Automatic production equipment for invisible screen windows

An automatic production, invisible screen technology, applied in the directions of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of unguaranteed quality, low production efficiency of invisible screens, etc., and achieves good verticality, improved market competitiveness, and cutting The effect of material regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

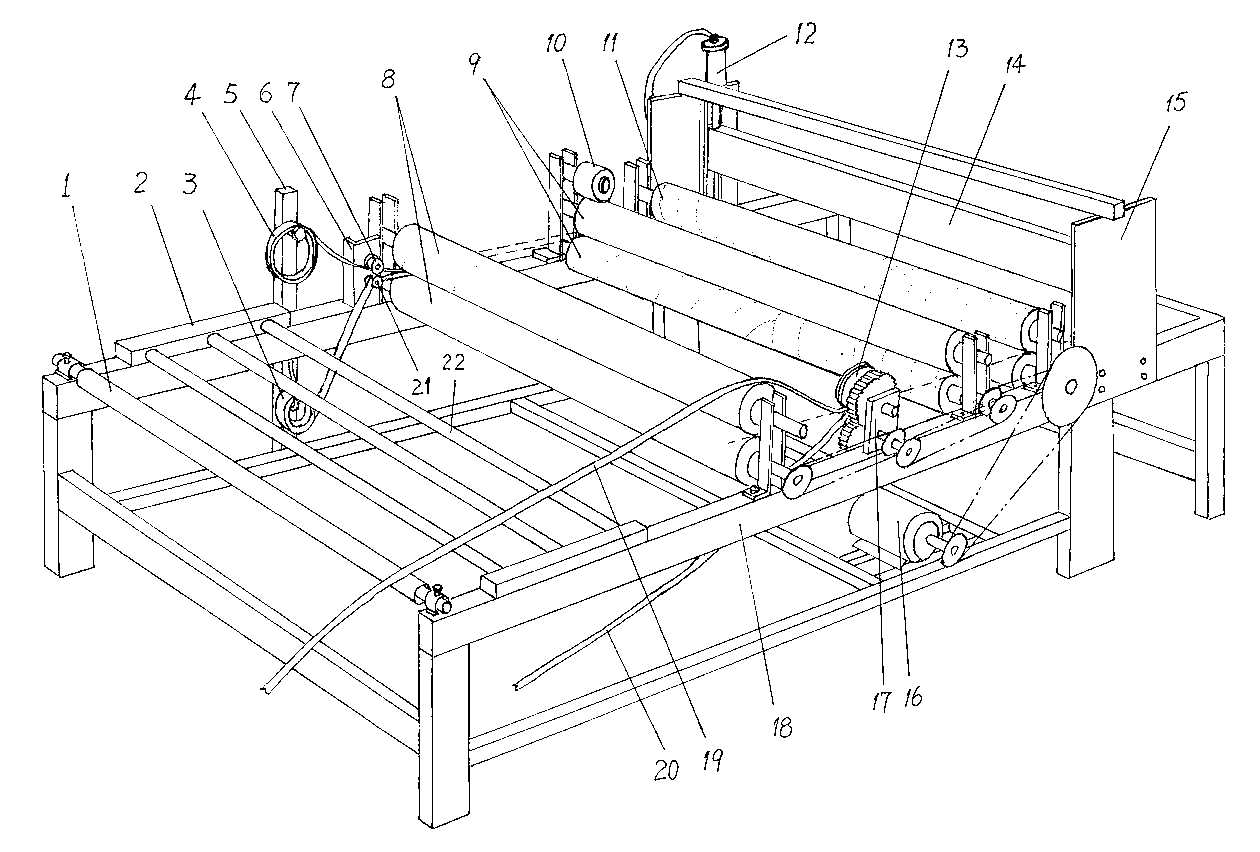

[0018] Such as figure 1 As shown, the frame 18 is a rectangular frame, and a shaft is installed on the front end of the frame 18, and the yarn guide roller 1 is sleeved on the shaft, so as to realize the first-level adjustment from the yarn roll to the flat laying of the yarn surface. The frame 18 at the yarn guide roller 1 rear portion is provided with a yarn surface adjuster, so that the yarn surface pulled over remains smooth and realizes the secondary adjustment of the yarn surface. Described yarn surface adjuster is to be connected with three horizontal bars 22 that are arranged in parallel between two horizontal side frames 2, and two side frames 2 are fixedly connected on the frame of frame 18. The yarn surface passes through the upper and lower sides of the guide roller 1 and the three cross bars 22 sequentially, forming a wave-shaped traction adjustment situation, so that the drawn yarn surface becomes smooth.

