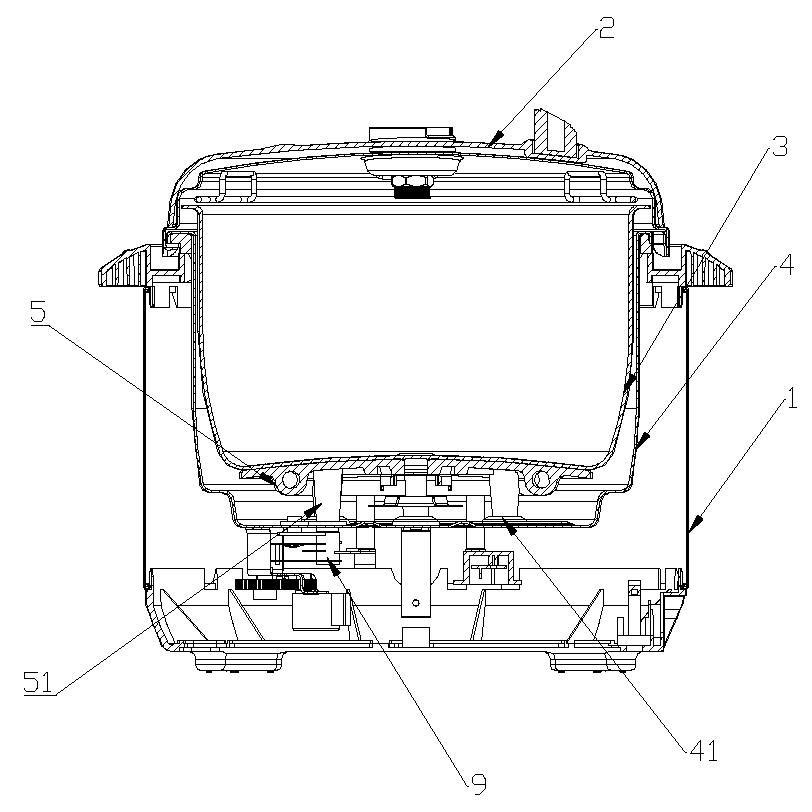

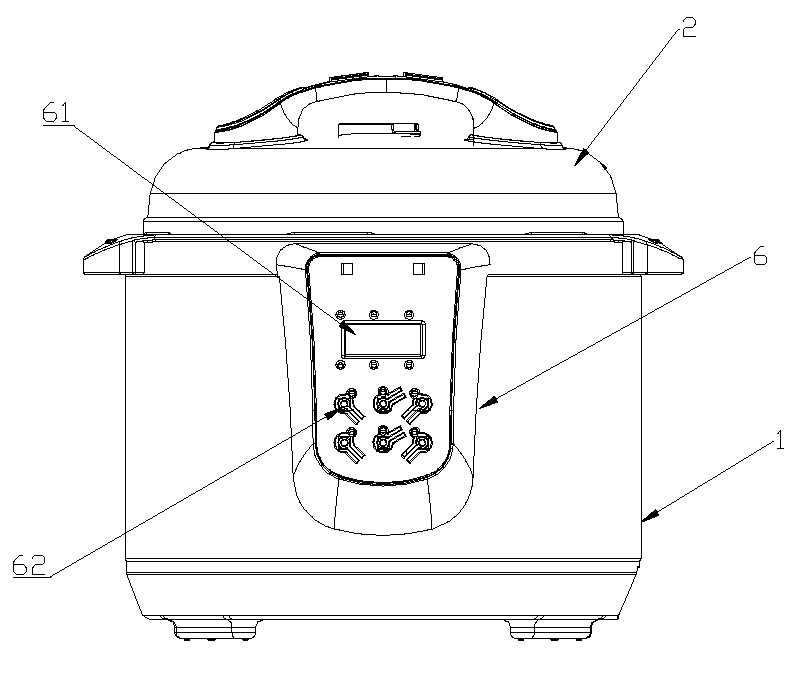

[0049] Embodiment 1 of an electric pressure cooker with fully automatic pressure regulation of the present invention is as follows: Figure 1 to Figure 6 As shown, it includes a casing 1, a pot cover 2, an outer pot 4, an inner pot 3 and a heating plate 5, the bottom of the outer pot 4 is provided with an elastic support device, the casing 1 is provided with a control panel 6, and the control panel 6 is controlled by a display screen 61 Composed of control buttons 62, the electric pressure cooker also includes:

