Side edge sealing device for double-crawler machine

An edge banding device and double crawler technology, which is applied in the field of lateral edge banding devices of double track machines, can solve the problems of unstable production of thick plates, affecting the quality of edges, and the inability of modules to extend into the middle of double track machines, etc., to achieve Improved stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

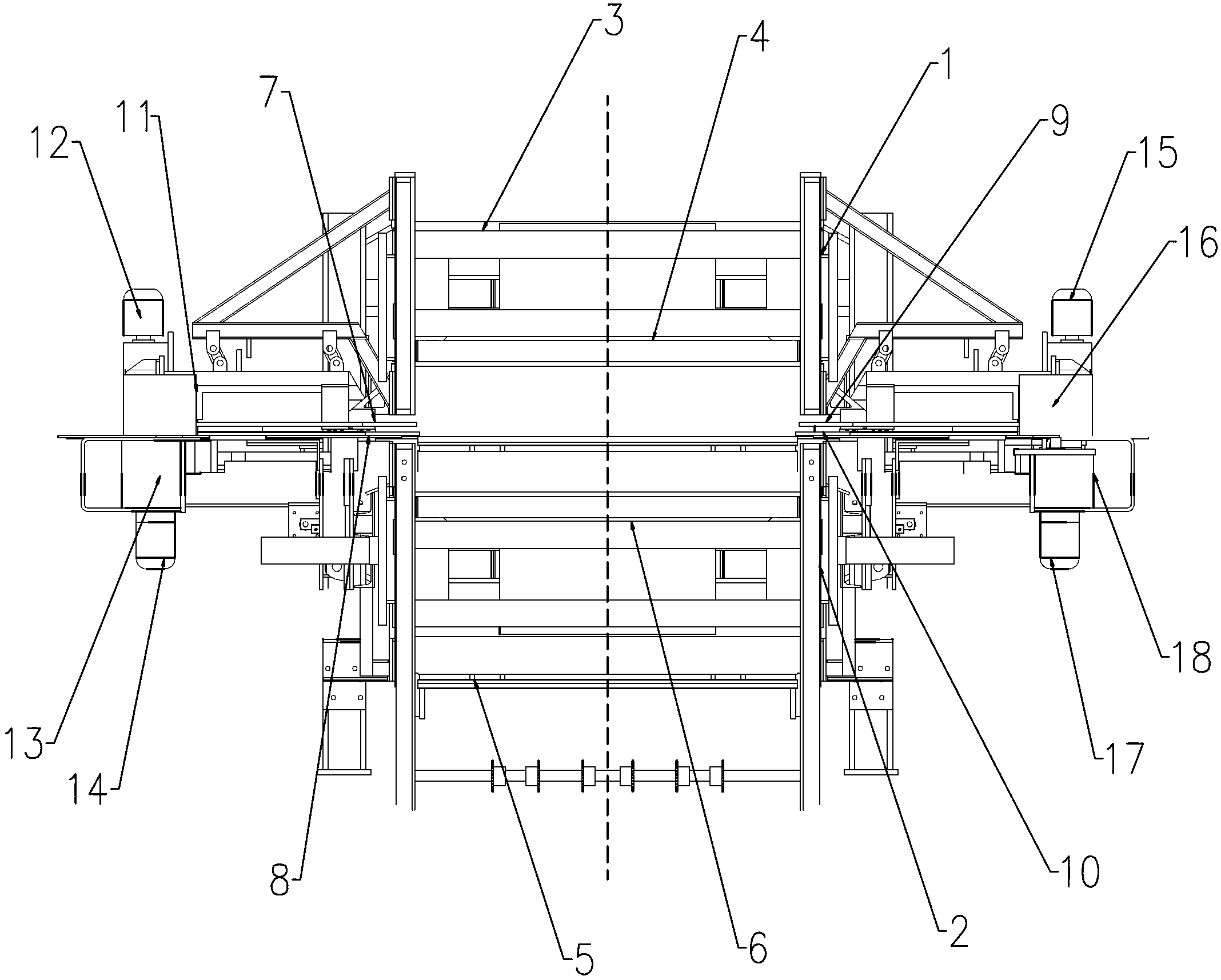

