Compound device for seamlessly embroidered wall cloth

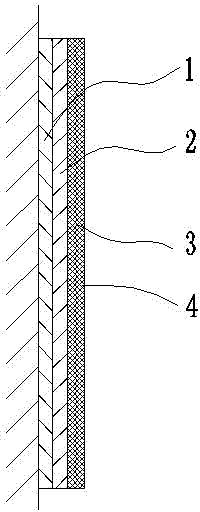

A kind of composite equipment and embroidery technology, which is applied in the field of decorative decorative materials production equipment, can solve the problems of easy wrinkling and low artistry of wall coverings, and achieve the effect of not easy wrinkling, good artistry and appreciation, and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

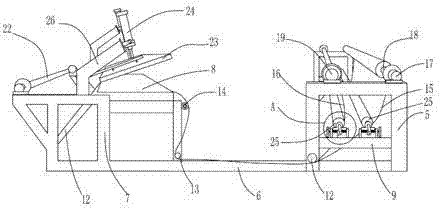

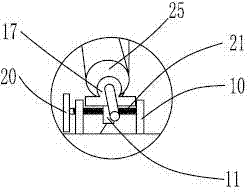

[0026] Such as figure 1 and figure 2 A composite device for seamless embroidered wall covering is shown, the composite device includes a roller mechanism for storing embroidered cloth and wallpaper base paper, a heat press mechanism for thermally pressing and laminating the embroidered cloth and wallpaper base paper, and a The frame for fixing the roller mechanism and the hot pressing mechanism, the roller mechanism and the hot pressing mechanism are fixed on the frame at intervals; the roller mechanism includes two material rollers for winding embroidered cloth and for winding wallpaper base paper respectively , that is, the embroidery roller shaft 19 and the wallpaper base paper roll shaft 18, and the control roller shaft 25 that controls the feeding direction of the embroidery cloth and wallpaper base paper respectively, and the embroidery cloth roller shaft 19 and the wallpaper base paper roll shaft 18 are respectively fixed by two shaft end covers On the frame, the cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com