Method and device for preparing stannic oxide powder

A technology of tin dioxide powder and tin powder, which is applied in the direction of tin oxide, etc., can solve the problems of high cost, long technical process of powder production, and difficulty in industrialization, and achieve the effects of low cost, reduced manual operation, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

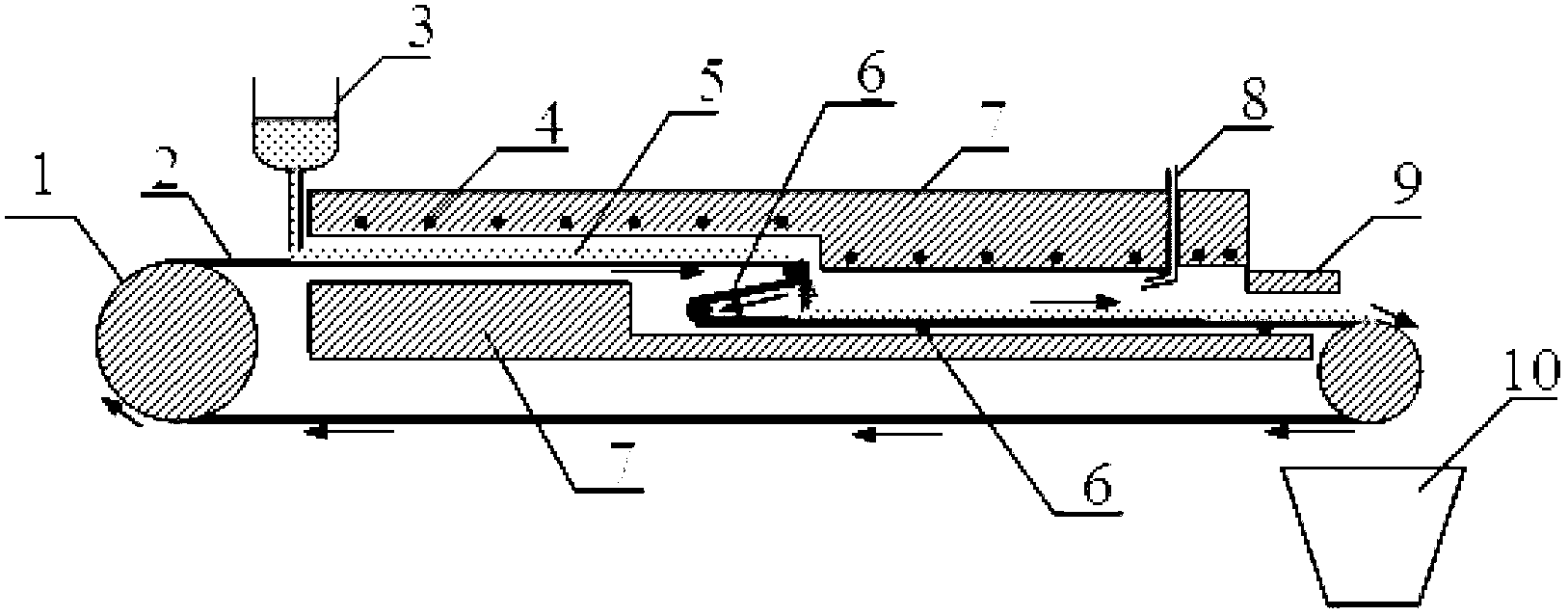

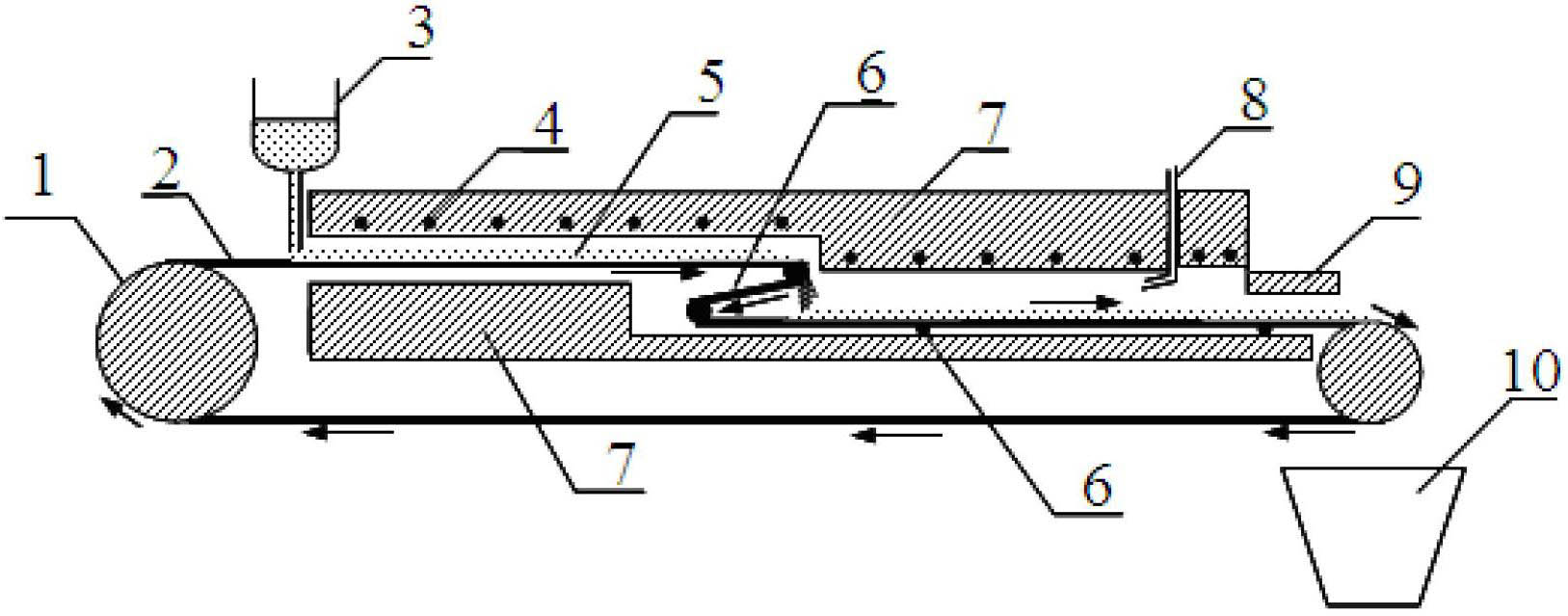

Embodiment 1

[0036] Firstly, 1000g of tin powder with an average particle size of about 500nm is prepared by the spray powder method; then the tin powder is placed in the automatic feeding mechanism ③, and the distance between the automatic feeding mechanism and the stainless steel belt is adjusted to control the thickness of the tin powder layer It is 3mm. Start the electric roller rotating device and set the pre-oxidation temperature to 200°C. The horizontal distance between the two stainless steel rollers in the "Z"-shaped turning mechanism is 30cm, and the longitudinal height difference is 10cm. Blow air with an air flow of 5.5L / h from the air supply hole ⑧, and the pre-oxidation time is 30min. The secondary oxidation temperature is 550℃, the air flow rate is 5.5L / h, and the secondary oxidation time is 60min. After the reaction, SnO is obtained 2 The powder is 1268.3g, the oxidation rate is 99.89%.

Embodiment 2