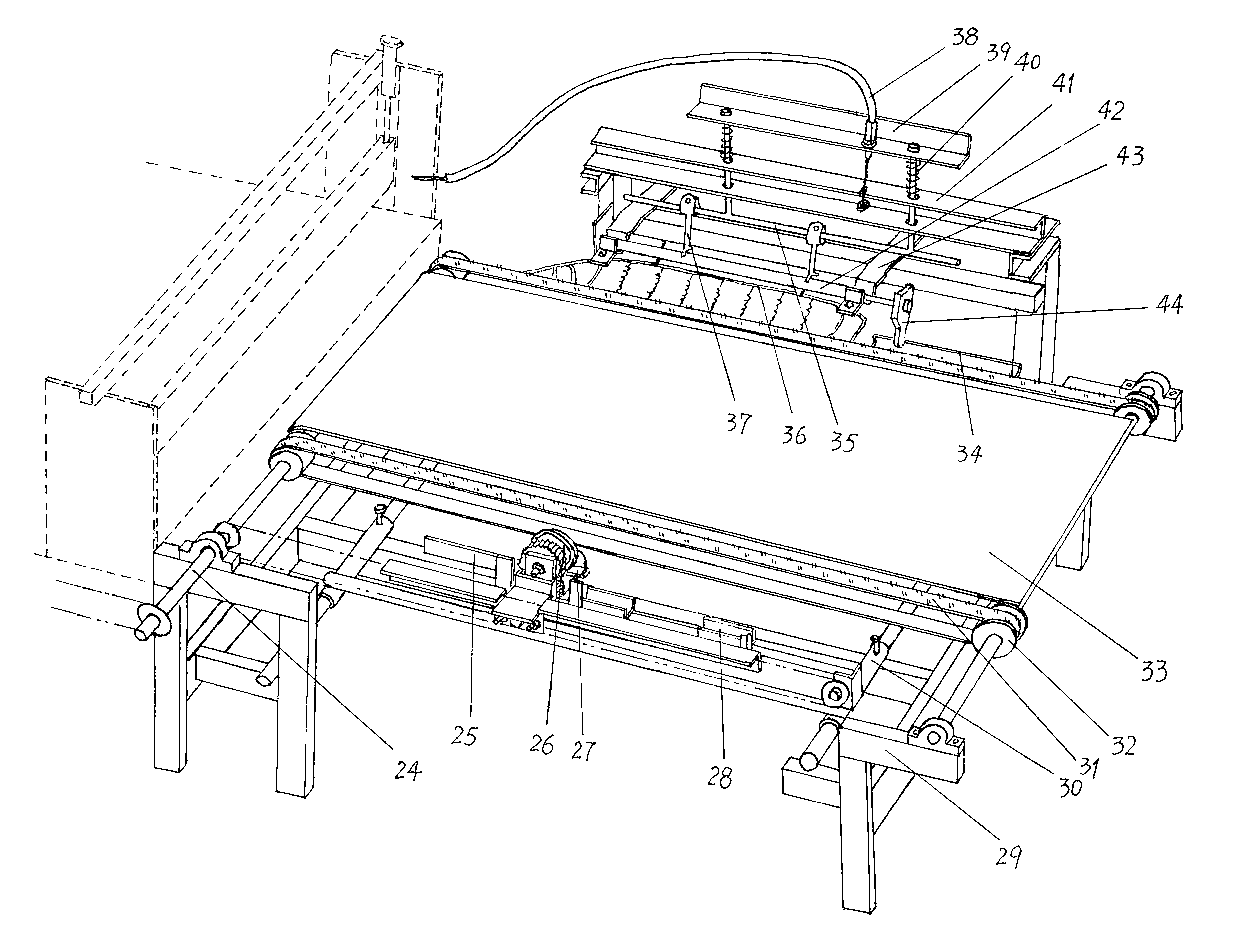

[0019] The top surface of frame 18, the rear portion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com