[0050] A functional control unit, which is arranged on the control panel 6;

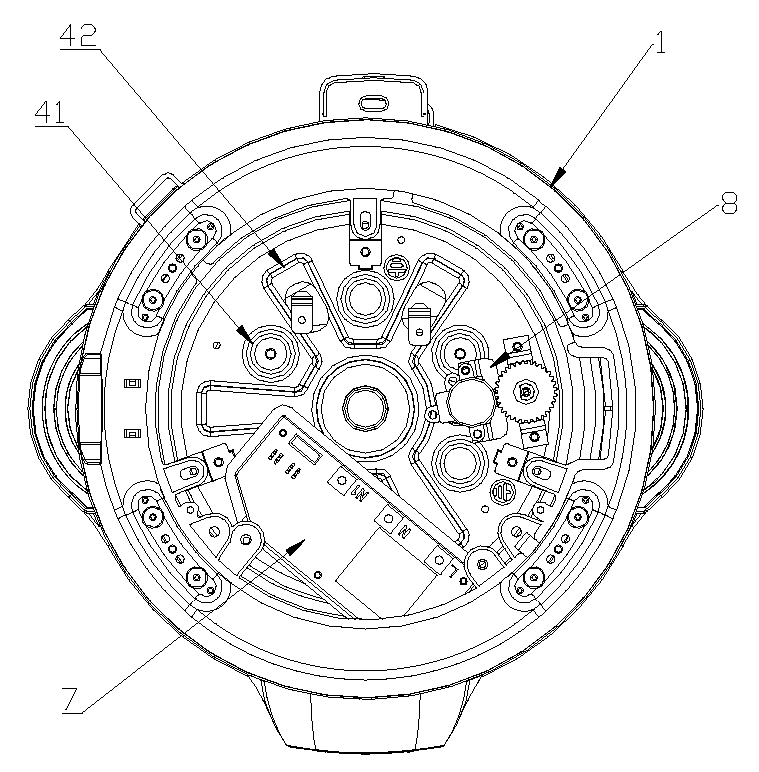

[0051] The control circuit board is arranged on the bottom of the outer pot 4, and the control circuit board is provided with a circuit control unit 7 and a heating circuit;

[0052] The pressure travel switch 9 is arranged on the bottom of the outer surface of the outer pot 4, the pressure travel switch 9 is connected to the heating circuit, and the pressure travel switch 9 is electrically...

Embodiment 2

[0065] Embodiment 2 of the electric pressure cooker of a kind of full-automatic pressure regulation of the present invention sees figure 2 with image 3 , on the basis of Embodiment 1, the features not explained in this embodiment adopt the explanations in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0066] The elastic supporting device is set as a conical boss 41 integrally formed with the bottom of the outer pot 4 , and the conical boss 41 is connected with the supporting foot 51 of the heating plate 5 .

[0067] The conical boss 41 replaces the circular elastic plate that needs to be processed and produced separately in the prior art, and the conical boss 41 and the outer pot 4 can be integrally processed and formed during production without separate assembly and disassembly, so , has the advantages of simple processing, material saving, and convenient assembly and disassembly, thereby greatly saving productio...

Embodiment 3

[0079] Embodiment 3 of the method for the automatic pressure regulation of electric pressure cooker of the present invention sees Figure 1 to Figure 6 , including the following steps:

[0080] Step a, according to the type of food to be cooked, select the control button of the corresponding food type (such as rice, meat, etc.) on the control panel 6, and the function control unit determines the automatic cooking speed of the food type according to the set intelligent program. Adjust the pressure value to P, and then the function control unit sends a pulse voltage value to the circuit control unit 7, and the circuit control unit 7 determines that the commanded working pressure value is P;

[0081] Step b. The initial set reference working pressure value of the electric pressure cooker is P O , the circuit control unit 7 sets the working pressure as the reference working pressure value P O The pressure signal is fed back to the functional control unit, and then the intelligen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com