Sticking method of strain gauge for differential strain test piece

A strain gauge and differential strain technology, which is applied in the field of strain gauge bonding of differential strain test pieces, can solve problems such as strain gauges are easy to fall off, errors or delays are easy to occur, and the confining pressure of the test piece is increased, so as to improve the success rate of experiments and paste The method is simple and the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

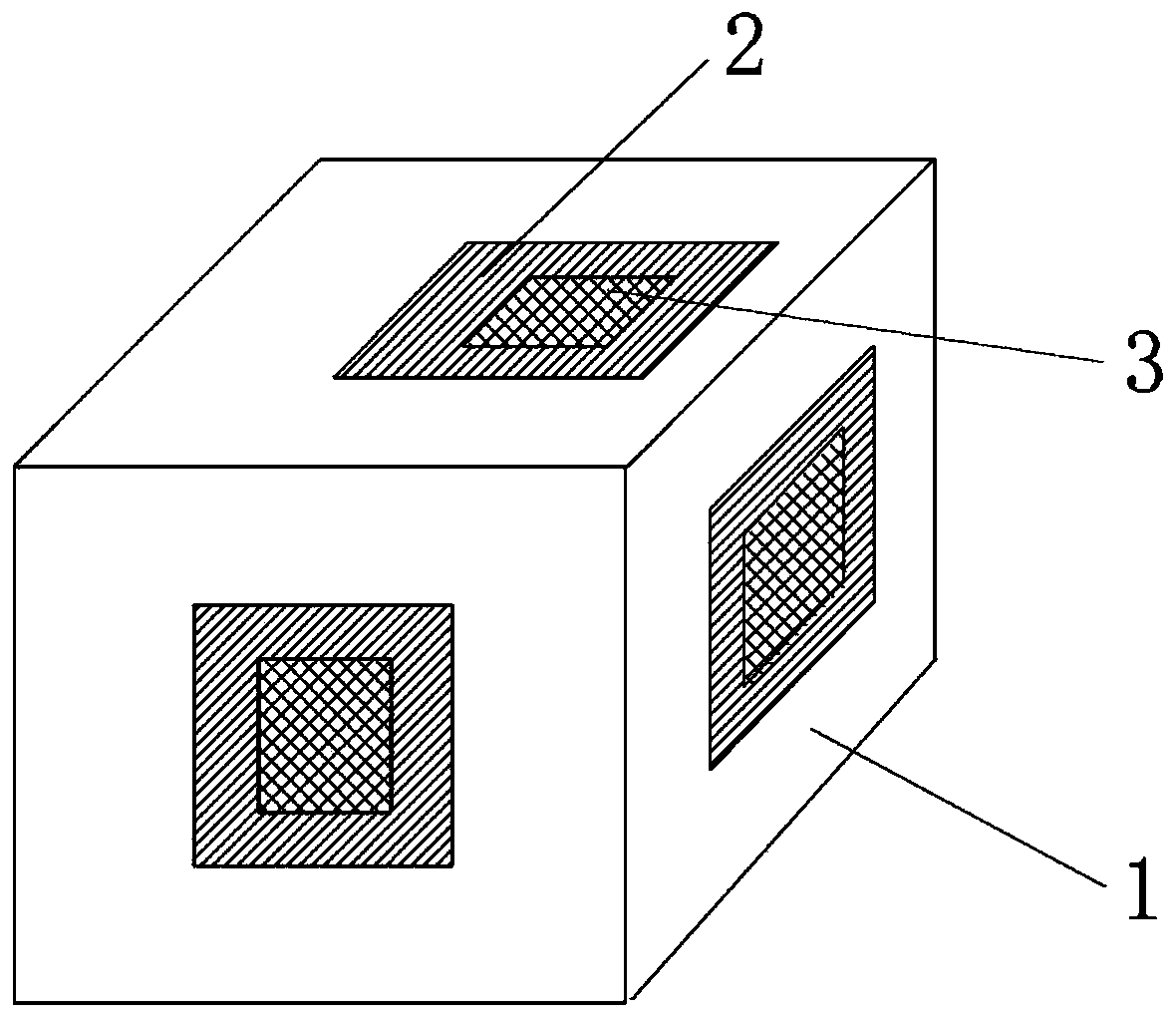

[0028] A method for pasting strain gauges of differential strain specimens, comprising the following steps:

[0029] (1) Make a copper foil 2 whose length is twice the length of the strain gauge (5mm) and whose width is twice the width of the strain gauge (10mm). The size of the copper foil 2 is 10mm×20mm and the thickness is 0.18mm. Use a rubber rod Flatten the copper foil 2 until there are no bumps or scratches;

[0030] (2) Wipe the surface of test piece 1 with a cotton swab dipped in absolute alcohol until the cotton swab no longer turns black to ensure that the surface of test piece 1 is clean;

[0031] (3), apply AB glue on the back of copper foil 2 in step (1), and paste the copper foil 2 on the surface of test piece 1 in step (2);

[0032] (4) Cover the copper foil 2 with a layer of polyvinyl chloride film, and squeeze out excess glue and air bubbles under the copper foil 2 along the long side of the copper foil;

[0033] (5) Open the polyvinyl chloride film to check...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com