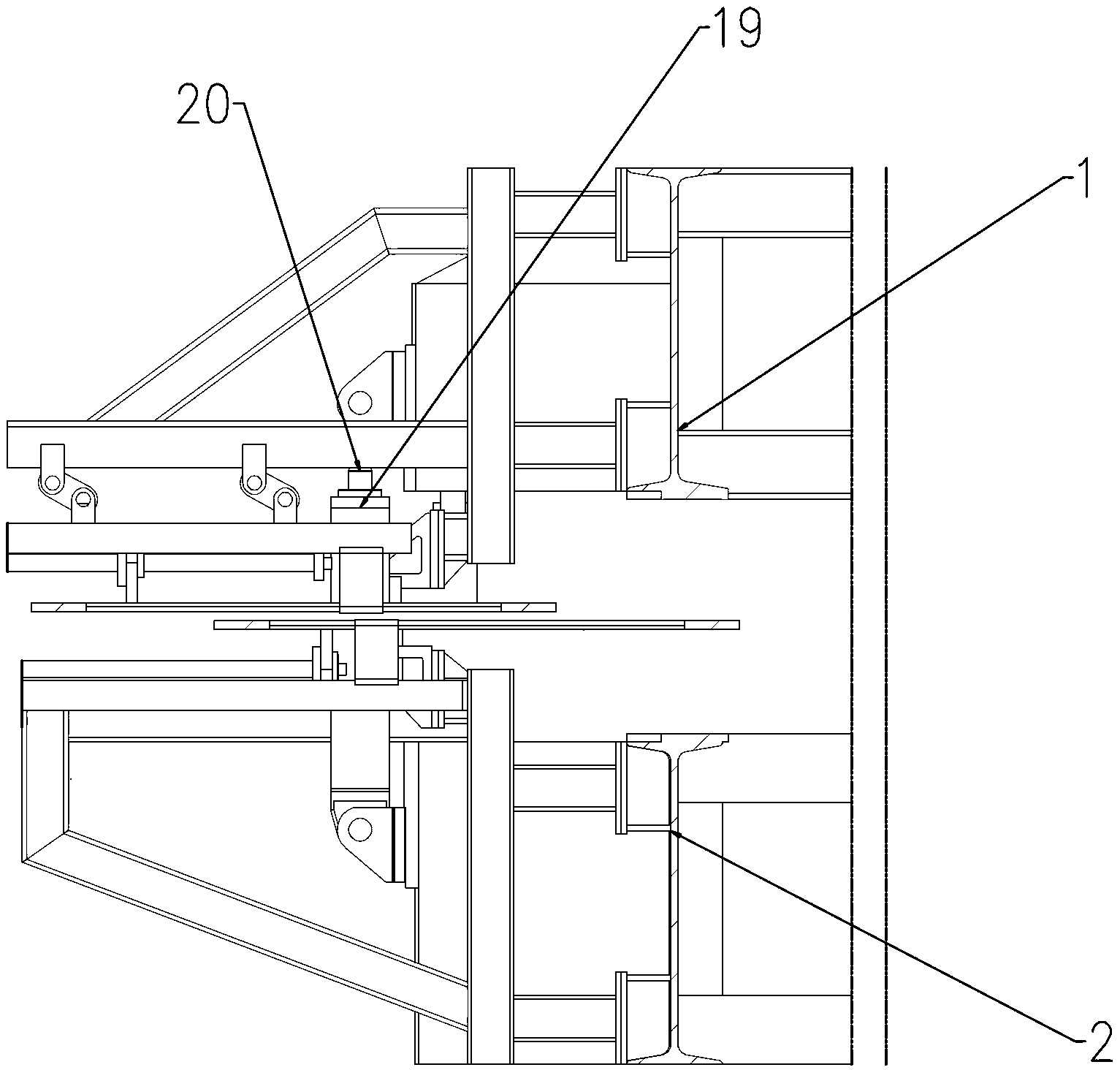

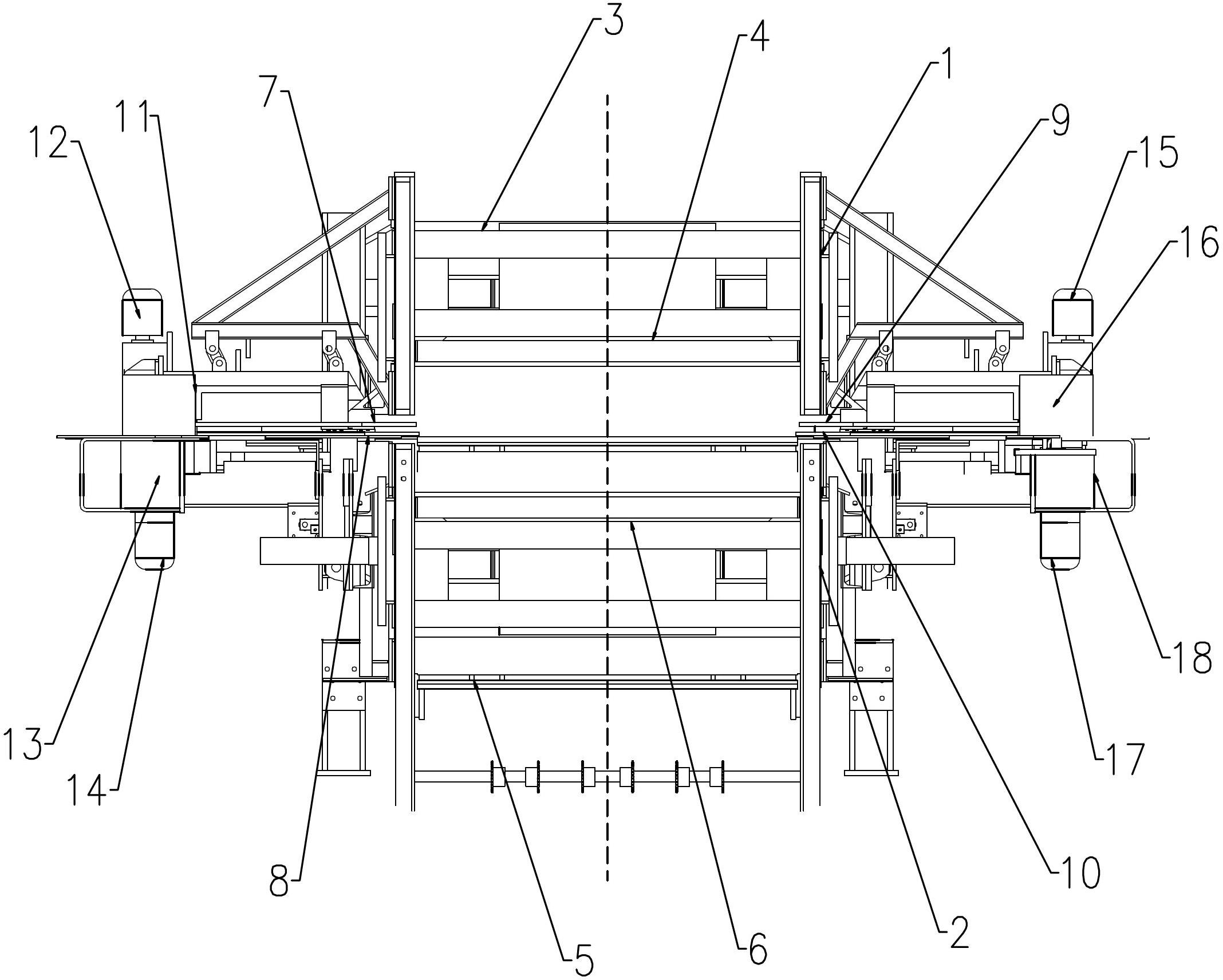

[0015] like Figure 1~2 As shown, the present invention mainly includes an upper bracket 1, a lower bracket 2, an upper left edge band 7, a lower left edge band 8, an upper right edge band 9 and a lower right edge band 10, and the upper bracket 1 is provided with an upper bracket The upper support 3 and the lower support 4 of the upper support, the lower support 2 is provided with the lower support 5 of the lower support and the upper support 6 of the lower support.

[0016] Between the upper bracket 1 and the lower bracket 2 are provided an upper left edge banding plate 7 , a lower left edge banding plate 8 , an upper right edge banding plate 9 and a lower right edge banding plate 10 . Mount left upper edge banding motor 12 and right upper edge banding motor 16 on the left and right sides of upper support 5, left upper edge banding motor 12 and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com