Frustum diffusion grader

A classifier and edge platform technology, which is applied in solid separation, filter screen, grille, etc., can solve the problems of difficult large flow screening, low screening efficiency, and fast wear of components, so as to achieve low energy consumption and increase unit area. Processing power, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

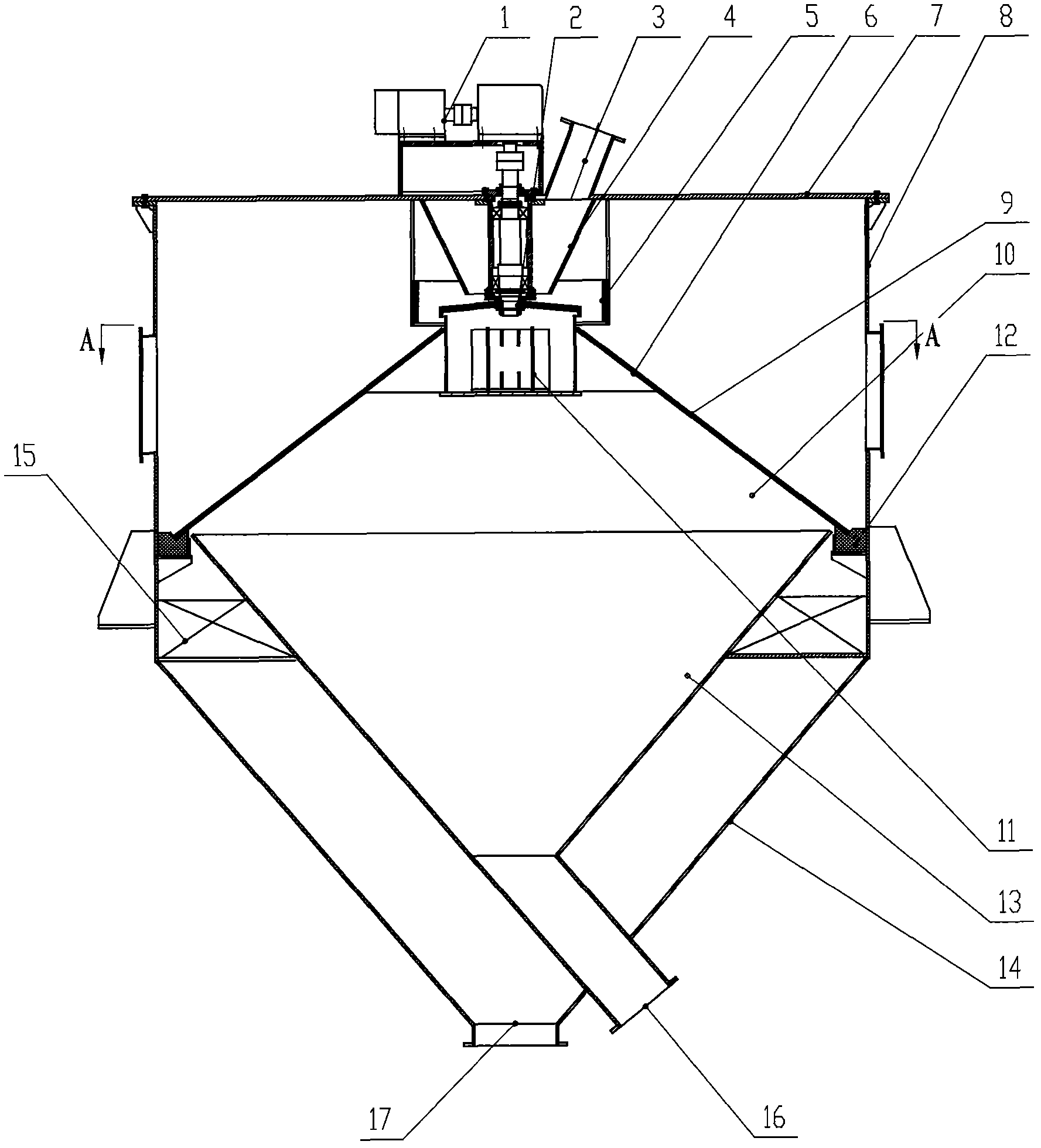

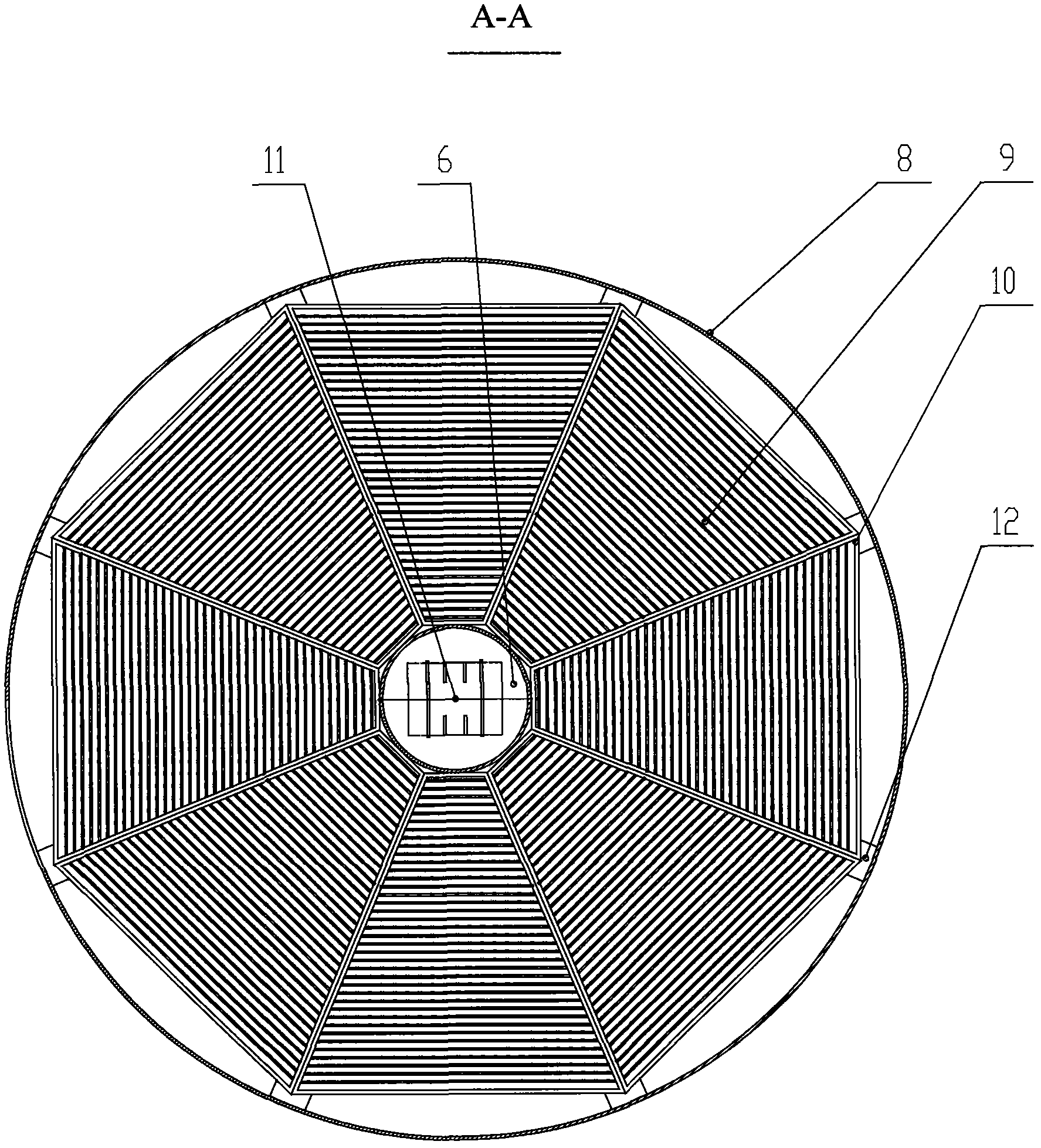

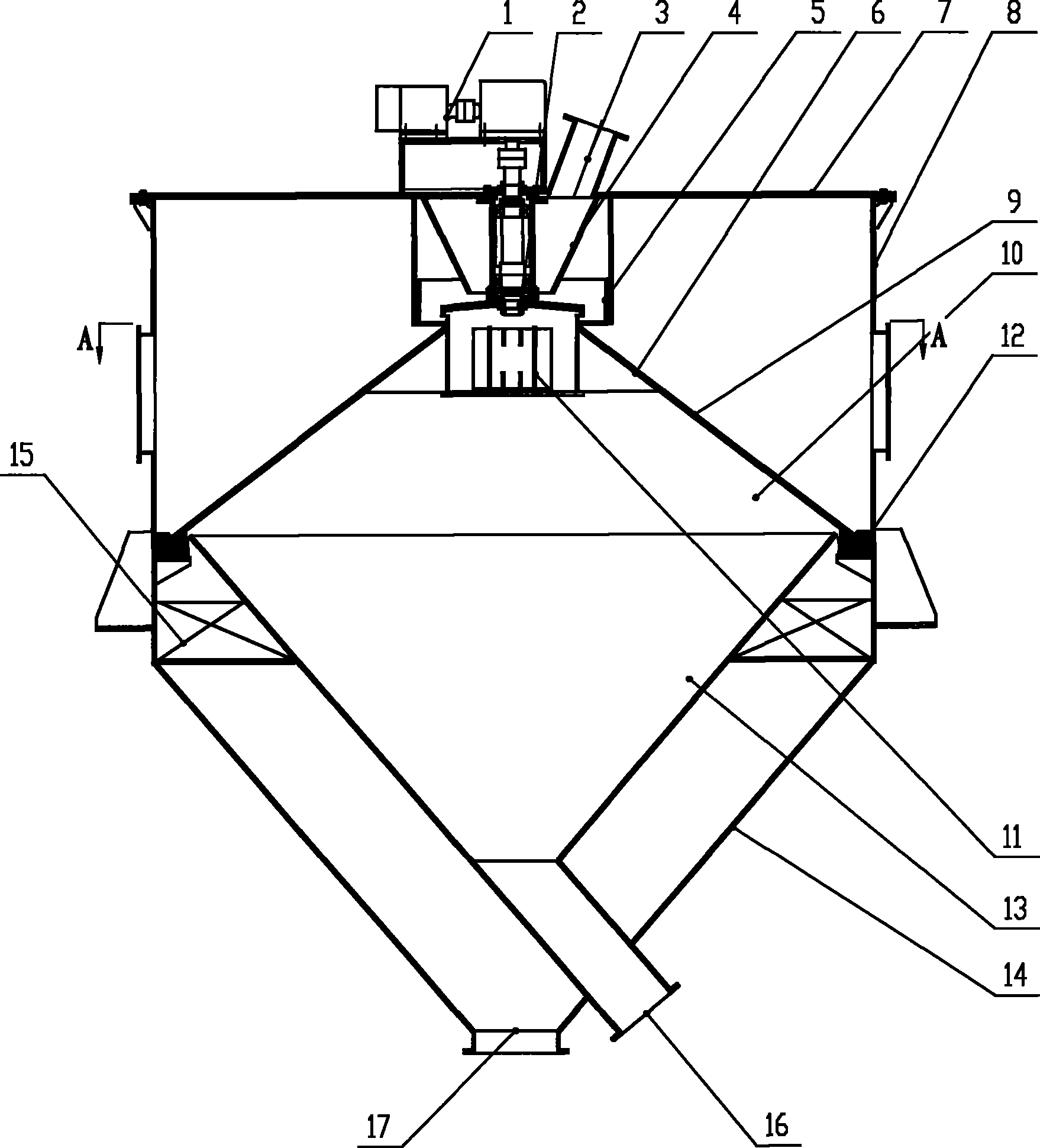

[0012] like figure 1 As shown, the pyramid diffusion classifier consists of a speed-regulating transmission device 1, a spreading disc 2, a feed hopper 3, a hopper 4, a retaining ring 5, a pyramid diffusion vibrating screen 6, an inner cone 13, an outer cone 14, Cylinder 8 is composed. Spreading plate 2, which is driven by the speed-regulating transmission device 1 installed on the top cover 7 of the cylinder body 8; the retaining ring 5 is inverted under the top cover 7 of the cylinder body 8, and forms a ring with the outer edge of the spreading plate 2 shaped unloading space. like figure 1 , figure 2 As shown, the prism diffusion vibrating screen 6 includes an upright prism-shaped screen frame 10, and a set of trapezoidal sieve sheets corresponding to each trapezoidal screen frame of the prism-shaped screen frame 10 is embedded in the screen frame to form a prism diffusion screen as a whole. Type sieve surface 9, a vibrating motor 11 is installed on the upper part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com