Adhesive layer bonding device and method

A sticking device and adhesive layer technology, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problem of separation of the adhesive layer and the board, and achieve simple structure, simple adhesive layer pasting method, and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Unless otherwise defined, all technical terms used in the embodiments of the present invention have the same meanings as commonly understood by those skilled in the art. Before further describing the embodiments of the present invention in detail, some terms for understanding the embodiments of the present invention are defined.

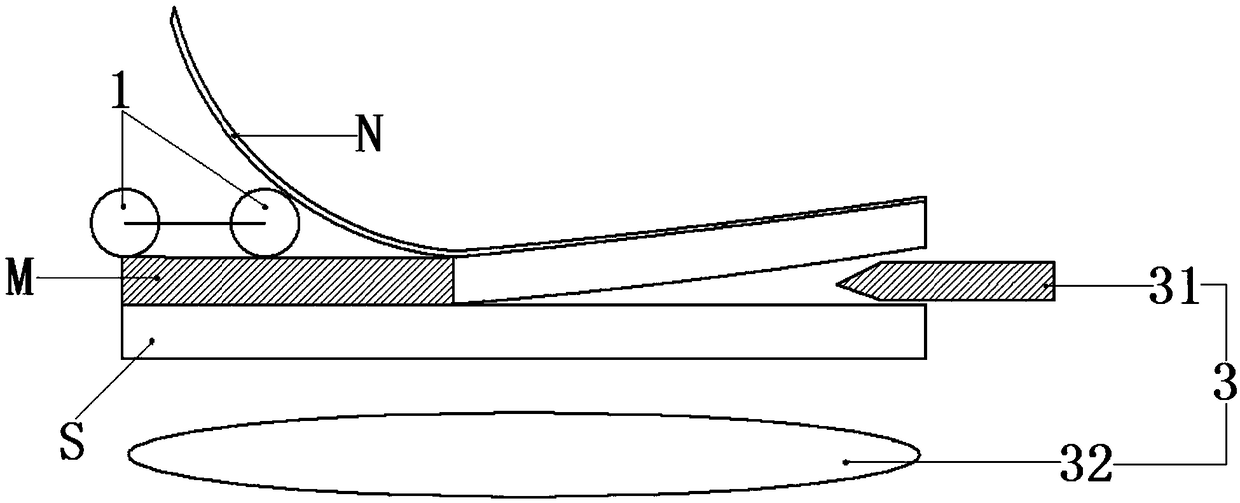

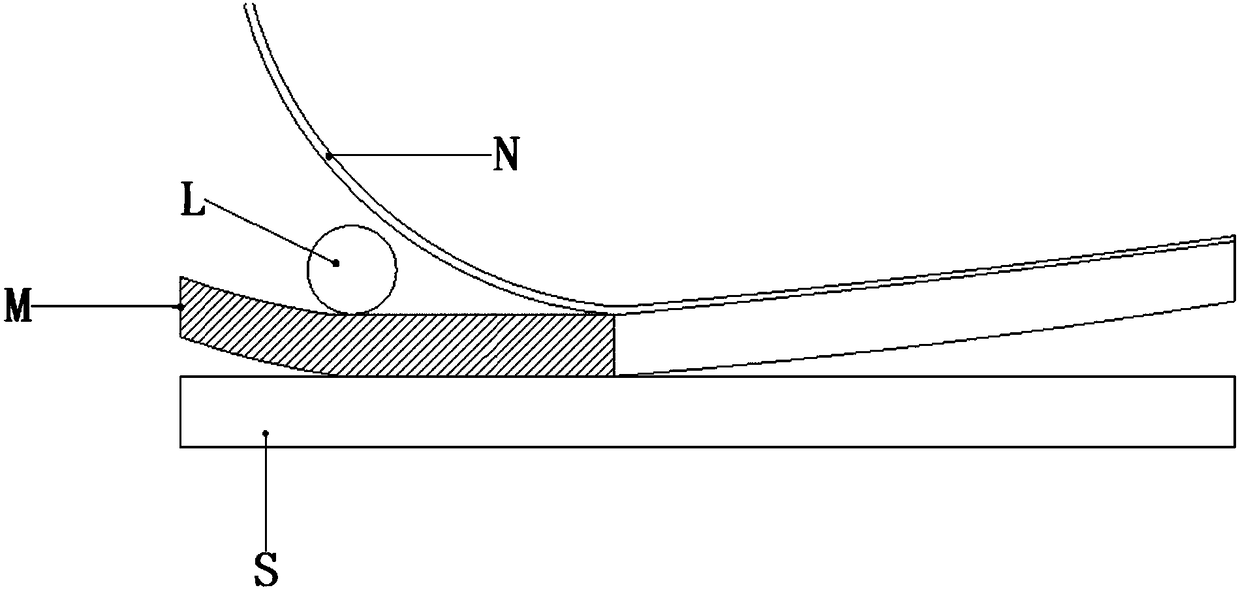

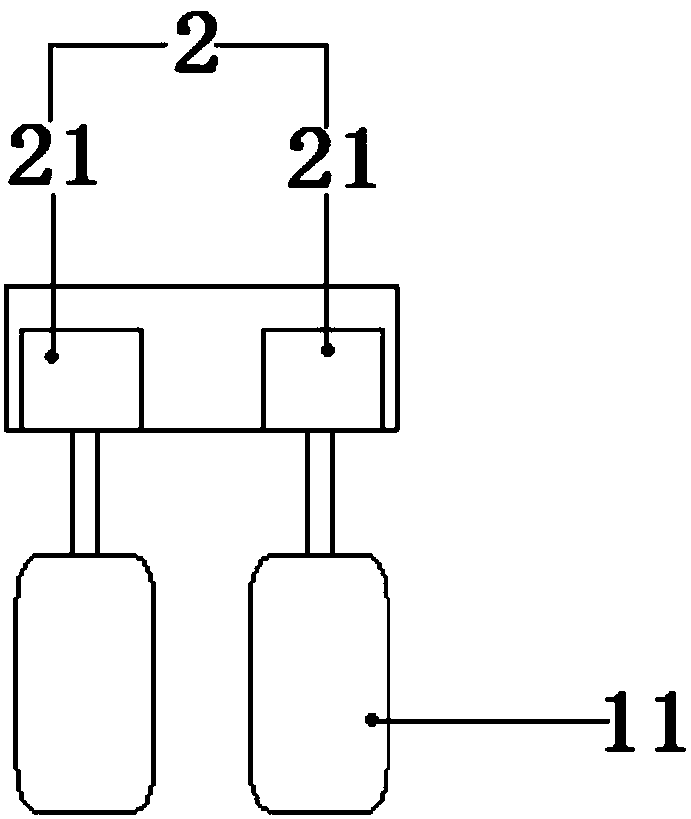

[0068] In the embodiment of the present invention, the "first adhesive surface" and "second adhesive surface" involved are two opposite adhesive surfaces in the adhesive covering layer M.

[0069] A release film N is arranged on the first sticking surface of the adhesive covering layer M, and when the adhesive covering layer M is rolled together, the release film N separates the first sticking surface and the second sticking surface of the adhesive covering layer M .

[0070] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com