Accumulation type conveyor

A technology of accumulating and releasing conveyor and host system, applied in the direction of conveyor, transportation and packaging, can solve problems such as the impact of enterprise production, and achieve the effect of small footprint, improved applicability, and high space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

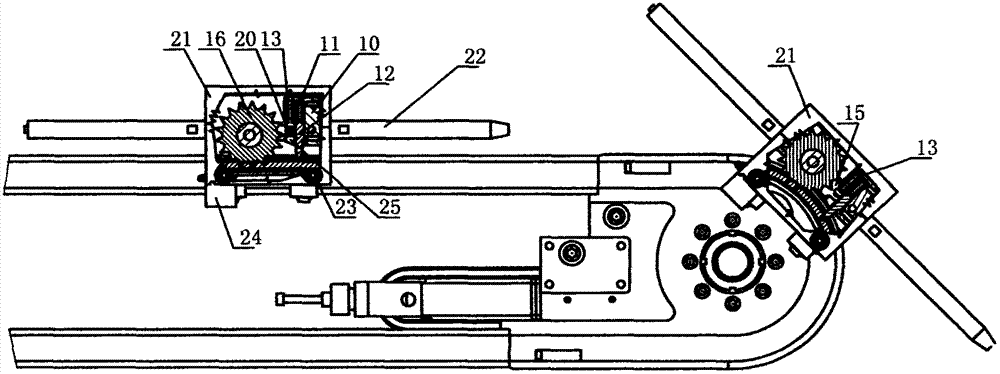

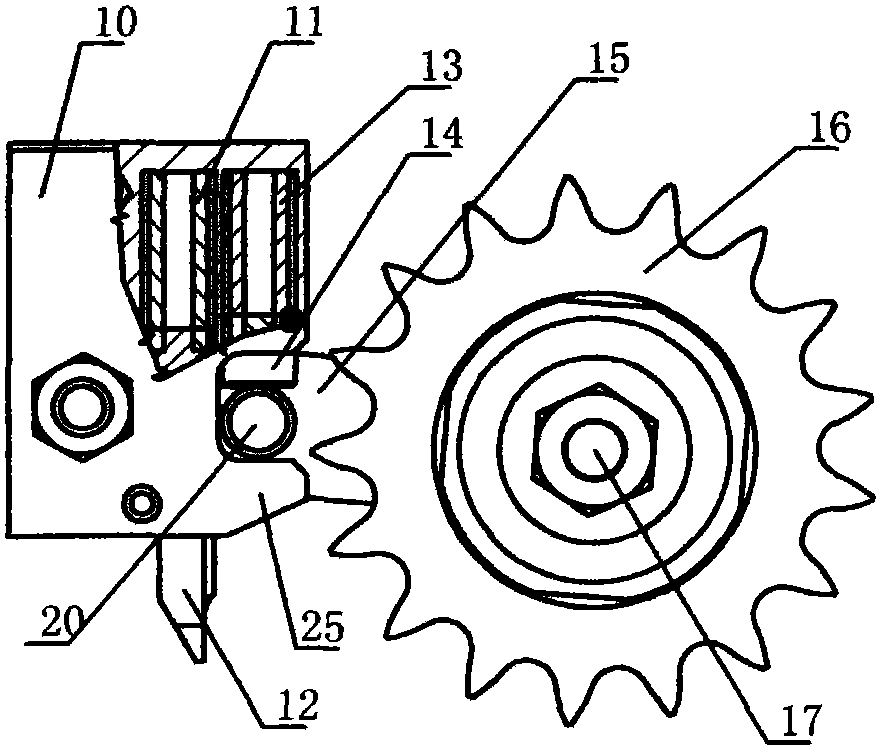

[0012] The center of the present invention is to design a traction mechanism used in conjunction with the pallet system. Under the premise of ensuring that the pallet system can be turned up and down freely, it can better realize the flexible transportation and combination of the pallet system, so as to improve the flexibility of the conveyor. sex and convenience.

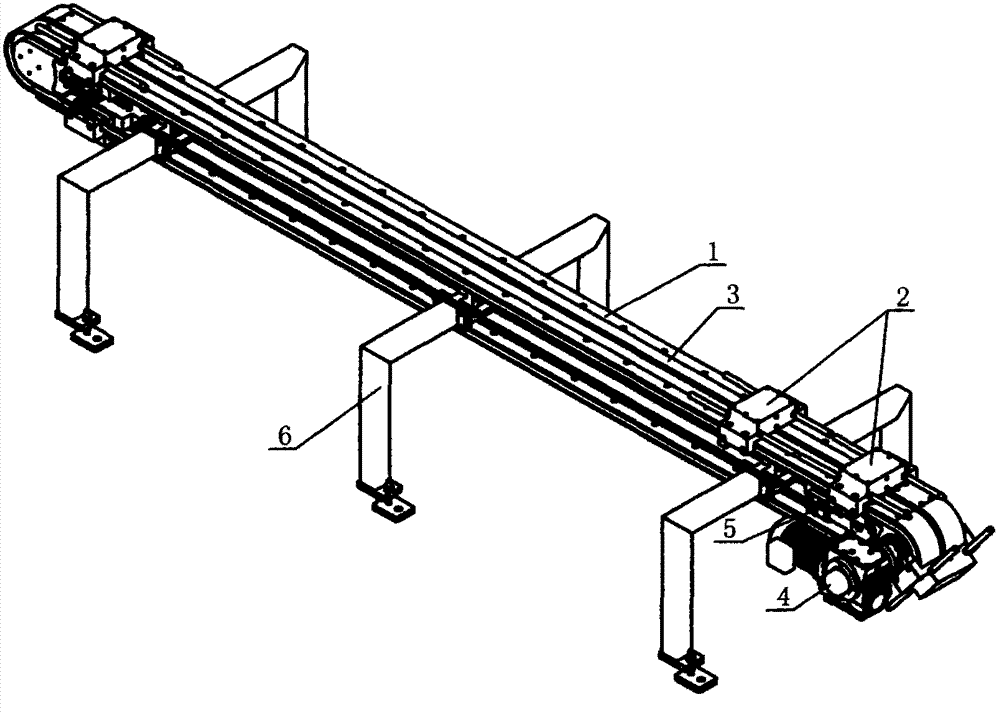

[0013] Attached below figure 1 , figure 2 , image 3 , Figure 4 The present invention is further described:

[0014] The accumulation conveyor of the present invention includes a host system 1 and a pallet system 2 connected to the host system 1 . The host system 1 is the supporting body of the entire conveyor, and plays the role of guiding and conveying the pallet system 2 . The tray system 2 is a moving body, which is used to carry products or materials to form automatic transmission of products or materials to complete the assembly process.

[0015] The host system 1 mainly includes a chain transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com