[0038] First, make 10Kg of tin powder with an average particle size of about 1μm by spraying powder method. Put the tin powder in the automatic feeding mechanism ③, adjust the distance between the automatic feeding mechanism and the stainless steel belt, and control the thickness of the tin powder layer to 5mm. The horizontal distance between the two stainless steel rollers in the "Z"-shaped turning mechanism is 10cm, and the longitudinal height difference is 20cm. Start the electric roller rotating device and set the pre-oxidation temperature to 225°C. Blow in air with an air flow of 7L / h from the air supply hole ⑧, and the pre-oxidation time is 40 minutes. The secondary oxidation temperature is 600℃, the air flow rate is 7L / h, and the secondary oxidation time is 90min. After the reaction, SnO is obtained 2 The powder is 12.69Kg, the oxidation rate is 99.95%.

Embodiment 3

[0040] First, 100Kg of tin powder with an average particle size of about 0.8μm is prepared by spraying powder method. The tin powder is placed in the automatic feeding mechanism ③, and the distance between the automatic feeding mechanism and the stainless steel belt is adjusted to control the thickness of the tin powder layer It is 12mm. The horizontal distance between the two stainless steel rollers in the "Z"-shaped turning mechanism is 60cm, and the longitudinal height difference is 40cm. Start the electric roller rotating device and set the pre-oxidation temperature to 230°C. Blow air with an air flow of 10L / h from the air supply hole ⑧, and the pre-oxidation time is 60min. The secondary oxidation temperature is 700℃, the air flow rate is 10L / h, and the secondary oxidation time is 180min. After the reaction, SnO is obtained 2 The powder is 126.86Kg, the oxidation rate is 99.92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com